A kind of water-based stain-resistant white finish for woodware and preparation method thereof

A technology for white finish paint and woodware, applied to biocide-containing paints, antifouling/underwater paints, coatings, etc., can solve the problems of poor stain resistance and difficulty in high-end furniture, and achieve low VOC content and excellent adhesion Good effect of strong force and scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

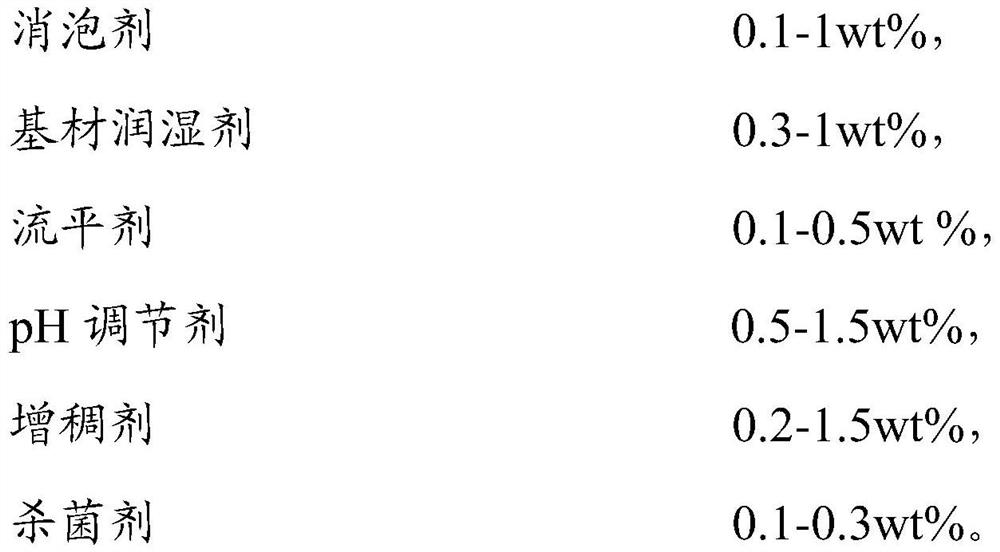

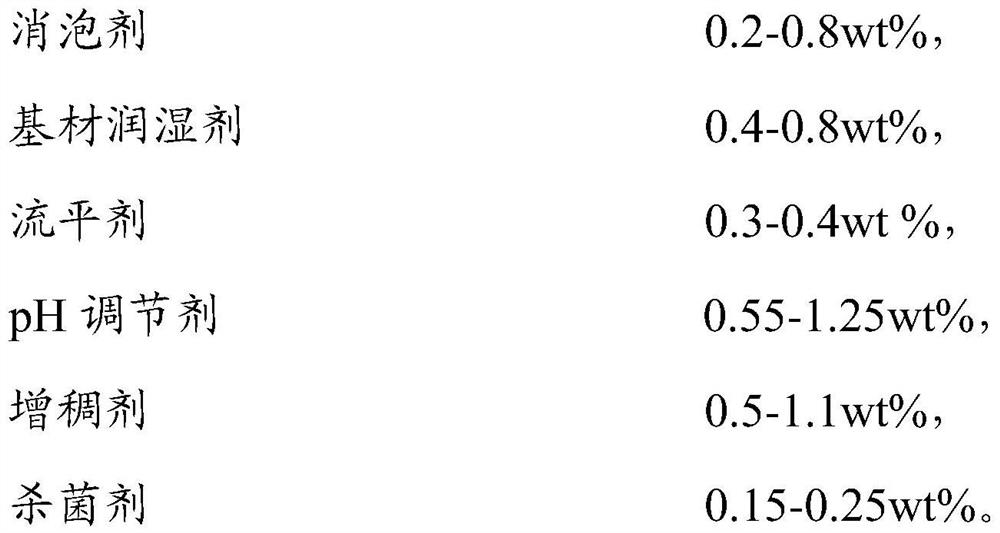

Method used

Image

Examples

Embodiment 1

[0097] The preparation of the aqueous acrylic polymer emulsion a of core-shell structure:

[0098] (1) Preparation of nuclear layer pre-emulsion: 120g methyl methacrylate, 180g butyl acrylate, 1.5g sodium lauryl sulfate and 90g deionized water were respectively added to a 1L reactor for pre-emulsification, pre-emulsification The time is 30min, obtains nuclear layer pre-emulsion;

[0099] (2) Prepare the shell pre-emulsion: add 230g methyl methacrylate, 54g butyl acrylate, 15g acrylic acid, 1.5g sodium lauryl sulfate and 90g deionized water to a 1L reactor for pre-emulsification , the pre-emulsification time is 30min to obtain the shell layer pre-emulsion;

[0100] (3) Preparation of seed emulsion: Add 1.2g of sodium lauryl sulfate, 680g of water and 18g of the nuclear layer pre-emulsion obtained in step (1) into a 3L reactor, start stirring and heating, and wait until the temperature rises to 85°C. Add 12g aqueous initiator solution containing 1.5g ammonium persulfate to ini...

Embodiment 2

[0117] The preparation of the aqueous acrylic polymer emulsion b of core-shell structure:

[0118] (1) Preparation of nuclear layer pre-emulsion: 150g methyl methacrylate, 150g butyl acrylate, 1.5g sodium lauryl sulfate and 90g deionized water were added to a 1L reactor for pre-emulsification, pre-emulsification The time is 30min, obtains nuclear layer pre-emulsion;

[0119] (2) Prepare the shell pre-emulsion: add 260g of methyl methacrylate, 24g of butyl acrylate, 15g of acrylic acid, 1.5g of sodium lauryl sulfate and 90g of deionized water into a 1L reactor for pre-emulsification , the pre-emulsification time is 30min to obtain the shell layer pre-emulsion;

[0120] (3) Preparation of seed emulsion: Add 1.2g of sodium lauryl sulfate, 680g of water and 18g of the nuclear layer pre-emulsion obtained in step (1) into a 3L reactor, start stirring and heating, and wait until the temperature rises to 85°C. Add 12g aqueous initiator solution containing 1.5g ammonium persulfate to...

Embodiment 3

[0137] Preparation of water-based acrylic polymer emulsion c of core-shell structure:

[0138] (1) Preparation of nuclear layer pre-emulsion: 200g methyl methacrylate, 200g butyl acrylate, 2g sodium lauryl sulfate and 120g deionized water are respectively added to a 1L reactor for pre-emulsification. The time is 30min to obtain the core layer pre-emulsion;

[0139] (2) Prepare the shell layer pre-emulsion: 180g methyl methacrylate, 5g butyl acrylate, 15g acrylic acid, 1g sodium lauryl sulfate and 60g deionized water are respectively added to a 1L reactor for pre-emulsification, The time of pre-emulsification is 30min to obtain the shell layer pre-emulsion;

[0140] (3) Preparation of seed emulsion: Add 1.2g of sodium lauryl sulfate, 680g of water and 18g of the nuclear layer pre-emulsion obtained in step (1) into a 3L reactor, start stirring and heating, and wait until the temperature rises to 85°C. Add 12g aqueous initiator solution containing 1.5g ammonium persulfate to in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com