A two-phase aqueous extraction method of bletilla striata glucomannan

A technique for Bletilla striata glucomannan and stilbene glucomannan, which is applied in the field of glucomannan extraction, can solve the problems of low extraction efficiency, long time consumption, impure extraction components and the like, and achieves a short extraction period and high extraction rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

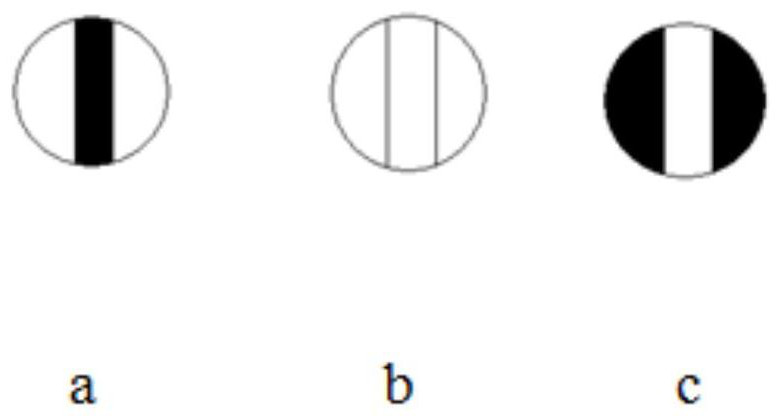

Image

Examples

Embodiment 1

[0033] A two-phase extraction method for bletilla striata glucomannan, comprising the following steps:

[0034] (1) After washing the bletilla striata, mix the bletilla striata with deionized water at a mass ratio of 1:4, put it in a homogenizer, and homogenize at 4°C, 13000rpm, for 5 minutes, with an interval of 1 minute, and the total homogenization time is 30 minutes , to prepare bletilla striata slurry;

[0035] (2) Centrifuge the Bletilla striata slurry in step (1) in a centrifuge at 4°C, 5000rpm, for 20min to obtain the supernatant;

[0036] (3) Establish an ethanol-dipotassium hydrogen phosphate two-phase system: the volume fraction of ethanol in the ethanol aqueous solution is 70%, the weight fraction of dipotassium hydrogen phosphate in the dipotassium hydrogen phosphate aqueous solution is 55%, and the ethanol aqueous solution and dipotassium hydrogen phosphate The volume ratio of the aqueous solution is 3:7; under the conditions of this volume ratio, it can not onl...

Embodiment 2

[0041] A two-phase extraction method for bletilla striata glucomannan, comprising the following steps:

[0042] (1) After washing the bletilla striata, mix the bletilla striata with deionized water at a mass ratio of 1:4, place it in a homogenizer, and homogenize at 6°C and 14,000rpm for 5 minutes, with an interval of 1 minute, and the total homogenization time is 25 minutes , to prepare bletilla striata slurry;

[0043] (2) Put the bletilla striata slurry in step (1) in a centrifuge, centrifuge at 6000 rpm for 15 minutes at 6°C to obtain the supernatant;

[0044] (3) Establish an ethanol-dipotassium hydrogen phosphate two-phase system: the volume fraction of ethanol in the ethanol aqueous solution is 70%, the weight fraction of dipotassium hydrogen phosphate in the dipotassium hydrogen phosphate aqueous solution is 55%, and the ethanol aqueous solution and dipotassium hydrogen phosphate The volume ratio of the aqueous solution is 3:7; under the conditions of this volume rati...

Embodiment 3

[0049] A two-phase extraction method for bletilla striata glucomannan, comprising the following steps:

[0050] (1) After washing the bletilla striata, mix the bletilla striata with deionized water at a mass ratio of 1:4, place it in a homogenizer, and homogenize at 10°C and 15,000rpm for 5 minutes, with an interval of 1 minute, and the total homogenization time is 25 minutes , to prepare bletilla striata slurry;

[0051] (2) Put the bletilla striata slurry in step (1) in a centrifuge, centrifuge at 10°C, 8000rpm, for 15min, and obtain the supernatant;

[0052] (3) Establish an ethanol-dipotassium hydrogen phosphate two-phase system: the volume fraction of ethanol in the ethanol aqueous solution is 70%, the weight fraction of dipotassium hydrogen phosphate in the dipotassium hydrogen phosphate aqueous solution is 55%, and the ethanol aqueous solution and dipotassium hydrogen phosphate The volume ratio of the aqueous solution is 3:7; under the conditions of this volume ratio, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com