Preparation method of porous starch-metal organic framework composite material

A metal organic framework, porous starch technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve problems such as limited application, achieve fast adsorption rate, low cost, strong sulfonamide adsorption effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of raw materials

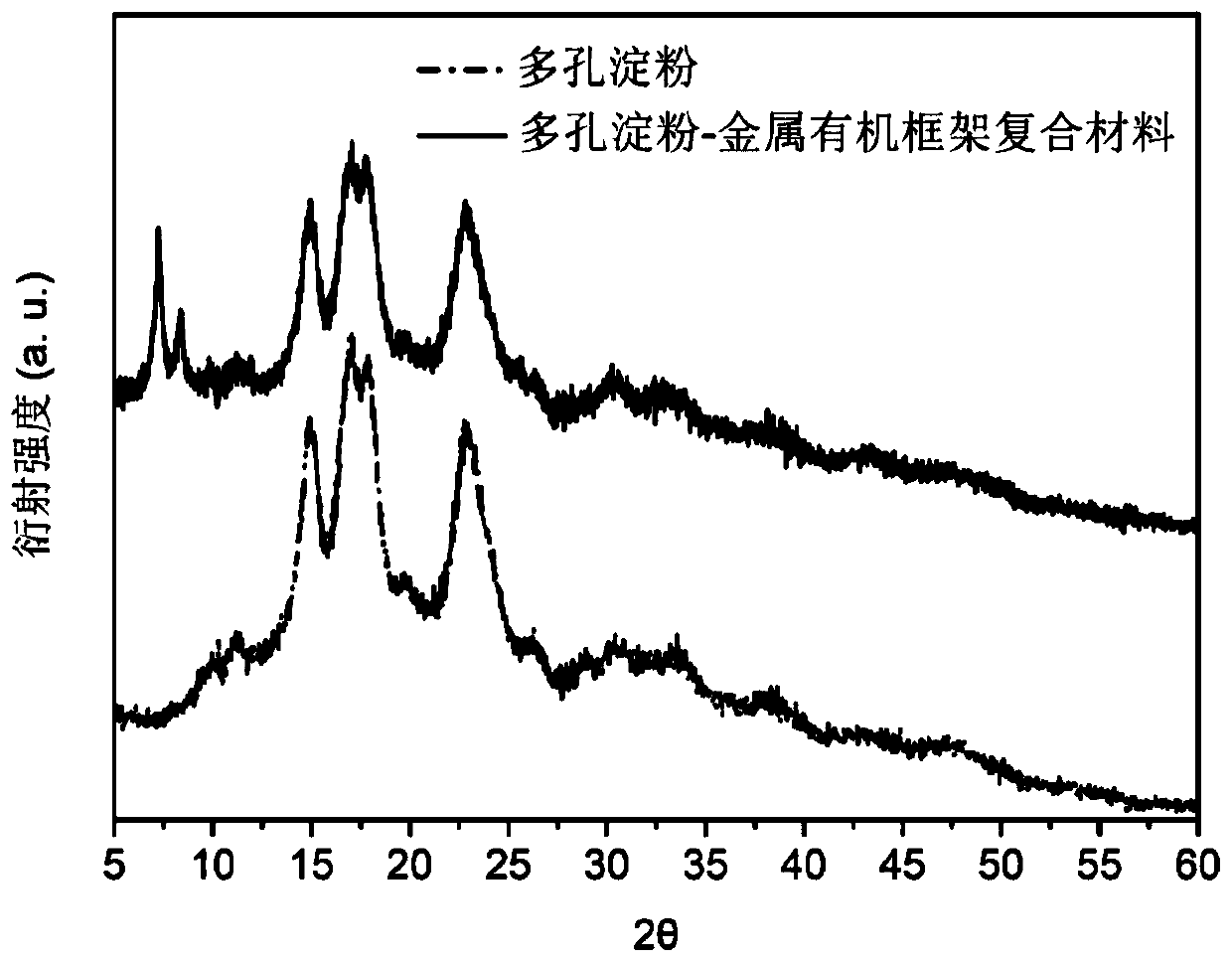

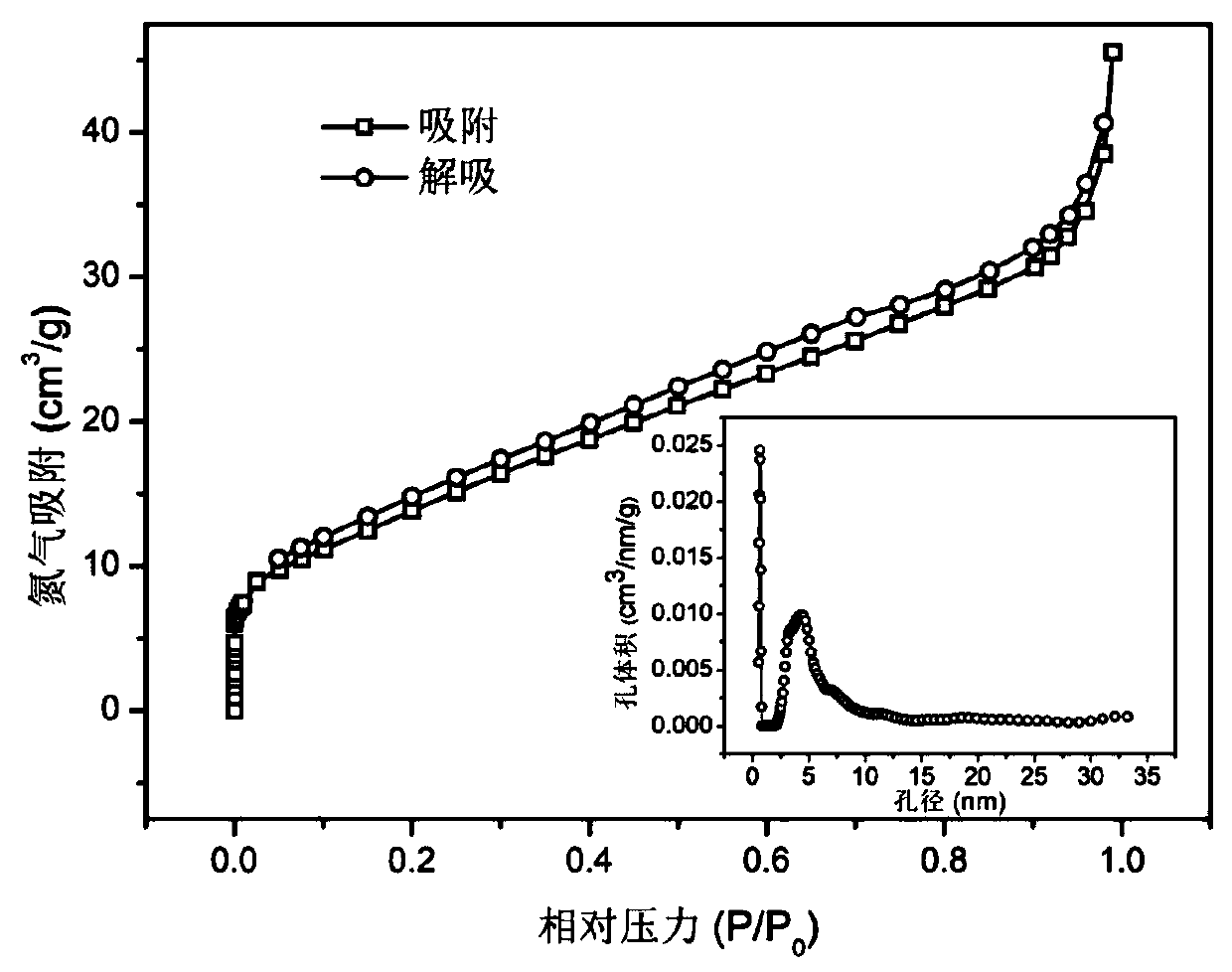

[0040]a) Preparation of porous starch: Disperse 10 g of corn starch in citric acid buffer (50 mL) at pH 5.0, add 0.10 mL of α-amylase and glucoamylase compound enzyme (1:3, v / v) at 50 ° C React for 5 hours, inactivate the enzyme, dry, and pass through a 100-mesh sieve to prepare porous starch.

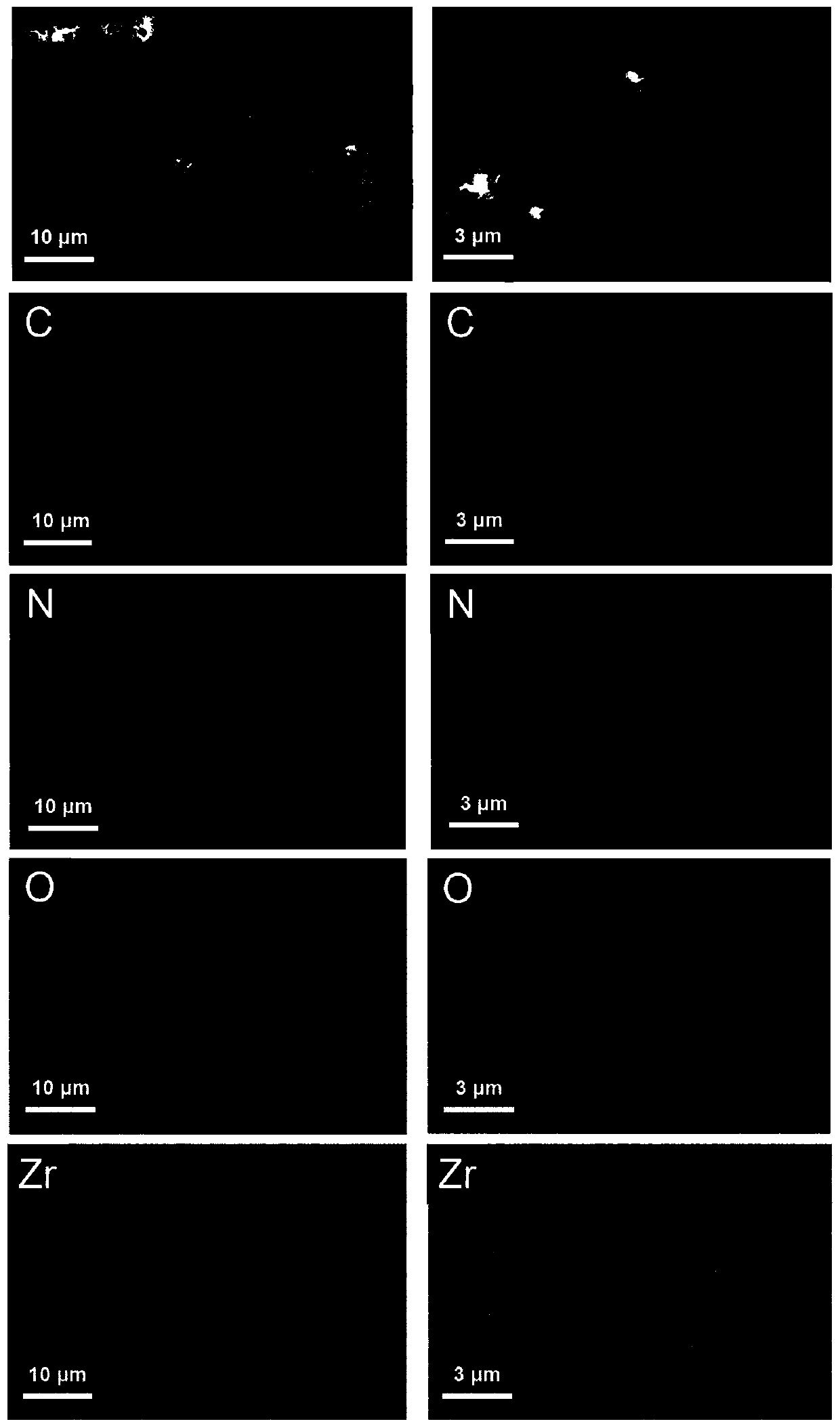

[0041] b) Synthesis of metal-organic framework materials: 4.8 g of zirconium chloride and 4.4 g of phthalic acid were dispersed in 100 mL of deionized water, and treated at 100° C. for 24 h using the reflux method. The sample obtained after reflux was further washed with deionized water, and 80 mL of deionized water was added to reflux for a second time for 16 h. The sample is centrifuged, freeze-dried, and pulverized to obtain the metal-organic framework material.

[0042] (2) Immobilization of porous starch-metal organic framework composites

[0043] a) Electrostatic adsorption: First, 0.2g of low-viscosity chitosan was heated and dissolve...

Embodiment 2

[0055] (1) Preparation of raw materials

[0056] a) Preparation of porous starch: Disperse 12 g of corn starch in citric acid buffer (60 mL) at pH 5.0, add 0.15 mL of α-amylase and glucoamylase complex enzyme (1:2, v / v) at 55 ° C React for 6 hours, inactivate the enzyme, dry, and pass through a 100-mesh sieve to prepare porous starch.

[0057] b) Synthesis of metal-organic framework materials: 2.4 g of zirconium chloride and 2.2 g of phthalic acid were dispersed in 50 mL of deionized water, and treated at 110° C. for 20 h using the reflux method. The sample obtained after reflux was further washed with deionized water, and 90 mL of deionized water was added to reflux for a second time for 15 h. The sample is centrifuged, freeze-dried, and pulverized to obtain the metal-organic framework material.

[0058] (2) Immobilization of porous starch-metal organic framework composites

[0059] a) Electrostatic adsorption: First, 0.3g of low-viscosity chitosan was dissolved by heating...

Embodiment 3

[0065] (1) Preparation of raw materials

[0066] a) Preparation of porous starch: Disperse 9 g of corn starch in citrate buffer (55 mL) at pH 5.2, add 0.10 mL of α-amylase and glucoamylase complex enzyme (1:3, v / v) at 55 ° C React for 5 hours, inactivate the enzyme, dry, and pass through an 80-mesh sieve to prepare porous starch.

[0067] b) Synthesis of metal-organic framework materials: 4.8 g of zirconium chloride and 4.4 g of phthalic acid were dispersed in 100 mL of deionized water, and treated at 95° C. for 30 h using the reflux method. The sample obtained after reflux was further washed with deionized water, and 80 mL of deionized water was added to reflux for a second time for 20 h. The sample is centrifuged, freeze-dried, and pulverized to obtain the metal-organic framework material.

[0068] (2) Immobilization of porous starch-metal organic framework composites

[0069] a) Electrostatic adsorption: First, 0.1 g of low viscosity was dissolved by heating with 0.01 mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

| load ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com