Loudspeaker cone and preparation method and application thereof

A loudspeaker and paper cone technology, applied in the field of loudspeakers, can solve the problems of destroying the film-forming continuity of other paper additives, affecting the sound quality of the loudspeaker, and reducing the mechanical properties of the paper cone, etc. The effect of surface free energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

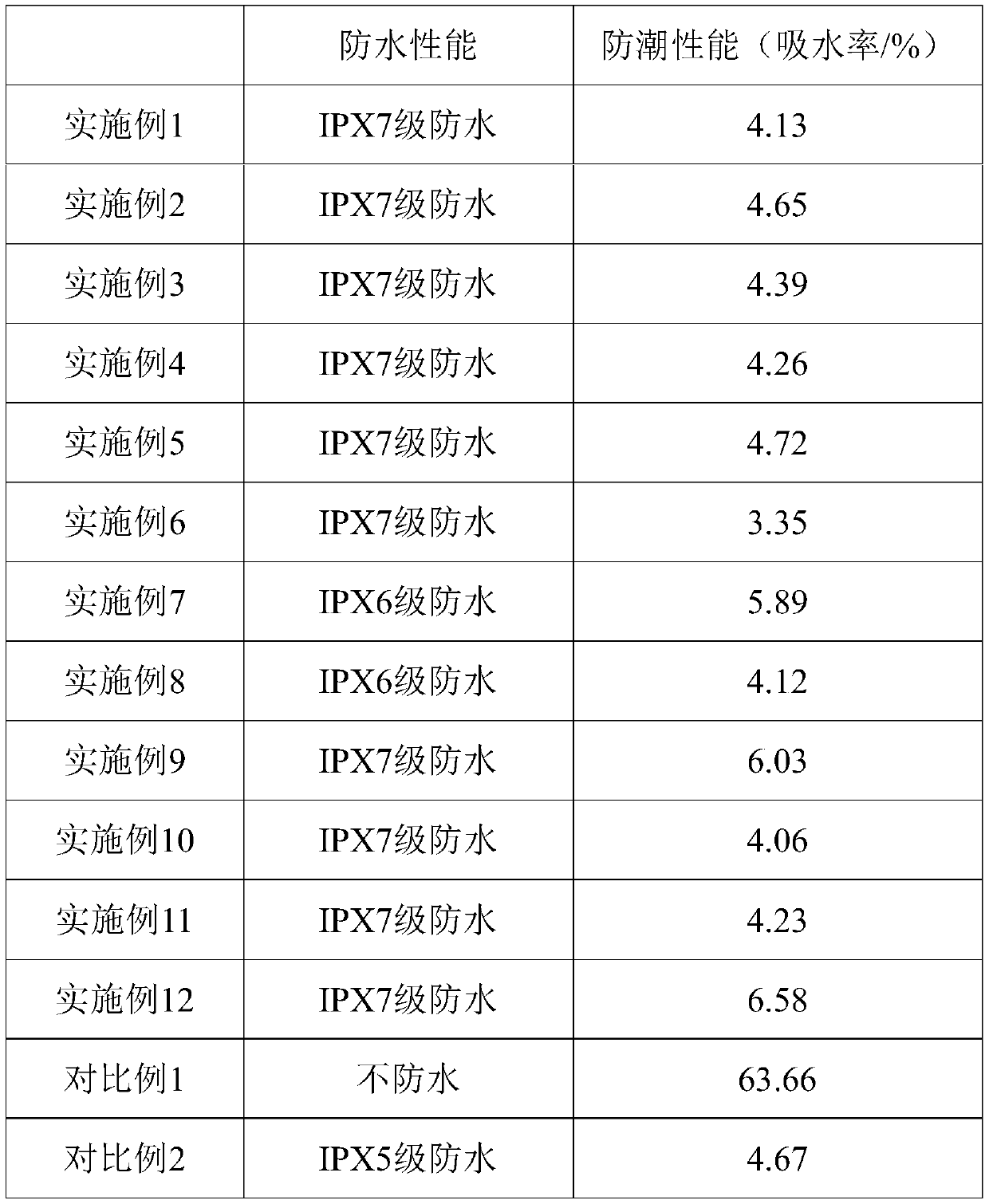

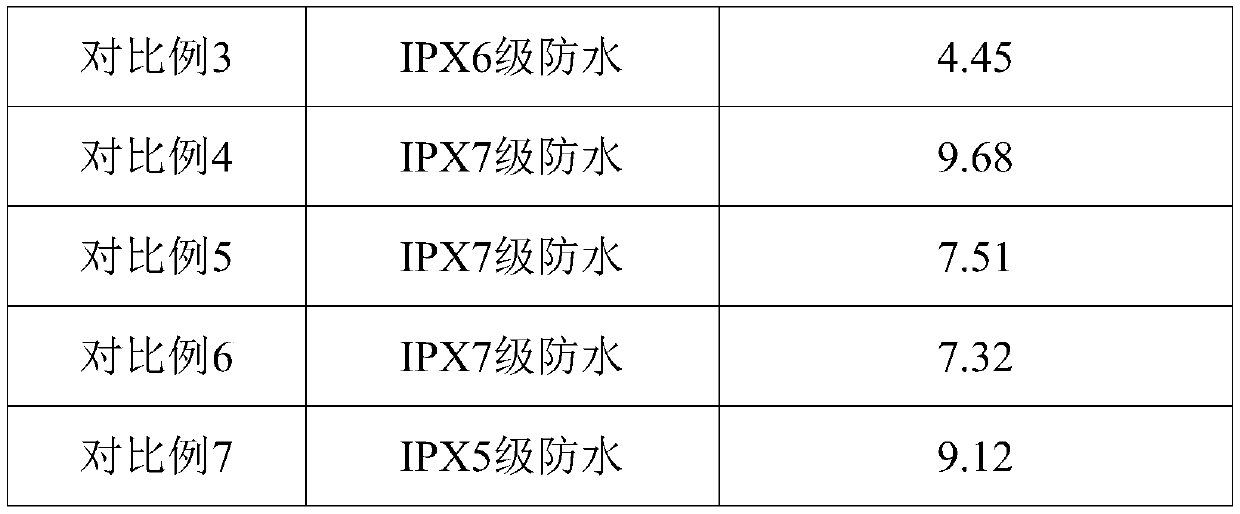

Examples

Embodiment 1

[0049] This embodiment provides a speaker cone, the preparation method is as follows:

[0050] (1) Add cationic styrene-acrylic emulsion in paper pulp, the addition is 10% of the absolute dry pulp quality, stir; Continue to add emulsified paraffin in the slurry after 15min, the addition is 2% of the absolute dry pulp quality, stir evenly, Obtain prefabricated slurry;

[0051] (2) The prefabricated slurry obtained in step (1) is scooped out, hot-pressed, and punched to obtain the speaker cone.

Embodiment 2

[0053] This embodiment provides a speaker cone, the preparation method is as follows:

[0054] (1) Add cationic styrene-acrylic emulsion in paper pulp, the addition is 5% of dry pulp quality, stir; Continue to add emulsified paraffin in pulp after 15min, the addition is 5% of dry pulp quality, stir evenly, Obtain prefabricated slurry;

[0055] (2) The prefabricated slurry obtained in step (1) is scooped out, hot-pressed, and punched to obtain the speaker cone.

Embodiment 3

[0057] This embodiment provides a speaker cone, the preparation method is as follows:

[0058] (1) Add cationic styrene-acrylic emulsion in paper pulp, the addition is 7.5% of the absolute dry pulp quality, stir; Continue to add emulsified paraffin in the slurry after 15min, the addition is 3% of the absolute dry pulp quality, stir evenly, Obtain prefabricated slurry;

[0059] (2) The prefabricated slurry obtained in step (1) is scooped out, hot-pressed, and punched to obtain the speaker cone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com