A kind of high-hardness alloy processing equipment and its working method

A processing equipment, high hardness technology, applied in metal processing equipment, metal processing mechanical parts, measuring/indicating equipment and other directions, can solve the problem of inaccurate distance processing position, affecting the normal production of equipment, delaying the production cycle, etc., to improve product quality. The effect of quality, avoidance of clogging, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

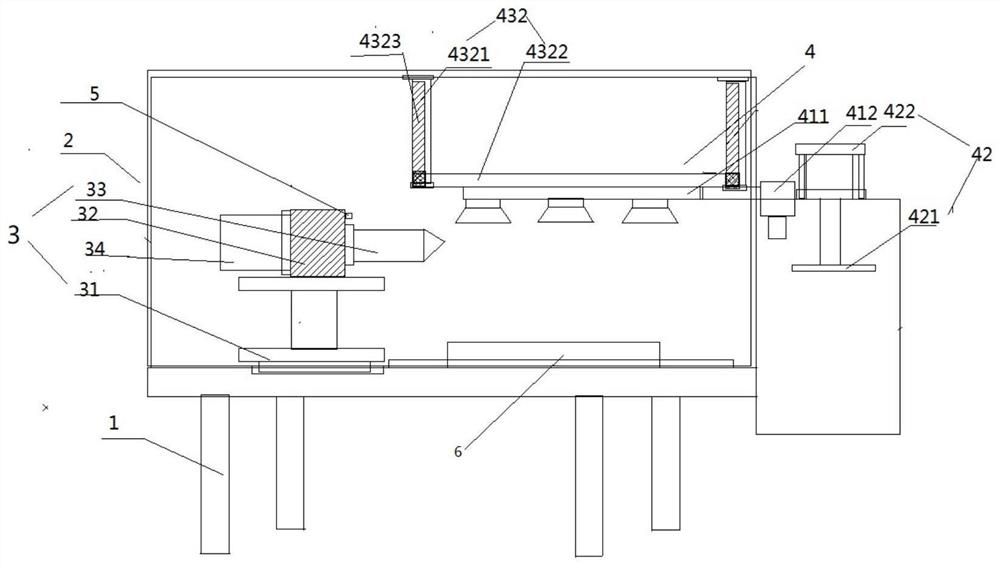

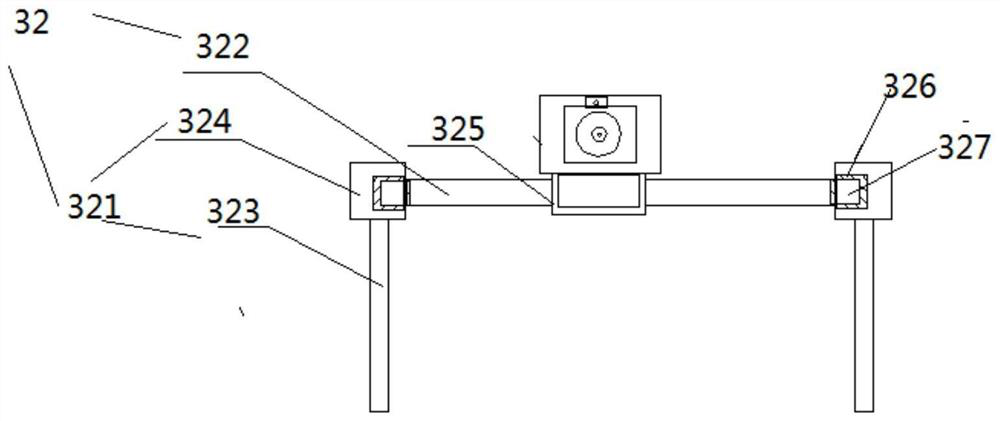

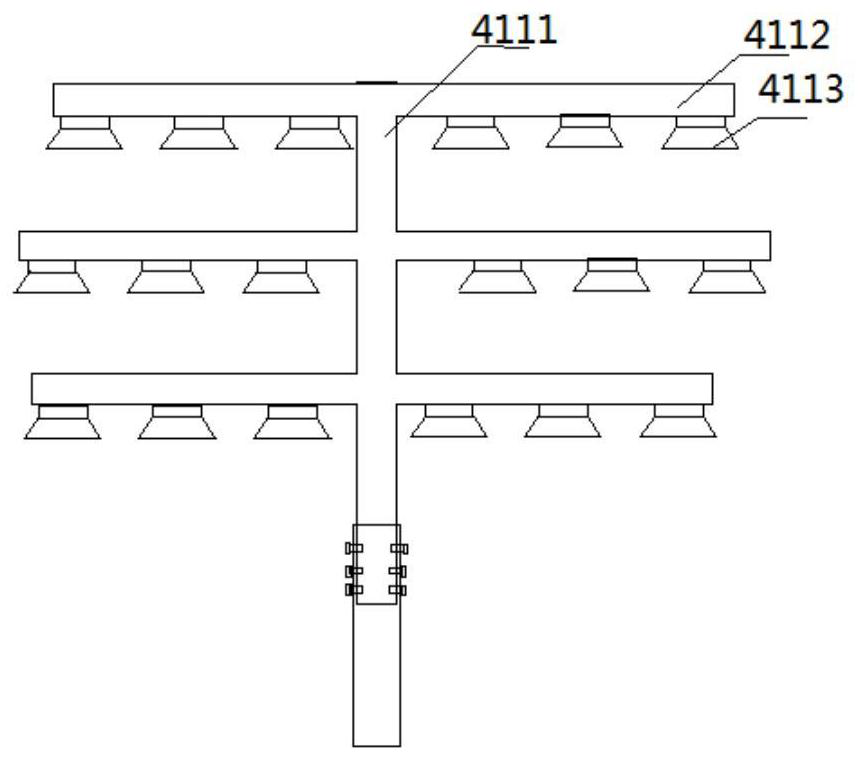

[0037] As shown in the figure, a high-hardness alloy processing equipment includes: a drilling machine, which is provided with a workbench 1, a casing 2, at least one position-adjustable machining center 3 and a waste recycling device 4, the casing 2 is set on the outside of the workbench 1, the workbench 1 is provided with a conveyor belt, the position-adjustable machining center 3 is installed on the workbench 1, and the position-adjustable machining center 3 is provided with a The detection mechanism 5 for detecting the processing position of the workpiece. The waste material recovery device 4 is provided with a waste material absorption mechanism and a waste material collection mechanism 42. The waste material absorption mechanism is connected with the casing 2 through a mounting bracket, and the waste material collection mechanism 42 is located on the drilling machine. One side, and connected with the waste absorbing mechanism, the position-adjustable machining center 3, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com