Magnesium alloy passivation solution and magnesium alloy surface treatment method

A passivation treatment and surface treatment technology, which is applied in the direction of metal material coating process, superimposed layer plating, electrolytic coating, etc., can solve problems such as reaction, and achieve the effects of low energy consumption, low resistance, and corrosion prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In order to achieve the above object, the magnesium alloy passivation solution provided by the present invention is used for the passivation treatment before the magnesium alloy colorless electrophoresis. The magnesium alloy passivation solution uses water as a solvent and includes the following components calculated by concentration:

[0041] Chromium nitrate 2.5g / L;

[0042] Oxalic acid 0.8g / L;

[0043] Citric acid 1g / L;

[0044] Sodium silicate 1.5g / L;

[0045] Cobalt nitrate 1g / L.

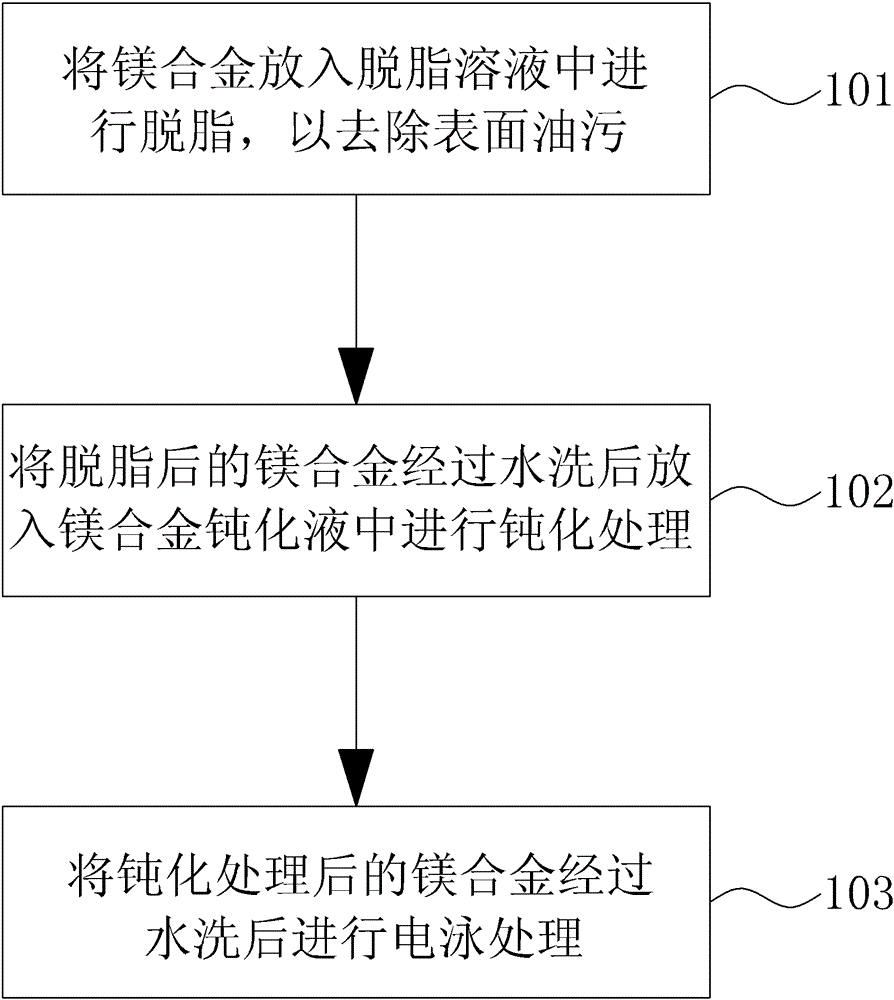

[0046] The present invention also provides a magnesium alloy surface treatment method, the magnesium alloy surface treatment method comprising the following steps:

[0047] Step 101: Degreasing the magnesium alloy in a degreasing solution to remove surface oil, where the concentration of the degreasing solution is 40 g / L, the degreasing temperature is 60° C., and the degreasing time is 10 minutes;

[0048] Step 102: Wash the degreased magnesium alloy with water and put it into the ma...

Embodiment 2

[0051] In order to achieve the above object, the magnesium alloy passivation solution provided by the present invention is used for the passivation treatment before the magnesium alloy colorless electrophoresis. The magnesium alloy passivation solution uses water as a solvent and includes the following components calculated by concentration:

[0052] Chromium nitrate 1.5g / L;

[0053] Oxalic acid 1.2g / L;

[0054] Citric acid 0.8g / L;

[0055] Sodium silicate 1.2g / L;

[0056] Cobalt nitrate 0.8g / L.

[0057] The present invention also provides a magnesium alloy surface treatment method, the magnesium alloy surface treatment method comprising the following steps:

[0058] Step 101: Degreasing the magnesium alloy in a degreasing solution to remove surface oil, where the concentration of the degreasing solution is 60 g / L, the degreasing temperature is 60° C., and the degreasing time is 10 minutes;

[0059] Step 102: Wash the degreased magnesium alloy with water and put it into th...

Embodiment 3

[0062] In order to achieve the above object, the magnesium alloy passivation solution provided by the present invention is used for the passivation treatment before the magnesium alloy colorless electrophoresis. The magnesium alloy passivation solution uses water as a solvent and includes the following components calculated by concentration:

[0063] Chromium nitrate 2g / L;

[0064] Oxalic acid 1g / L;

[0065] Citric acid 0.5g / L;

[0066] Sodium silicate 1g / L;

[0067] Cobalt nitrate 0.5g / L.

[0068] The present invention also provides a magnesium alloy surface treatment method, the magnesium alloy surface treatment method comprising the following steps:

[0069] Step 101: Degreasing the magnesium alloy in a degreasing solution to remove surface oil, where the concentration of the degreasing solution is 50 g / L, the degreasing temperature is 60° C., and the degreasing time is 10 minutes;

[0070] Step 102: Wash the degreased magnesium alloy with water and put it into the magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com