Quantum dot film and preparation method thereof

A technology of thin film preparation and quantum dots, which is applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of restricted luminescence stability, limited application, and reduced quantum efficiency, and achieves good stability of quantum dots, narrow emission spectrum, and quantum high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

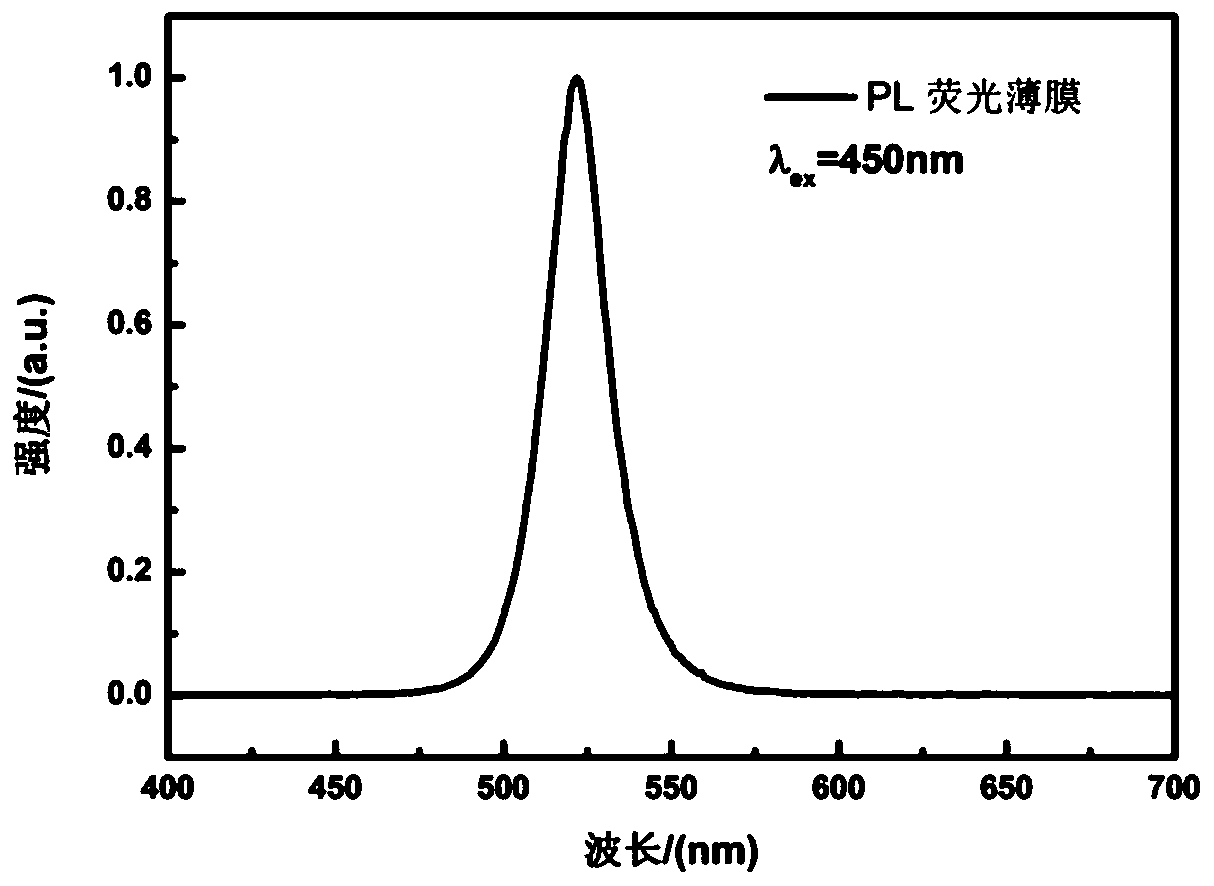

[0046] Embodiment 1: This embodiment provides a quantum dot film based on perovskite quantum dot glass

[0047] The quantum dots include a multi-layer fluorescent film, wherein each layer of fluorescent film contains a perovskite quantum dot glass powder component and a binder component; the mass ratio of the perovskite quantum dot glass powder to the binder is 0.1 to 0.5 :1. The perovskite quantum dot glass powder includes a glass matrix and a perovskite matrix, wherein the molar percentage of the perovskite matrix is 10% to 30% of the glass matrix; the glass matrix is Na 2 O, ZnO, B 2 o 3 , SiO 2 and BaO mixture; the perovskite matrix is Cs 2 CO 3 , PbX 2 and NaX mixture, or CsX and PbX 2 Mixture, wherein X is Cl, Br or I.

[0048] Compound Cs in perovskite matrix 2 CO 3 :PbX 2 : NaX molar ratio is 1:0.5~8:1 or CsX:PbX 2 1:0.5~4.

[0049] Na in glass powder 2 O: 10~20wt.%, ZnO: 10~20wt.%, B 2 o 3 :30~50wt.%, SiO 2 :20~30wt.%,BaO:5~15wt.%,Cs 2 CO 3 :1...

Embodiment 2

[0057] (1) Analytical pure Na 2 O, ZnO, B 2 o 3 , SiO 2 , BaO, Cs 2 CO 3 , PbBr, NaBr, according to: Na 2 O: 10wt.%, ZnO: 15wt.%, B 2 o 3 : 35wt.%, SiO 2 : 20wt.%, BaO: 5wt.%, Cs 2 CO 3 : 5%, PbBr 2 : 5wt.%, NaBr: 5wt.% mole fraction ratio is accurately weighed and placed in an agate mortar, ground evenly in the agate mortar, placed in a corundum crucible, and placed in a muffle furnace at 1150°C Insulate for 10 minutes, then take out the glass melt and quickly cast it in an iron plate mold with a preheating temperature of 250°C to form a transparent glass, heat for 2 hours to eliminate internal stress; then transfer it to a muffle furnace for annealing at 430°C for 5 hours, After natural cooling, the perovskite quantum dot glass can be obtained, and then the cooled perovskite quantum dot glass is ground and passed through a 200-mesh sieve to obtain perovskite quantum dot glass powder;

[0058] (2) Weigh A silica gel, B silica gel, and 5g, 10g, and 3g of the above-...

Embodiment 3

[0062] (1) Analytical pure Na 2 O, ZnO, B 2 o 3 , SiO 2 , BaO, Cs 2 CO 3 , PbI, NaI, according to: Na 2 O: 10wt.%, ZnO: 10wt.%, B 2 o 3 : 30wt.%, SiO 2 : 20wt.%, BaO: 9wt.%, Cs 2 CO 3 : 5wt.%, PbI 2 : 12wt.%, NaI: 6wt.% mole fraction ratio is accurately weighed and placed in an agate mortar, ground evenly in the agate mortar, placed in a corundum crucible, and placed in a muffle furnace at 1150°C Insulated for 10 minutes, and then, the glass melt was taken out and quickly cast in a steel mold with a preheating temperature of 250°C to obtain a transparent glass, and held for 2 hours to eliminate internal stress; then transferred to a muffle furnace for annealing at 480°C for 10 hours, and naturally After cooling, the perovskite quantum dot glass can be obtained, and then the cooled perovskite quantum dot glass is ground and passed through a 200-mesh sieve to obtain perovskite quantum dot glass powder;

[0063] (2) Weigh 10g, 10g, and 3g of A silica gel, B silica gel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com