Technology and system for producing sintered magnesia from magnesium hydroxide

A technology of magnesium hydroxide and sintered magnesia, which is applied in the fields of magnesia, chemical industry, sustainable manufacturing/processing, etc., can solve the problems of ore quality decline, high production cost, and long process flow, and achieve low production cost and high production efficiency. The effect of low energy consumption and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

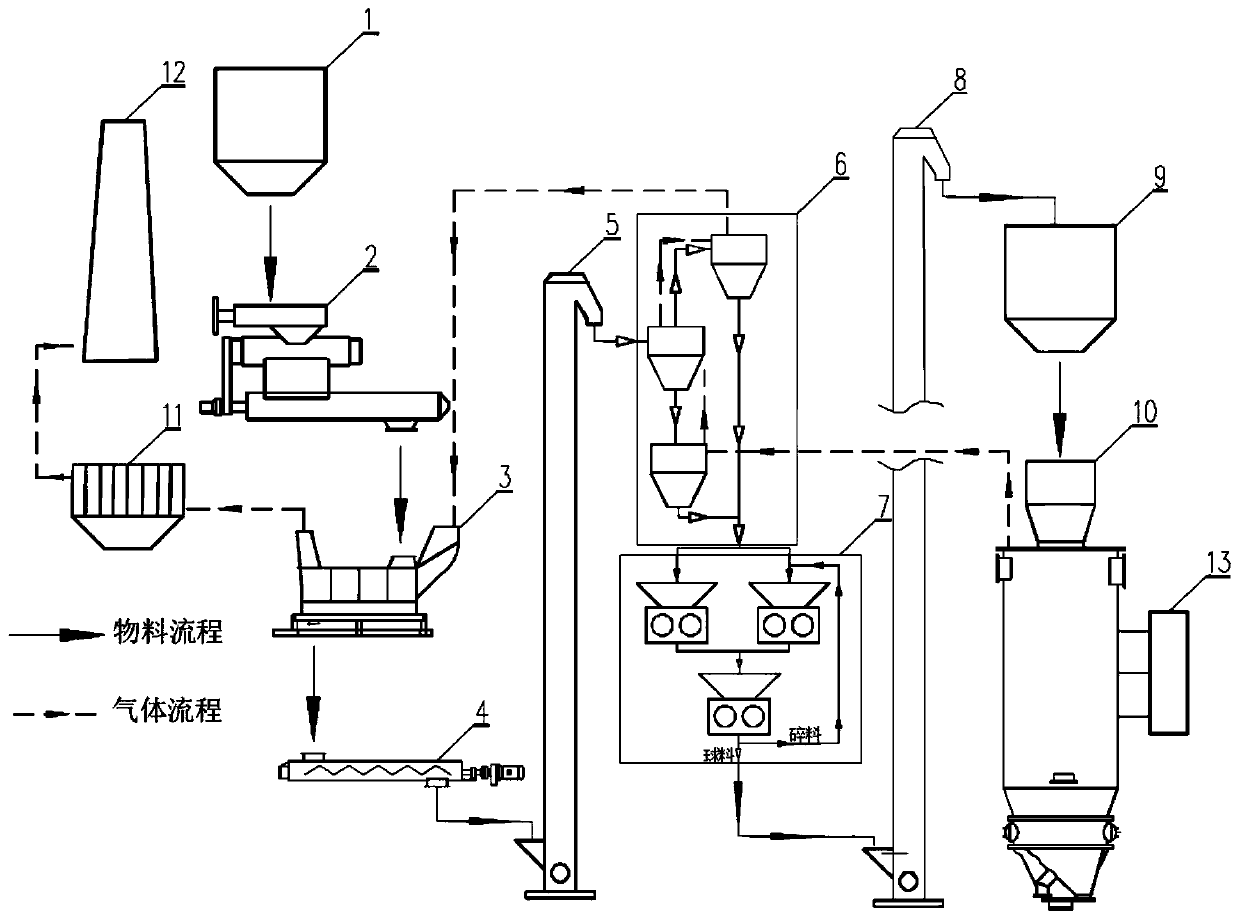

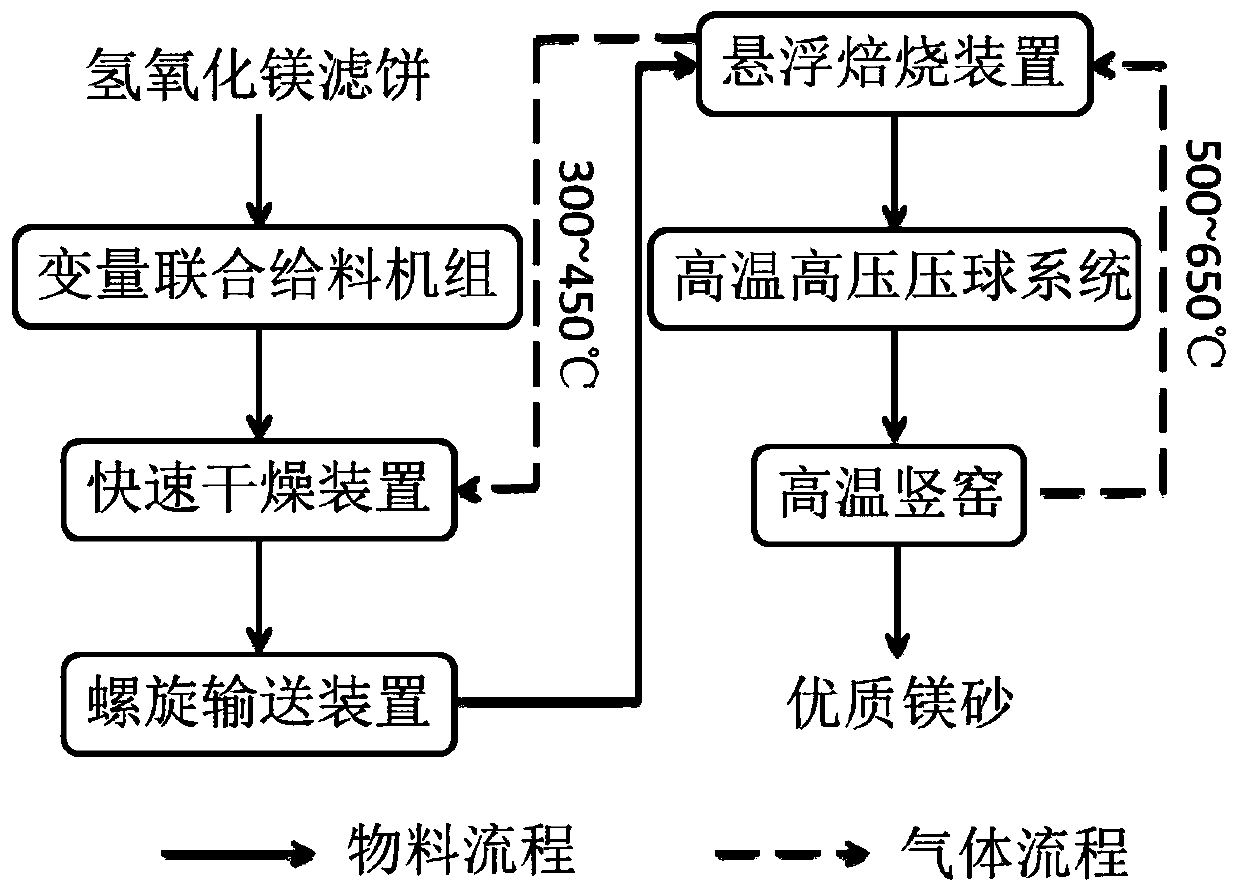

[0030] See figure 1 , figure 2 Shown, a kind of technology described in the present invention uses magnesium hydroxide as raw material to produce sintered magnesia, uses the magnesium hydroxide filter cake that seawater or brine makes as raw material, feeds through variable joint feeding unit 2, sends into fast Drying is carried out in the drying device 3, and the dried magnesium hydroxide powder is transported to the suspension roasting device 6 by a shaftless screw conveyor 4 for roasting to obtain high-activity magnesium oxide powder; The system 7 carries out circulating hot-pressed balls and sends them to the high-temperature shaft kiln 10 for calcination to obtain sintered magnesia products.

[0031] The variable variable combined feeding unit 2 is composed of a manual gate valve, a star feeder, a screw conveyor, a crushing machine and a f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com