Method for preparing stimuli-responsive porous aquagel

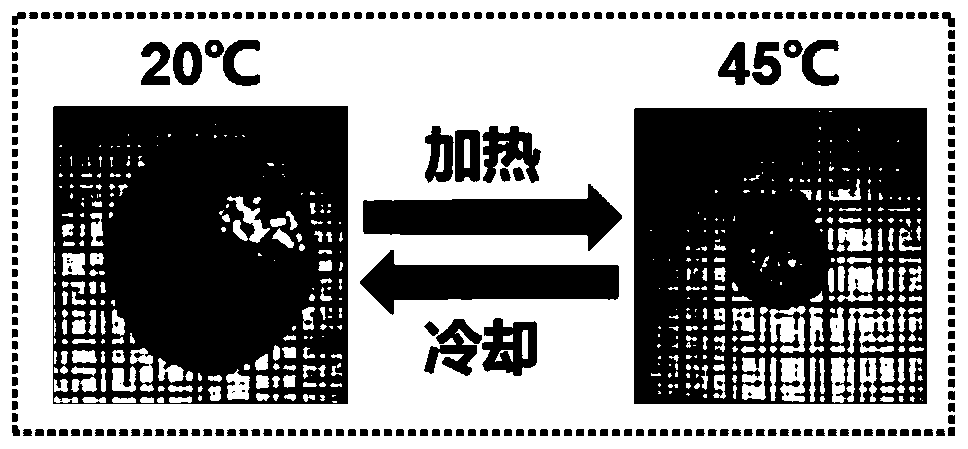

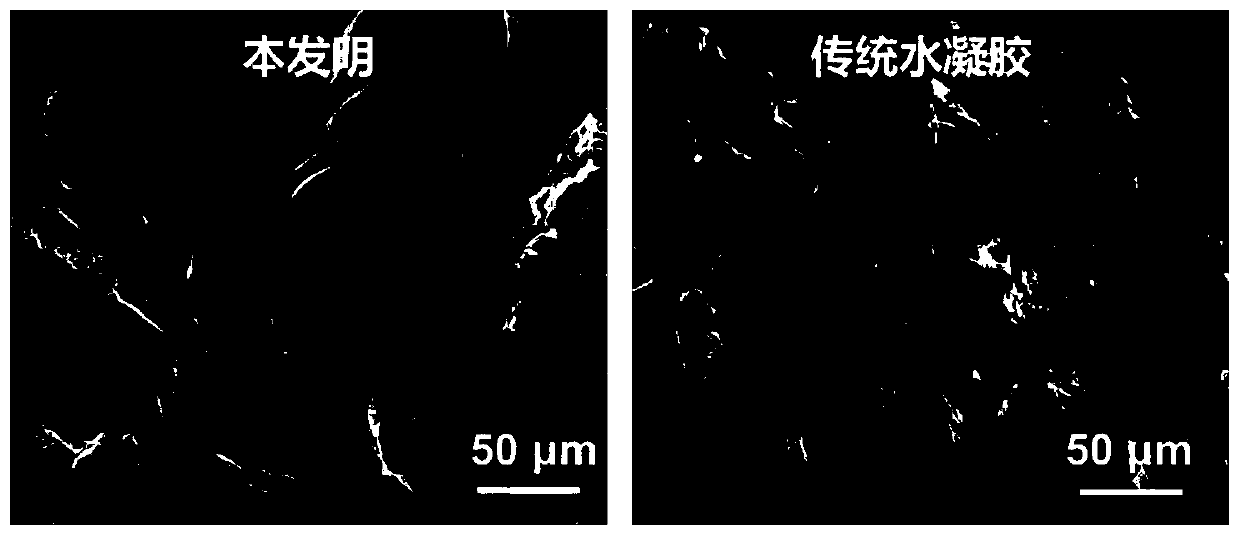

A porous hydrogel and stimuli-responsive technology, which is applied in the field of preparation of stimuli-responsive porous hydrogels, can solve the problems of slow thermal response speed and long time consumption, and achieves improved elasticity and fatigue resistance, improved response speed and Swelling ratio, effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

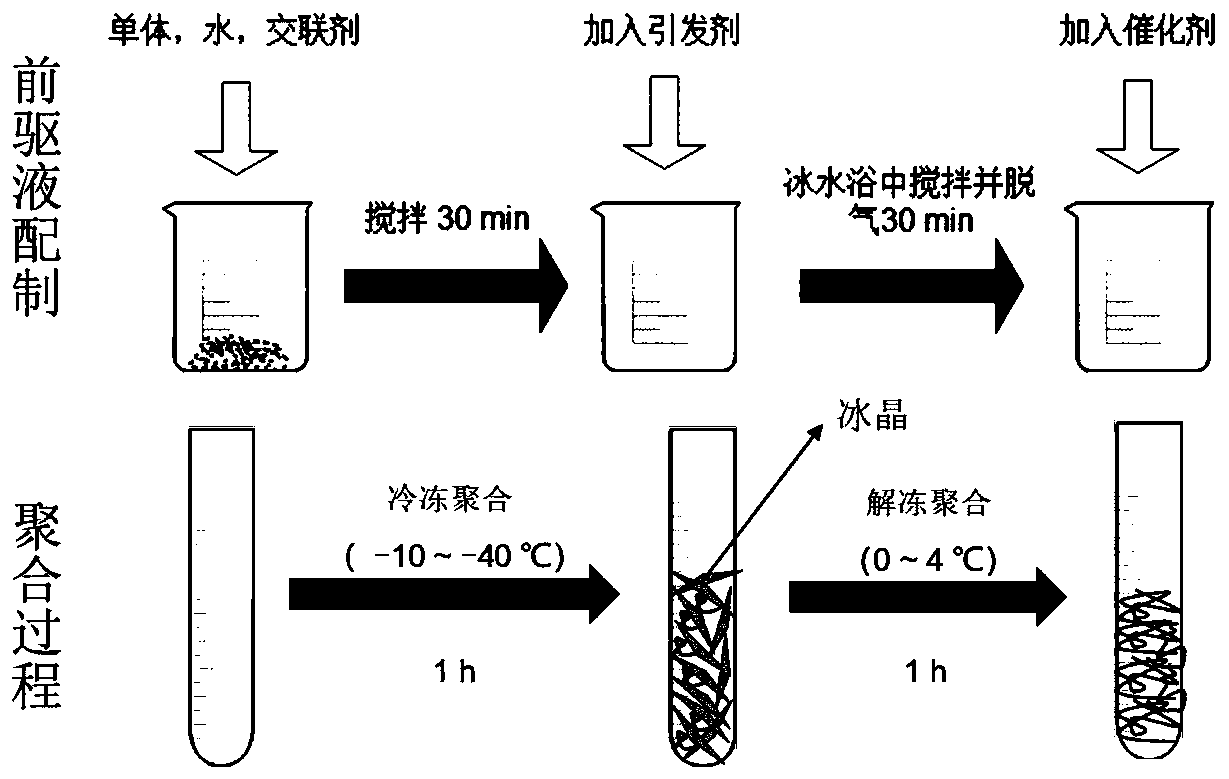

[0025] Such as figure 1 Shown, the present invention provides a kind of preparation method of stimuli-responsive porous hydrogel, comprising the following steps:

[0026] Step 1. Mix polymer monomer, initiator, crosslinking agent and water according to the mass ratio of (500~2000):(2~5):(1~10):5000 at 0~4°C to obtain Precursor;

[0027] In some typical examples, N-isopropylacrylamide, N,N-methylenebisacrylamide and ammonium persulfate are dissolved in 5 mL of deionized aqueous solution at a mass ratio of 500:1:10, and placed in an ice-water bath Use a magnetic stirrer to stir for 2 hours to obtain a homogeneous aqueous solution, then place the mixture under nitrogen protection, rinse for 30 minutes, remove dissolved oxygen, and finally add 10 μL of tetramethylethylenediamine under vigorous stirring, and store in a nitrogen-protected ice Stir in a water bath for 10 min to obtain a precursor mixed solution.

[0028] Step 2. Place the obtained precursor liquid at -10 to -40°C ...

Embodiment 1

[0035] Dissolve 0.5 g of N-isopropylacrylamide, 1 mg of N,N-methylenebisacrylamide, and 10 mg of ammonium persulfate in 5 mL of deionized water, and stir for 2 hours in an ice-water bath using a magnetic stirrer to obtain a homogeneous aqueous solution , and then the mixture was placed under nitrogen protection, rinsed for 30 min to remove dissolved oxygen, and finally 10 μL of tetramethylethylenediamine was added under vigorous stirring, and stirred in an ice-water bath under nitrogen protection for 10 min to obtain a precursor mixed solution. The obtained mixed solution was quickly placed in a centrifuge tube, and placed in a refrigerator at -20°C for freezing and polymerization for 2 hours to obtain a cryogel. The cryogel was thawed and polymerized in a refrigerator at 4° C. for 2 hours to obtain the high-performance hydrogel. The swelling ratio of the hydrogel is 41, the deswelling rate is 20s, the swelling rate is 30s, and the compressive strain is 80%.

Embodiment 2

[0037]Dissolve 0.5 g of N-isopropylacrylamide, 1 mg of N,N-methylenebisacrylamide, and 10 mg of ammonium persulfate in 5 mL of deionized water, and stir for 2 hours in an ice-water bath using a magnetic stirrer to obtain a homogeneous aqueous solution , and then the mixture was placed under nitrogen protection, rinsed for 30 min to remove dissolved oxygen, and finally 10 μL of tetramethylethylenediamine was added under vigorous stirring, and stirred in an ice-water bath under nitrogen protection for 10 min to obtain a precursor mixed solution. The obtained mixed solution was quickly placed in a centrifuge tube, and placed in a refrigerator at -20°C for freezing polymerization for 9 hours to obtain a cryogel. The cryogel was thawed and polymerized in a refrigerator at 4° C. for 9 hours to obtain the high-performance hydrogel. The swelling ratio of the hydrogel is 37.6, the deswelling rate is 20s, the swelling rate is 30s, and the compressive strain is 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com