A kind of composite floc and its preparation method and application

A flake and polymer technology, applied in melt spinning, textile and papermaking, spinneret assemblies, etc., can solve the problems of poor flame retardancy, poor thermal insulation performance, poor sound absorption effect, etc., and achieve excellent rebound The effect of rate and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] [Preparation method of composite flakes]

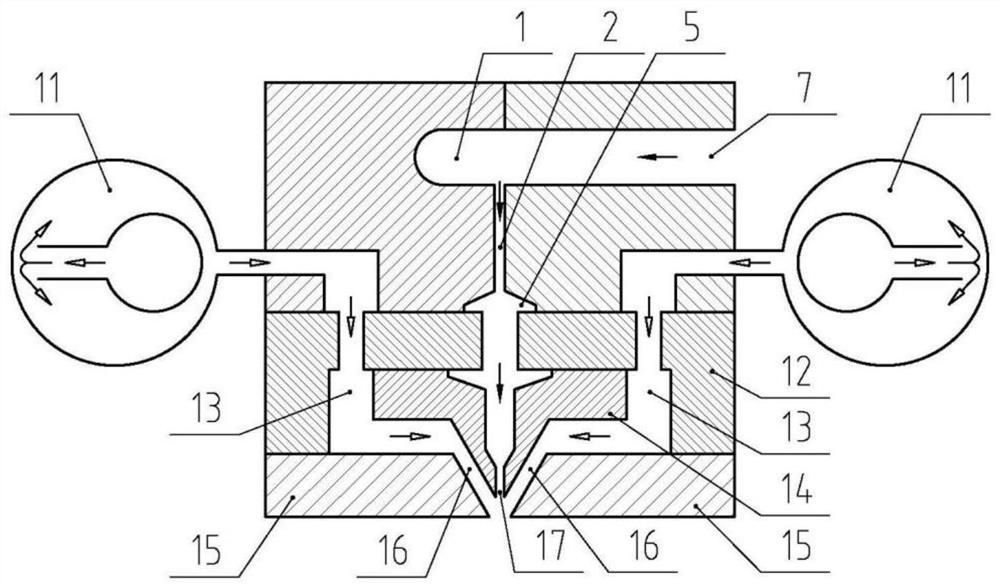

[0068] As mentioned above, the present invention provides a method for preparing composite wadding, the composite wadding includes a melt-blown fiber layer, and the melt-blown fiber layer includes melt-blown fibers and short fibers; the average of the melt-blown fibers The diameter is 200-2000 nanometers, and the mass percentage content of the melt-blown fiber in the diameter range is greater than or equal to 80%; the method is based on a melt-blown device; the melt-blown device includes a hanger-shaped spinning die, Spin packs, air knives and devices for uniform fluid distribution;

[0069] The spinning assembly includes a distribution plate and a spinneret; the spinneret forms spinneret holes for melt ejection; the spinneret, distribution plate and air knife form a draft hot air flow channel for heat Air circulation; the air knife and spinneret form an air gap slit for accelerating hot air and ejecting it;

[0070] The bala...

Embodiment 1

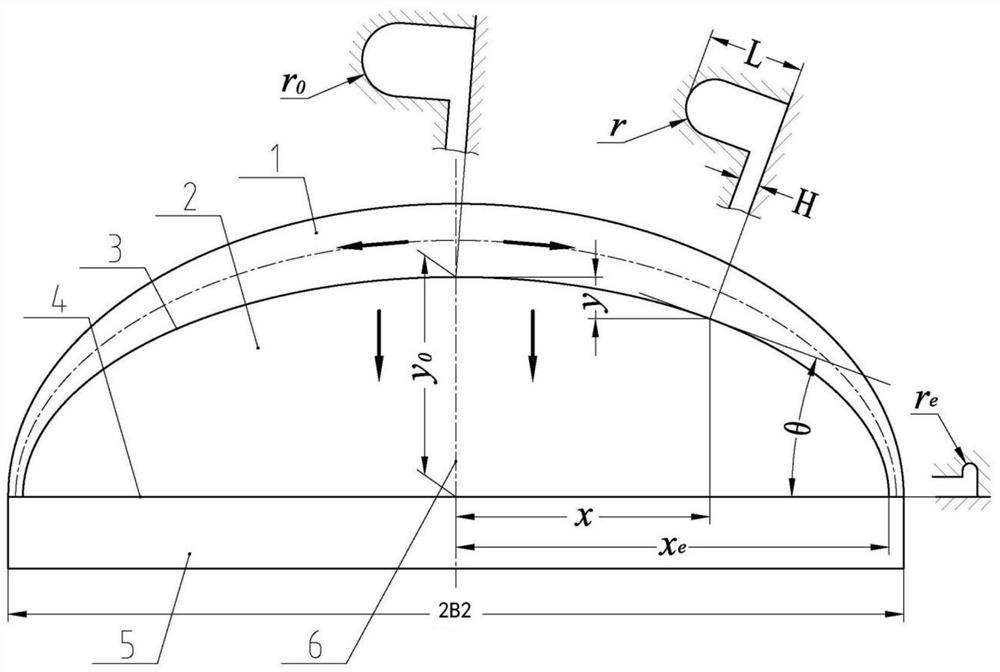

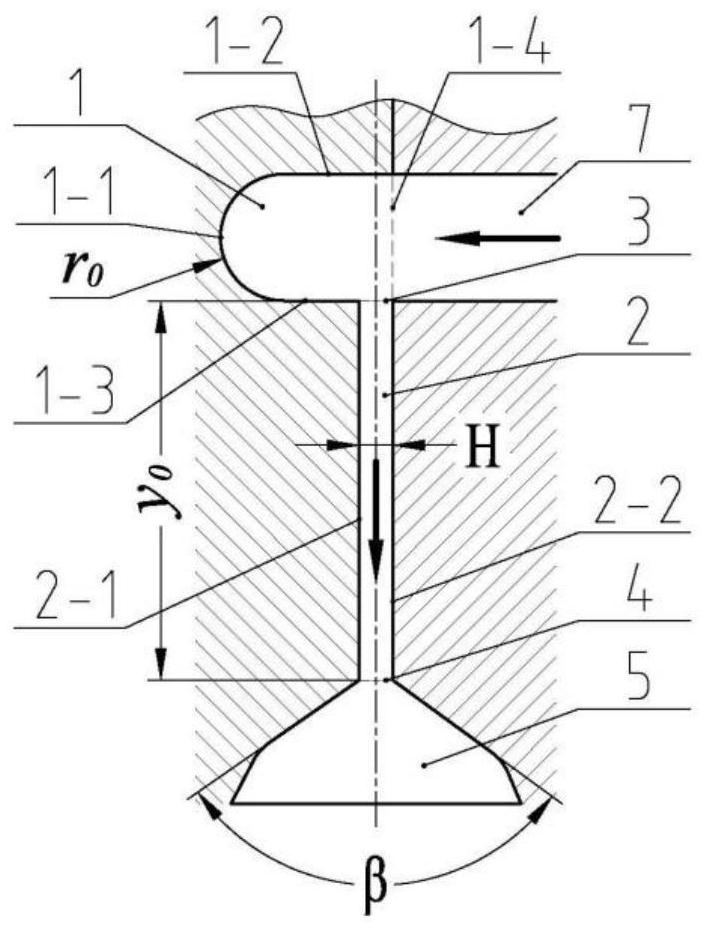

[0159] like figure 1 and 2 As shown, a clothes hanger-shaped spinning die flow channel structure for evenly distributing the melt, the die flow channel structure includes a manifold 1 and a slit flow channel 2; the manifold 1 is arranged in the slit flow the upper part of road 2;

[0160] Wherein, the manifold 1 is in the shape of a clothes hanger; the manifold 1 is a horizontal U-shaped structure, and the horizontal U-shaped structure includes a bottom end 1-1, a first side wall 1-2 of the manifold, a second manifold Two side walls 1-3 and the third side wall 1-4 of the manifold, the bottom end 1-1 of the horizontal U-shaped structure is a semicircular structure with a radius r, and the first side wall 1-2 of the manifold One end is connected tangentially to one side of the bottom end 1-1 of the horizontal U-shaped structure, and the other end of the first side wall 1-2 of the manifold is vertically connected to the third side wall 1-4 of the manifold , one end of the seco...

Embodiment 2

[0178] like figure 1 and figure 2 As shown, the present embodiment provides a clothes-hanger-shaped spinning die, which includes the runner structure of the clothes-hanger-shaped spinning die in Embodiment 1; the clothes-hanger-shaped spinning die also includes a feed pipe, and the feed The pipe communicates with the feed port on the third side wall 1-4 of the manifold of the horizontal U-shaped structure; the feed pipe is used to connect external equipment and transport the melt into the manifold 1; the hanger-shaped The spinning die head also includes a balance cavity 5 which communicates with the outlet 4 of the slit channel.

[0179] In a preferred embodiment of the present invention, the shape of the balance chamber 5 is not particularly limited, it can be a cavity with a specific volume, the upper end of the balance chamber communicates with the outlet of the slit flow channel, and the balance chamber The lower end can communicate with other spinning components; the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com