Unpowered black water and gray water separation septic tank for rural areas

A septic tank and separation technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, anaerobic digestion treatment, etc., can solve the adverse effects of manure reuse on human health and inactivation of pathogenic microorganisms Thorough, incomplete fermentation of feces and other problems, to achieve the effect of eliminating cross-flow of sewage, improving safety and convenience, and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

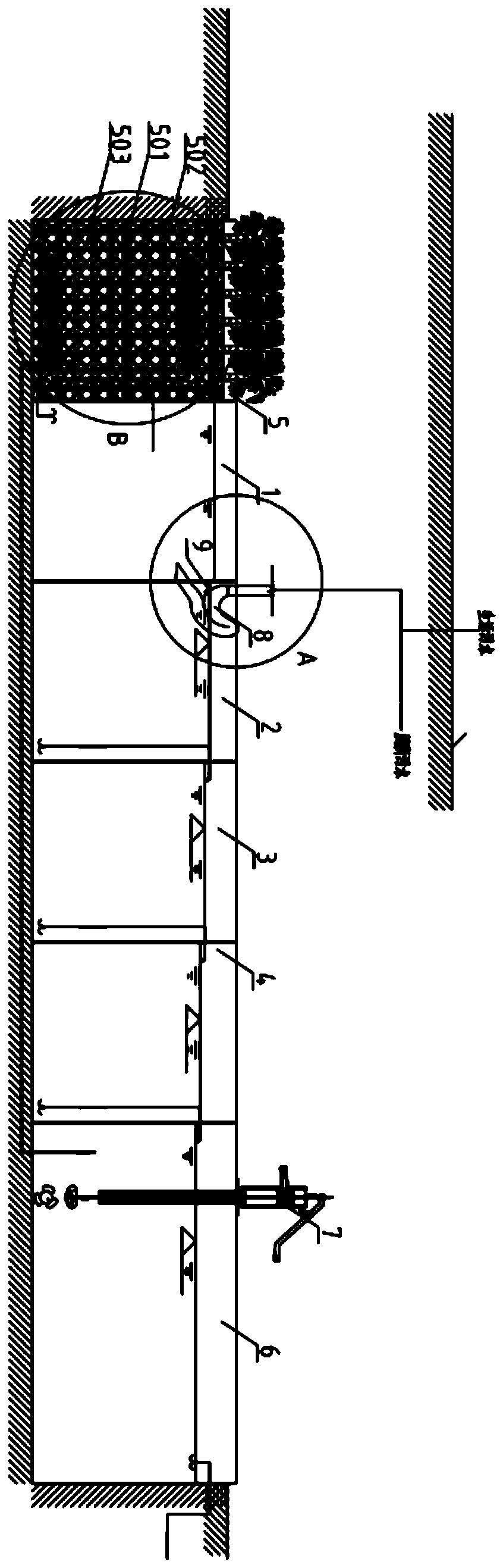

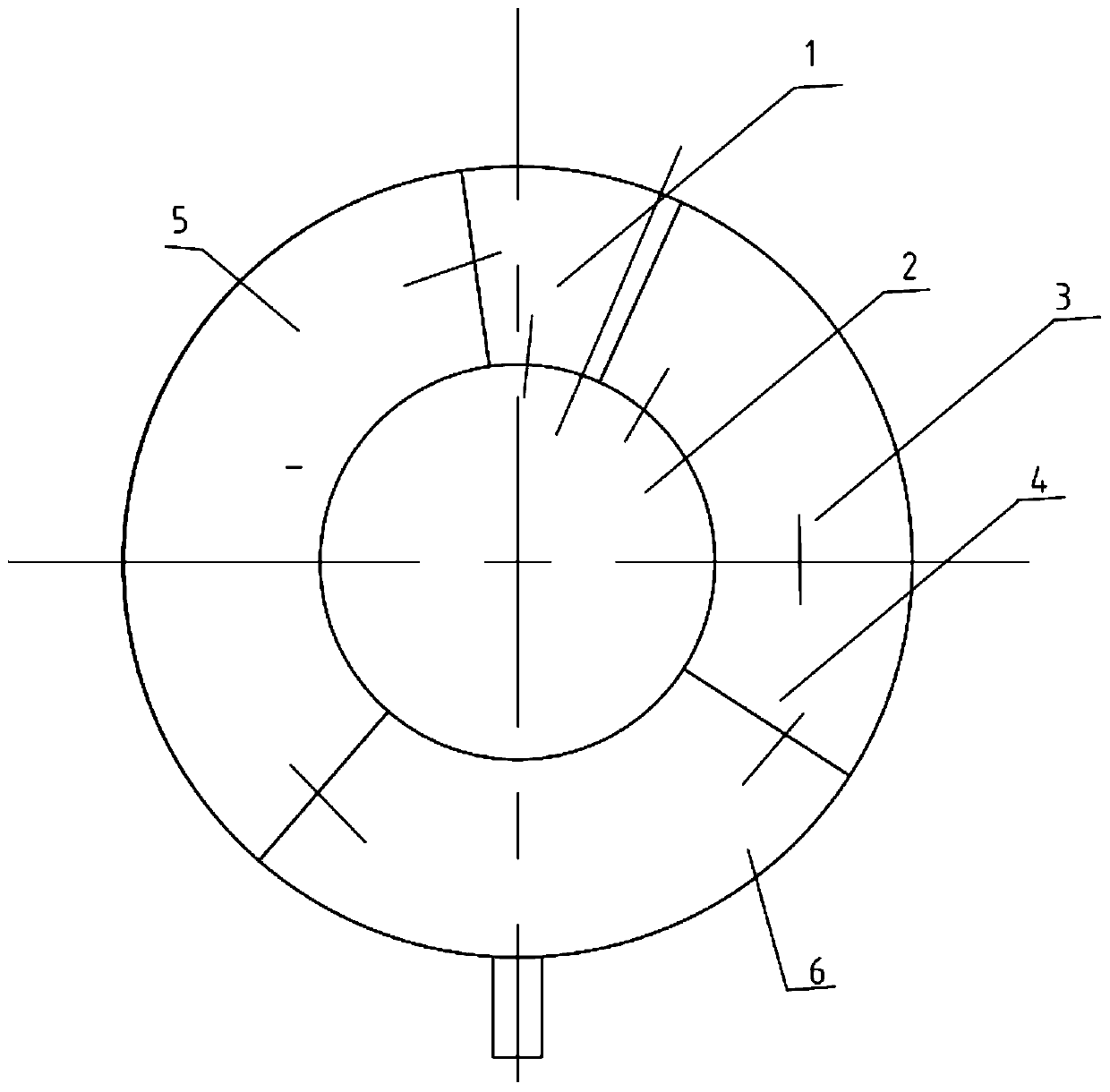

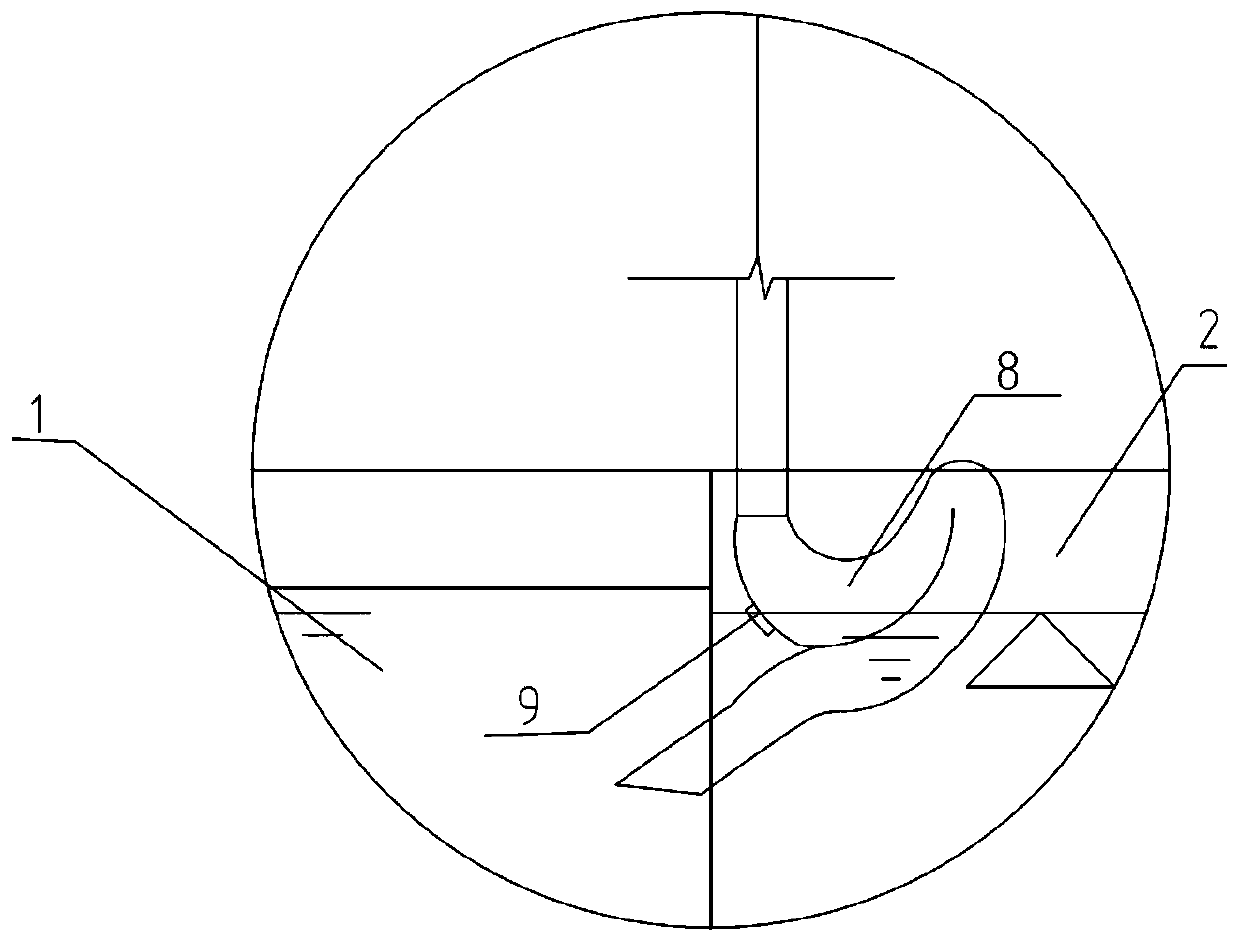

[0035] The rural black water and gray water separation septic tank includes a regulating tank 1, a clean water tank 6, a constructed wetland-fuel cell treatment system 5 and at least two levels of septic tanks connected in sequence, wherein the regulating tank 1 is connected to the first level of septic tanks. The pools are adjacent, and the black water and gray water enter the first-stage septic tank and regulating tank 1 respectively through the control of the black-ash water separator. The upper end of the first-stage septic tank is provided with an overflow port, and the first-stage septic tank The clear water in the pond overflows to the septic tank of the second level, and by analogy, the water of the septic tank of the last level overflows to the clear water pool 6.

[0036] Black water is mainly water from toilets and squatting pans, while gray water is water from washbasins and floor drains.

[0037] figure 1 Among them, the rural black water and gray water separatio...

Embodiment 2

[0047] Preparation of hydrothermal charcoal from bovine biogas residue: The raw material of biogas residue is taken from a dairy farm with a well-run biogas project in Banan District, Chongqing City, and coarse particles are removed. Take 15g of cow marsh residue and place it in a polytetrafluoroethylene-lined autoclave, add 80mL of deionized water, and stir for 30min to make it soak. Microwave heating under the conditions of 2.0Mpa, 2.5Mpa and 3.0Mpa respectively (the power is 400W, and the heating temperature is about 193°C). After carbonization for 2 hours, take it out and cool it to room temperature, separate the black precipitate, wash it with deionized water until it is neutral, and freeze it. Dry and grind for later use. The samples prepared at different temperatures were denoted as HTC1, HTC2 and HTC3, respectively.

[0048] Fe 3 o 4 Preparation of modified bovine biogas residue hydrothermal charcoal: The modified hydrothermal charcoal was prepared by a one-step met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com