Automatic feeding and discharging device and feeding and discharging method for trays

An automatic loading and unloading and palletizing technology, which is applied in transportation and packaging, object stacking, object destacking, etc., can solve the problem of machine purchase, expensive maintenance costs, difficult to estimate enterprise maintenance costs, palletizers cannot material pallets, etc. problems, to achieve the effect of low manufacturing cost, saving production resources, and clear structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention discloses an automatic pallet loading and unloading device and a corresponding pallet automatic loading and unloading method, specifically as follows.

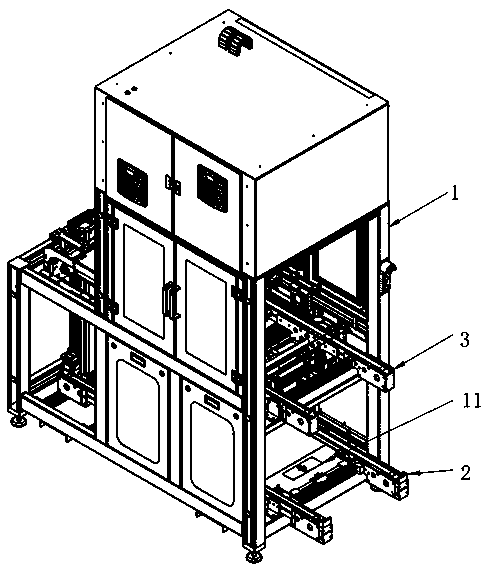

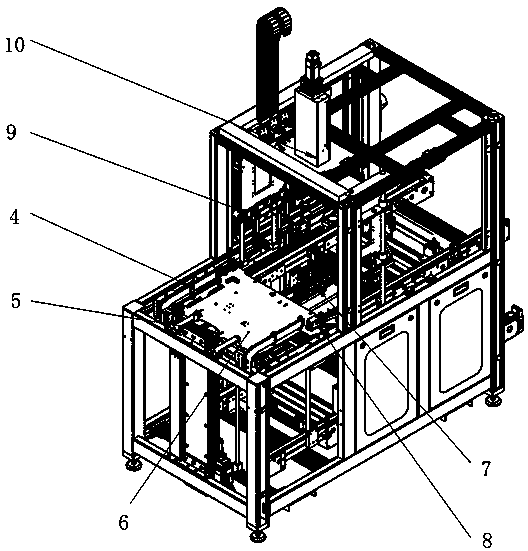

[0031] like Figure 1~Figure 2 As shown, a pallet automatic loading and unloading device is matched with the retrieving mechanism (not shown in the figure) set on the main platform of the production line, including a device frame 1 and various functional components arranged on the device frame 1 .

[0032] The functional components include a feeding component for conveying material trays into the device, a destacking component for destacking the material trays, and a positioning and auxiliary realization of the material trays after the destacking is completed. The transfer positioning assembly for taking out materials from the reclaiming mechanism, the stacking assembly for stacking the material trays that have been reclaimed, and the unloading assembly for sending the material trays out of the device, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com