Waste power lithium battery all-component cleaning and recycling method

A recycling method, lithium battery technology, applied in battery recycling, separation method, recycling of waste collectors, etc., can solve problems such as harsh process conditions and difficulty in large-scale industrial application, and achieve wide trial range, huge economic benefits and social benefits Benefits, the effect of realizing zero discharge of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

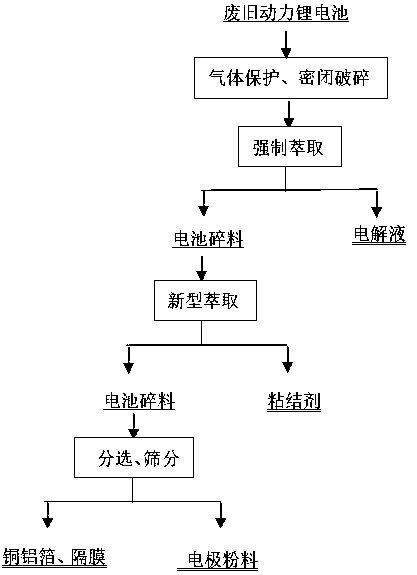

Image

Examples

Embodiment 1

[0021] (1) The steps of charged crushing of waste batteries under the protection of inert gas and closed atmosphere: 3 kg of waste power ternary lithium batteries are charged and crushed under the protection of carbon dioxide gas and closed atmosphere. The crushing process adopts primary crushing to obtain waste battery scraps, and the crushed battery scraps are transported to the ultrasonic enhanced extraction process by a closed system.

[0022] (2) The step of extracting and recovering the electrolyte by forced extraction method: the broken battery scraps enter the ultrasonic enhanced extraction process, the extraction temperature is 20°C, the extraction time: 60min, and the extraction flow rate: 1:2, so that the electrolysis of the battery scraps Liquid extraction enters the extractant, and through distillation and condensation, the electrolyte is efficiently separated and recovered.

[0023] (3) The step of extracting and recovering the binder by using a new extraction me...

Embodiment 2

[0027] (1) Steps of charged crushing of waste batteries under inert gas protection and airtight atmosphere: 10kg of waste power ternary lithium batteries are charged and crushed under nitrogen protection and airtight atmosphere. The crushing process adopts primary crushing to obtain waste battery scraps, and the crushed battery scraps are transported to the ultrasonic enhanced extraction process by a closed system.

[0028] (3) The step of extracting and recovering the electrolyte by forced extraction method: the battery fragments obtained by crushing enter the ultrasonic enhanced extraction process, the extraction temperature is 22°C, and the extraction time is 10 minutes: the extraction flow rate: 1:5, so that the electrolysis of the battery fragments Liquid extraction enters the extractant, and through distillation and condensation, the electrolyte is efficiently separated and recovered.

[0029](3) The step of extracting and recovering the binder by using a new extraction ...

Embodiment 3

[0033] (1) Steps of charged crushing of waste batteries under inert gas protection and closed atmosphere: 30kg of waste power ternary lithium batteries are charged and crushed under argon protection and closed atmosphere. The crushing process adopts primary crushing to obtain waste battery scraps, and the crushed battery scraps are transported to the ultrasonic enhanced extraction process by a closed system.

[0034] (4) The step of extracting and recovering the electrolyte by forced extraction method: the crushed battery scraps enter the ultrasonic enhanced extraction process, the extraction temperature is 25°C, the extraction time: 120min, and the extraction flow rate: 1:1, so that the electrolysis of the battery scraps Liquid extraction enters the extractant, and through distillation and condensation, the electrolyte is efficiently separated and recovered.

[0035] (3) The step of extracting and recovering the binder by using a new extraction method: the battery debris afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com