A cooling liquid for alloy ingot

An alloy ingot and cooling liquid technology, applied in the field of alloy casting, can solve the problems of high cost and complicated process, and achieve the effects of avoiding sudden temperature change, good surface gloss and good environmental protection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

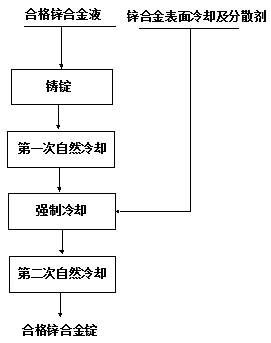

Method used

Image

Examples

Embodiment 1

[0017]An alloy ingot coolant, consisting of a weight fraction of the weight: 980 parts of water, 12 parts of alkylbenzene sulfonate, 2 sodium sulfate, 2 sodium triophosphate, 2 carboxymethylcellulose, acrylic acid 1 part, 1 sodium bicarbonate.

[0018]The cooling of the coolant using the present embodiment was cooled by the alloy: first, the zinc alloy ingot was naturally cooled to 460-480 ° C in the air, and the coolant of the present embodiment was poured to the surface of the zinc alloy ingot, 80-90 minutes. Afterward, the zinc alloy ingot is released, and the temperature of the zinc alloy ingot is: 60-80 ° C, and the qualified zinc alloy ingot is obtained after natural cooling in the air.

[0019]Detection of the cooling zinc alloy: Tested, the zinc alloy has silver white metal gloss, smooth surface, no slag, no fuse, no damage, no obvious drum, no obvious crack (less than 0.8 mm in width), Flying burrs less than 8mm, complies with YS / T 310-2008 "hot plating zinc alloy ingot" standa...

Embodiment 2

[0021]A zinc alloy ingot coolant composition consists of the following weight fraction: 989 water production, 6 parts of alkylbenzene sulfonate, 1 sodium sulfate, 1 sodium trimophosphate, 1 carboxymethylcellulose, 0.5 copies of acrylic acid, 0.5 sodium hydrogencarbonate.

[0022]The cooling of the coolant using the present embodiment was cooled by the alloy: first, the zinc alloy ingot was naturally cooled to 460-480 ° C in the air, and the coolant of the present embodiment was poured to the surface of the zinc alloy ingot, 80-90 minutes. Afterward, the zinc alloy ingot is released, and the temperature of the zinc alloy ingot is: 60-80 ° C, and the qualified zinc alloy ingot is obtained after natural cooling in the air.

[0023]Detecting the zinc alloy after cooling: Tested, the zinc alloy has silver white metal gloss, smooth surface, no slag, no fuse, no shrinkage, no obvious drum, no obvious crack (less than 0.6mm in width), Flying burrs less than 6mm, complying with YS / T 310-2008 "ho...

Embodiment 3

[0025]A zinc alloy ingot coolant consisting of 990 water production: 10 parts of water, 10 sodium alkylbenzene sulfonate, 1 sodium sulfate, and 1 tripolyphosphate.

[0026]The cooling of the coolant using the present embodiment was cooled by the alloy: first, the zinc alloy ingot was naturally cooled to 460-480 ° C in the air, and the coolant of the present embodiment was poured to the surface of the zinc alloy ingot, 80-90 minutes. Afterward, the zinc alloy ingot is released, and the temperature of the zinc alloy ingot is: 60-80 ° C, and the qualified zinc alloy ingot is obtained after natural cooling in the air.

[0027]Detecting the cooling zinc alloy: Tested, the zinc alloy has silver white metal gloss, smooth surface, no slag, no fuse, no shrinkage, no obvious drum, no obvious crack (less than 0.9mm in width), Flying burrs less than 8mm, complies with YS / T 310-2008 "hot plating zinc alloy ingot" standard requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com