Low-phosphorus water retaining agent and application thereof

A water-retaining agent and phosphate technology, which is applied in the application, preservation of meat/fish with chemicals, and food ingredients as buffers, etc., can solve the problem of ineffectiveness, etc., and achieve the effect of improving the fiber structure and silkiness of chicken.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

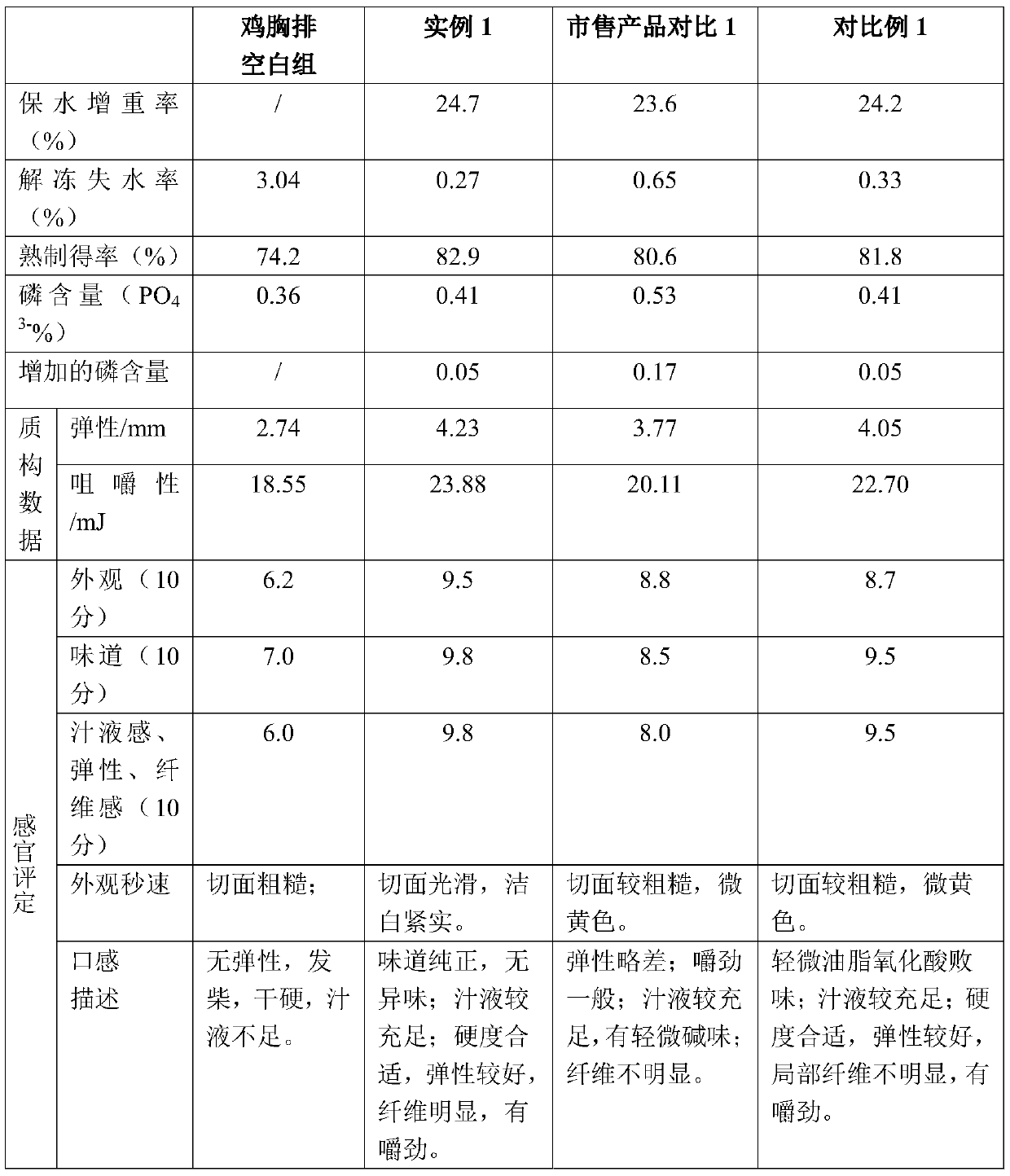

Embodiment 1

[0043] Example 1 - Chicken Breast Chops

[0044] a) Trim the chilled chicken breast, cut off the fat and superficial fascia;

[0045] b) Wash and drain the chicken breast meat obtained in step a, cut the chicken breast slices into a heart shape with a knife, and select a single weight of about 150 grams as raw meat;

[0046] c) Configure compound food additives:

[0047] 20 parts of high-focus complex sodium phosphate (apparent density 0.55-0.70g / cm 3, pH is 9.5 to 9.8, wherein the content of sodium pyrophosphate is 20-25%, the content of sodium tripolyphosphate is 75-80%), 3 parts of potassium dihydrogen phosphate, 7 parts of dipotassium hydrogen phosphate, 18 parts of potassium carbonate, 22 parts potassium bicarbonate; 5 parts anhydrous citric acid, 15 parts potassium citrate, 5 parts trehalose, 5 parts potassium chloride.

[0048] d) Add the compound food additive prepared in step c into purified water at 5°C and stir to dissolve, the amount of the compound food additiv...

Embodiment 2

[0065] Example 2 - Chicken Drumstick

[0066] a) Chilled boneless skin-on chicken upper leg meat (specification 70 / 80), trimmed to a length of 8 cm wide by 6 cm thick about 1 cm steak, washed and drained to obtain raw meat;

[0067] b) Configure compound food additives:

[0068] 20 parts of high-focus complex sodium phosphate (apparent density 0.55-0.70g / cm 3 , pH is 9.5 to 9.8, wherein the content of sodium pyrophosphate is 20-25%, the content of sodium tripolyphosphate is 75-80%), 3 parts of potassium dihydrogen phosphate, 7 parts of dipotassium hydrogen phosphate, 15 parts of potassium carbonate, 20 parts potassium bicarbonate; 7 parts anhydrous citric acid, 18 parts potassium citrate, 5 parts trehalose, 5 parts potassium chloride.

[0069] c) adding the compound food additive prepared in step b into purified water at 5° C., stirring and dissolving, the amount of the compound food additive is 0.4% of the weight of the meat, and the amount of water added is 20% of the weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com