Methane production system with mixed fermentation for paddy field and method thereof

A technology of mixed fermentation and biogas production, which is applied in the direction of biochemical equipment and methods, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc. It can solve the problems of increasing rural energy supply and achieve gas production Maximize efficiency and economic benefits, reduce floor space, and reduce carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

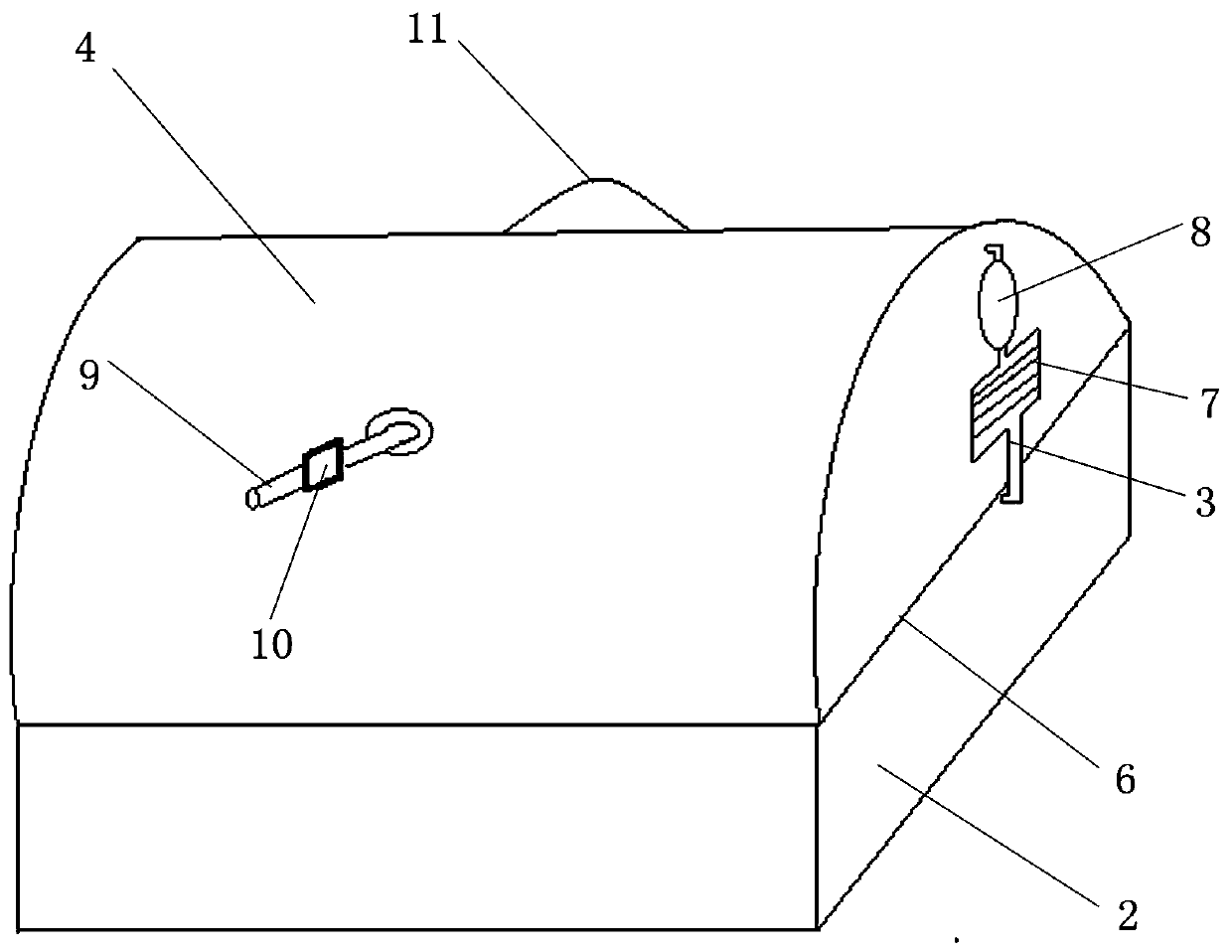

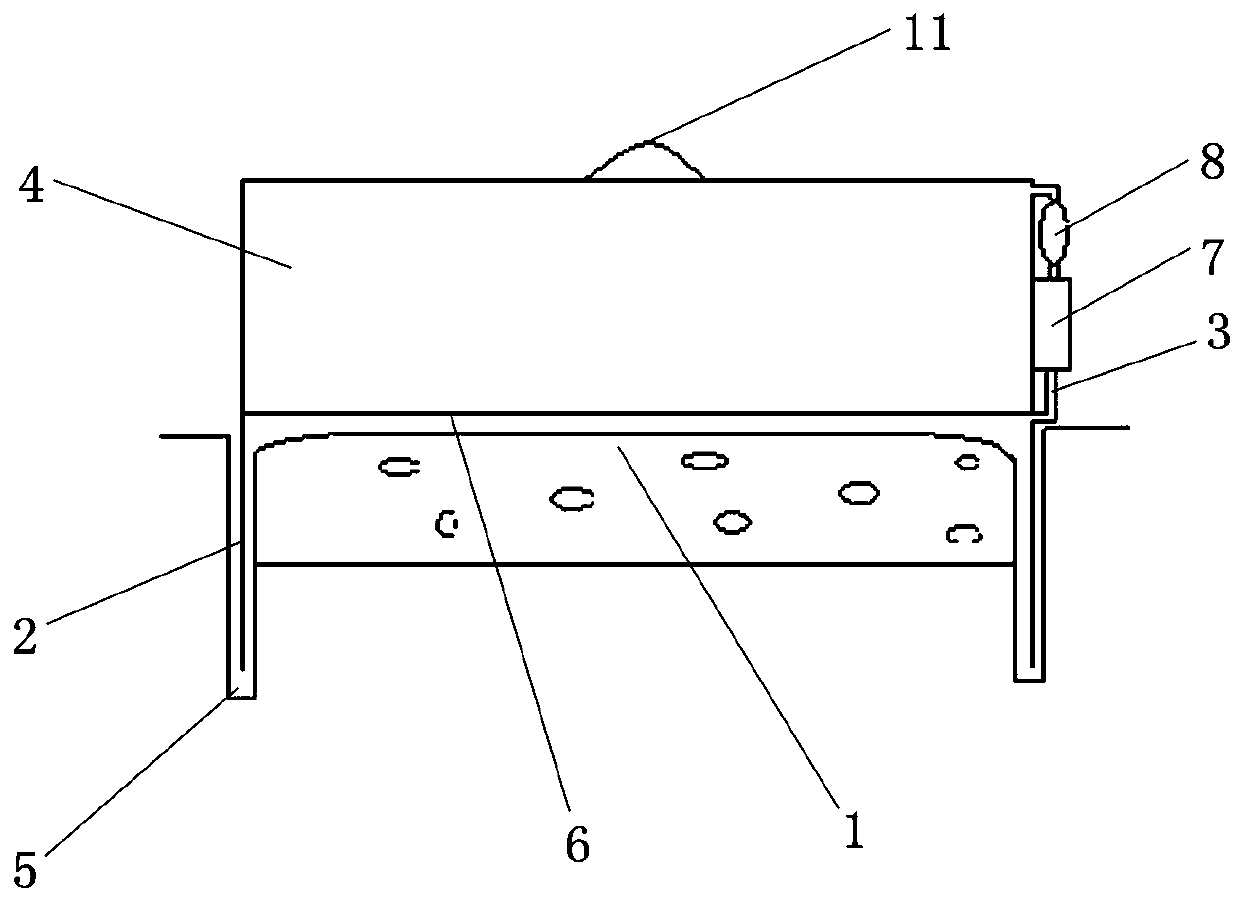

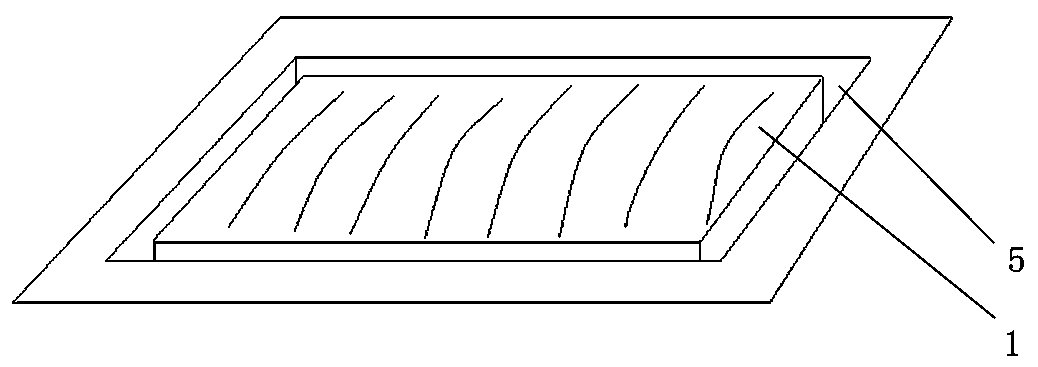

[0040] Such as Figures 1 to 3 As shown, a paddy field mixed fermentation biogas production system includes a paddy field fermentation area 1, and straw and farmyard manure are laid on the paddy field fermentation area 1. It is connected with the gas collection bin 4 through the connecting pipe 3 . In this example, the weight ratio of straw to farmyard manure is 1:1, and the types of farmyard manure can be adjusted according to local conditions. The preferred order is pig manure, biogas slurry, cow manure, and sheep manure.

[0041] Preferably, an annular ditch 5 is opened around the paddy field fermentation area 1 , and the bottom of the side wall of the fermentation bin 2 is set in the annular ditch 5 .

[0042] Preferably, the fermentation chamber 2 is a hollow cuboid structure with open top and bottom, the top of the fermentatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com