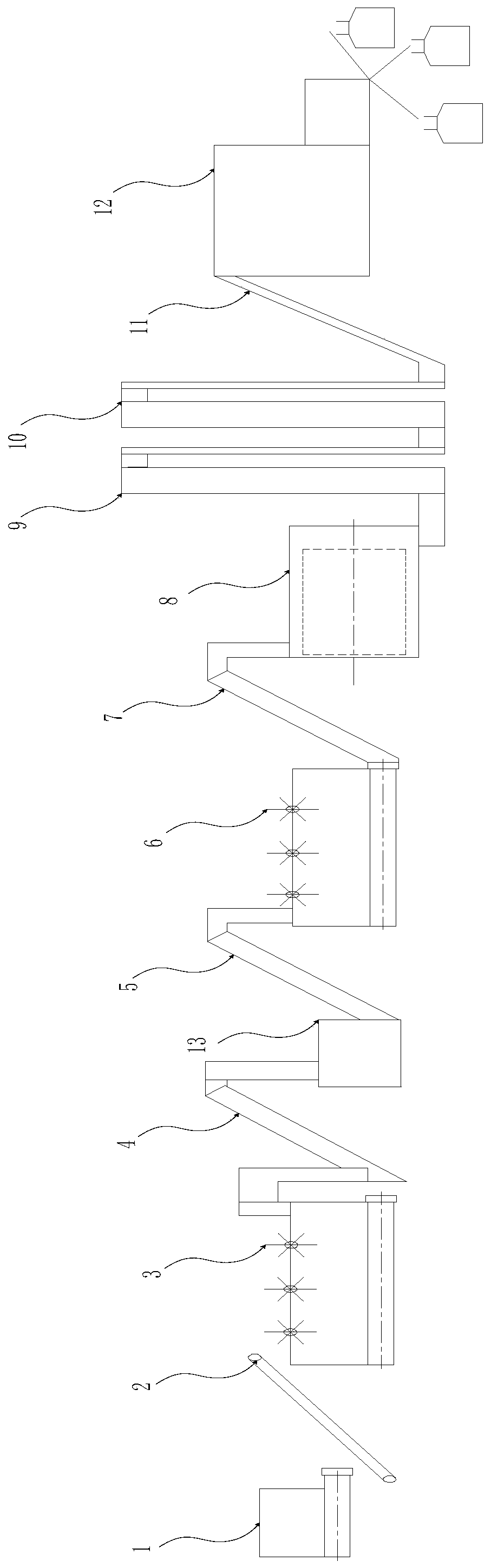

ABS plastic recycling and cleaning re-production production line

A technology for recycling ABS plastics and plastics, applied in plastic recycling, mechanical material recycling, recycling technology, etc., can solve problems such as increased production costs, increased workload, and poor dehydration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

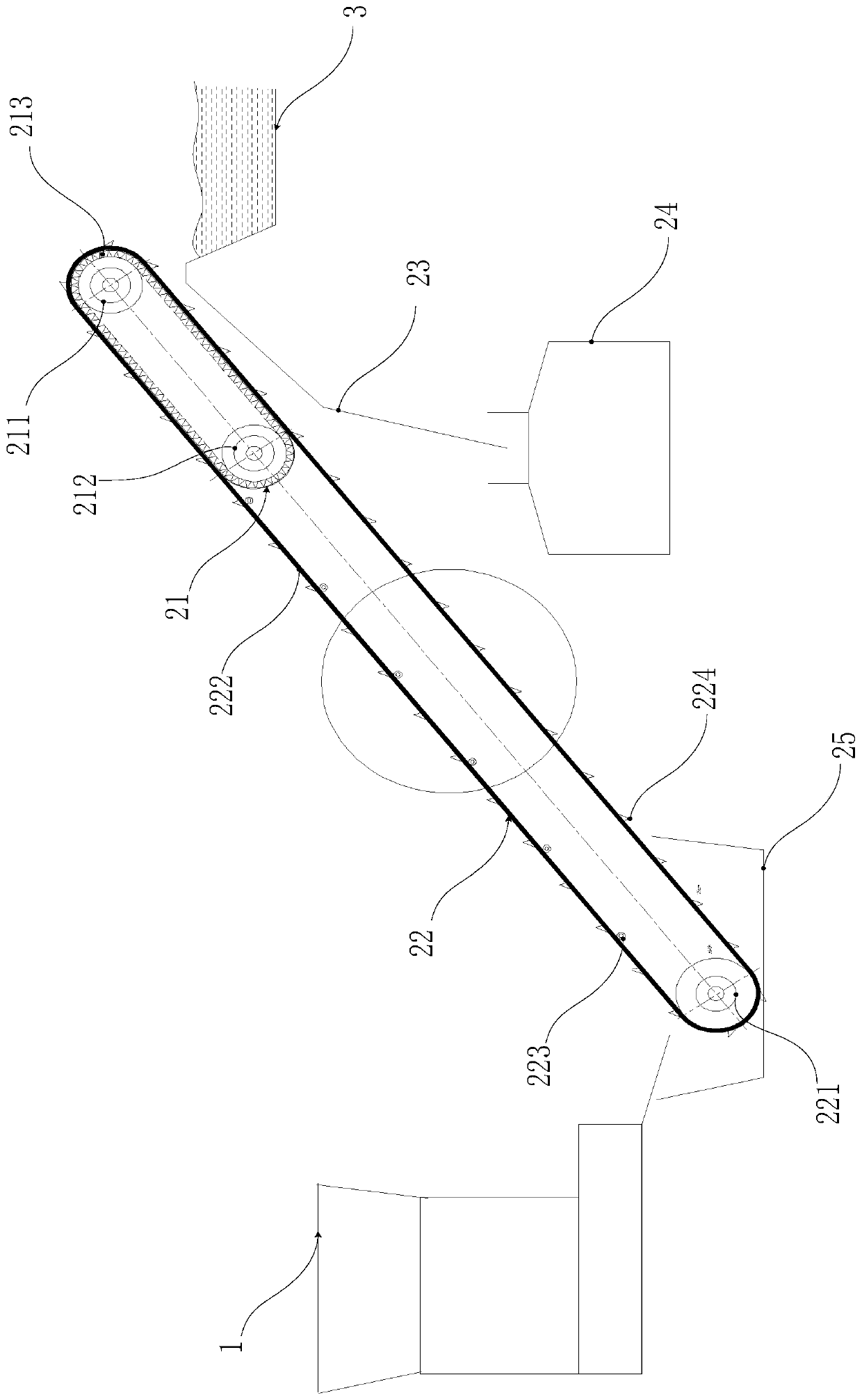

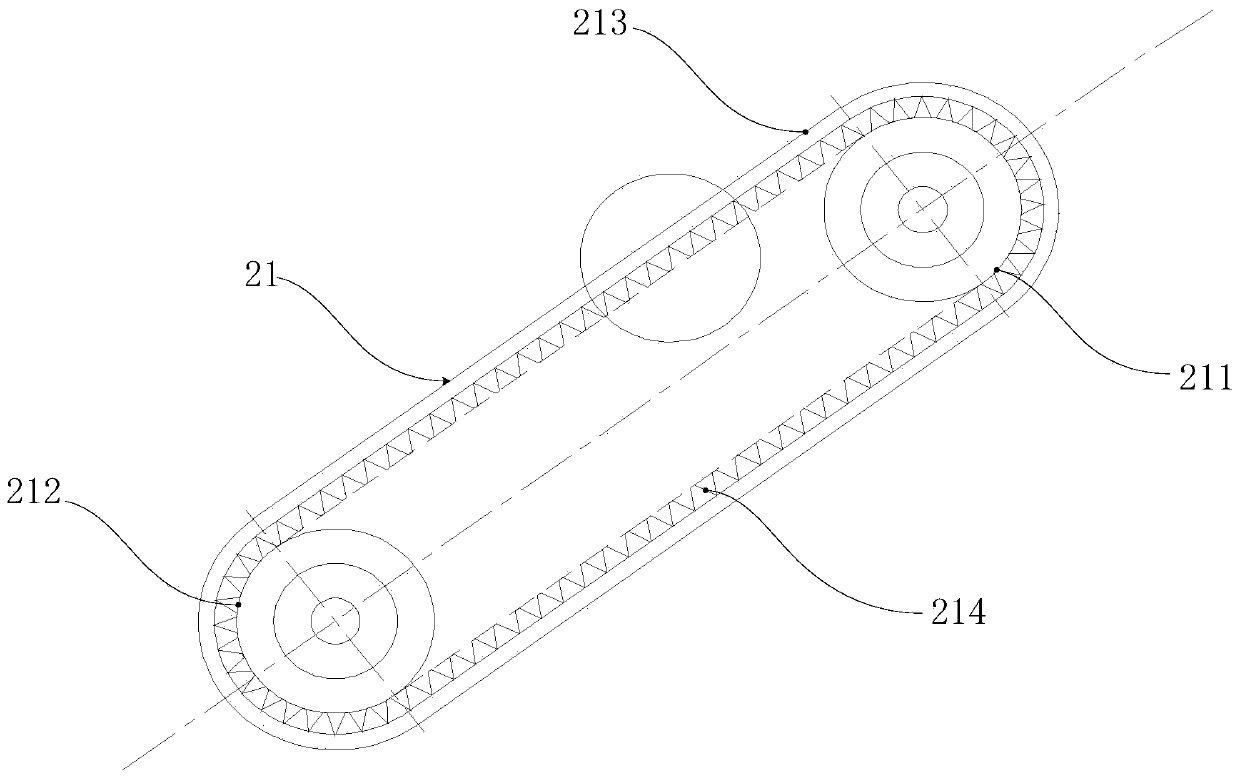

[0051] Such as Figure 2-5 Shown is the magnetic separation device 2 of the present invention, comprising a magnetic separation conveyor belt main body, a magnetic material slideway 23, a magnetic material collection box 24 and a collection tank 25, and the magnetic separation conveyor belt main body includes a magnetic transmission section 21 and a nonmagnetic transmission section 22. In order to better separate the magnetic substances, the main body of the magnetic separation conveyor belt is inclined with a low front end and a high rear end.

[0052]The magnetic transmission section 21 is positioned at the rear end of the magnetic separation conveyor belt main body and shares the same central axis with the magnetic separation conveyor belt main body. The magnetic transmission section 21 includes a drive mounted on an external frame (the frame is a conventional component, not shown in the figure). Roller 211 and first driven roller 212, described driving roller 211 and first...

Embodiment 2

[0057] Such as Figure 6-10 Shown is the first dehydration conveying mechanism 4 of the present invention, comprising a feed pipeline 41, a lifting mechanism and a water receiving tank 46; Filter plate 45 and lifting screw 47.

[0058] The feed pipe 41 is designed in an "L" shape. Such a design can effectively prevent the materials and part of the cleaning fluid from splashing when they fall, and can better gather the materials at the bottom of the lifting mechanism, which can be more thorough. Lift and convey the material efficiently to avoid material loss.

[0059] The screw pipe 42 is designed in the shape of a truncated cone, communicates with the bottom of the feed pipe 41 , and its cross-sectional diameter decreases sequentially from bottom to top, and a discharge pipe 43 is arranged on the upper part of the lower side of the screw pipe 42 .

[0060] The lifting screw 47 is arranged in the inner cavity of the screw pipe 42, and includes a lifting screw shaft 471, a fir...

Embodiment 3

[0068] Such as Figure 11-13 Shown is the spray mechanism 13 of the present invention, including a water receiving mechanism 131, a collection chamber 132, a water pipe placement tank 133, a dehydration material pipe 134, a feed hopper 135, a spray installation seat 136, and a spray head 137.

[0069] The water receiving mechanism 131 is designed as a box with an open top, and three water baffles are provided on the left part of the water receiving mechanism 131 extending upward along its side wall.

[0070] Just above the right part of the water receiving mechanism 131 is fixedly provided with a collection chamber 132, and a water pipe placement groove 133 is formed between the water baffles on the front and rear sides of the water receiving mechanism 131 and the collection chamber 132, so that the external water pump will The water in the water receiving mechanism 131 is taken away.

[0071] Described collection chamber 132 is the box body design of opening below, and the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com