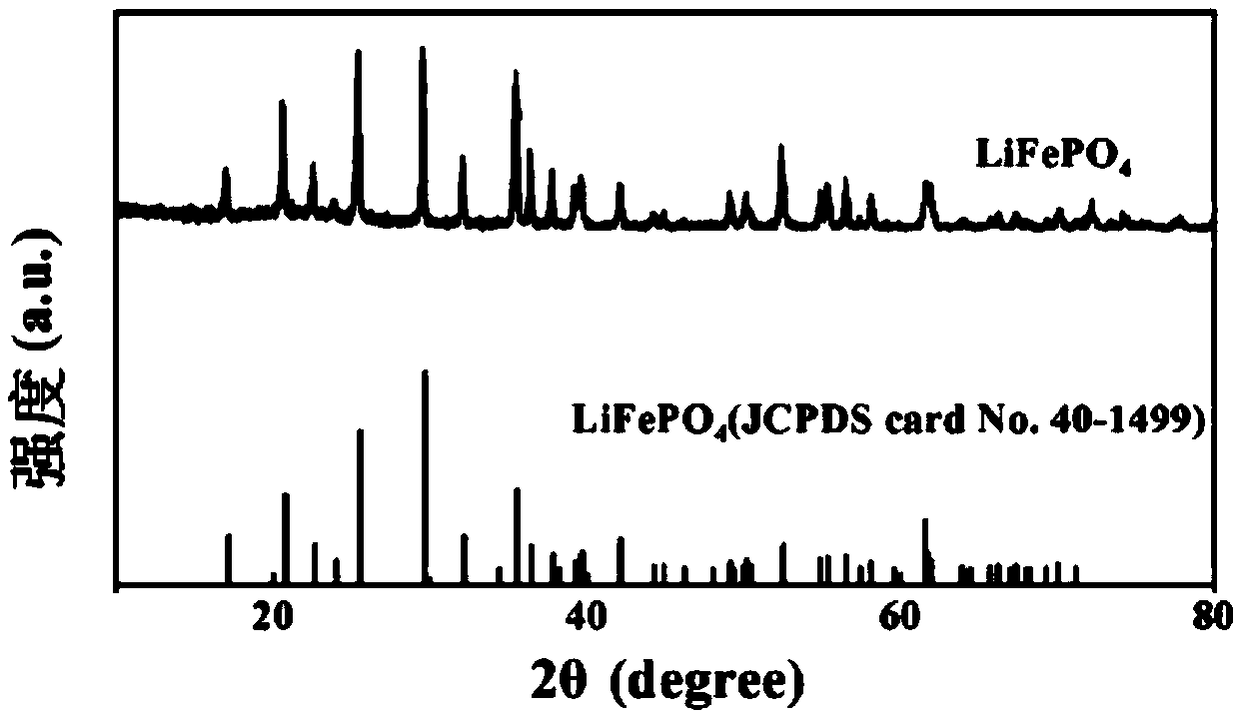

Porous lithium ion battery positive electrode material and preparation method and application thereof

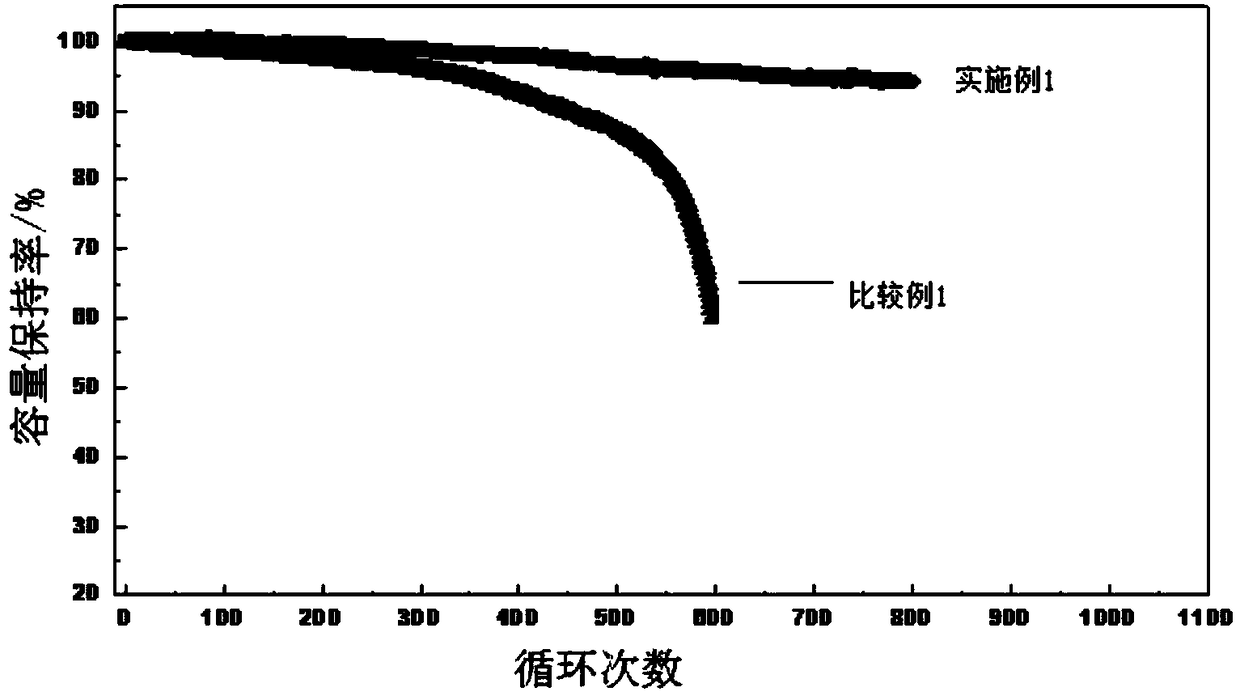

A technology of lithium ion battery and positive electrode material, applied in the field of positive electrode material of porous lithium ion battery and its preparation, can solve the problems of uneven particle size of lithium iron phosphate material, affecting lithium ion diffusion rate and conductivity, affecting battery performance, etc. The compacted density is unaffected, suitable for industrial production, and the preparation method is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

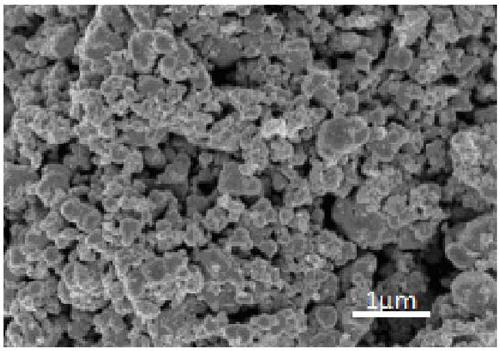

[0031] A preparation method for a porous lithium-ion battery cathode material, comprising the following steps:

[0032] S1. Dissolving ferrous phosphate octahydrate and lithium hydroxide in deionized water, adding sodium dodecylbenzenesulfonate and oxalic acid thereto, and adjusting the pH to 4.8 to obtain a mixed precursor solution; the phosphoric acid octahydrate The ratio of the amount of ferrous iron to lithium hydroxide is 1:1.0; the concentration of the ferrous phosphate in deionized water is 0.25mol / L; the final concentration of the additive in the mixed precursor solution is 5.3mg / L L; The final concentration of the surfactant in the mixed precursor solution is 5.2mg / L;

[0033] S2. Under the protection of nitrogen, hydrogen and mixed gas, the mixed precursor solution is calcined at 682° C. for 12 hours at a volume ratio of nitrogen to hydrogen of 92:8. After cooling, it is pulverized to a particle size of 80-120 mesh ; The porous lithium iron phosphate porous lithium...

Embodiment 2

[0043] A preparation method for a porous lithium-ion battery cathode material, comprising the following steps:

[0044] S1, dissolving ferrous phosphate tetrahydrate and lithium carbonate in deionized water, and adding sodium dodecylsulfonate and ammonium bicarbonate to it, adjusting the pH to 5.0 to obtain a mixed precursor solution; the ferrous phosphate With the ratio of the amount of substance of lithium carbonate 1:1.2; The concentration of the ferrous phosphate tetrahydrate in deionized water is 0.5mol / L; The final concentration of the additive in the mixed precursor solution is 8.5mg / L; The final concentration of the surfactant in the mixed precursor solution is 6.7mg / L;

[0045] S2. Under the protection of nitrogen, hydrogen and mixed gas, the mixed precursor solution is calcined at 700°C for 10 hours at a volume ratio of nitrogen to hydrogen of 95:5, and after cooling, it is crushed to a particle size of 80-120 mesh ; The porous lithium iron phosphate porous lithium ...

Embodiment 3

[0047] A preparation method for a porous lithium-ion battery cathode material, comprising the following steps:

[0048] S1, dissolving ferrous phosphate octahydrate and lithium dihydrogen phosphate in deionized water, and adding surfactants and additives thereto to adjust the pH to 4.5 to obtain a mixed precursor solution; the ferrous phosphate and lithium source The ratio of the amount of substance is 1:1.2; the concentration of the ferrous phosphate in deionized water is 0.38mol / L; the final concentration of the additive in the mixed precursor solution is 5mg / L; the surfactant is in The final concentration in the mixed precursor solution is 3.3mg / L;

[0049]S2. Under the protection of nitrogen, hydrogen and mixed gas, the mixed precursor solution is calcined at 660° C. for 14 hours at a volume ratio of nitrogen to hydrogen of 94:6. After cooling, it is crushed to a particle size of 80-120 mesh ; The porous lithium iron phosphate porous lithium ion battery cathode material c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com