Microbial cellulose membrane/nanometer noble metal composite material, preparation method and applications thereof

A microbial cellulose and composite material technology is applied in the field of microbial cellulose film/nano precious metal composite material and its preparation, and achieves the effects of safe preparation process, cheap raw materials, and good surface-enhanced Raman scattering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

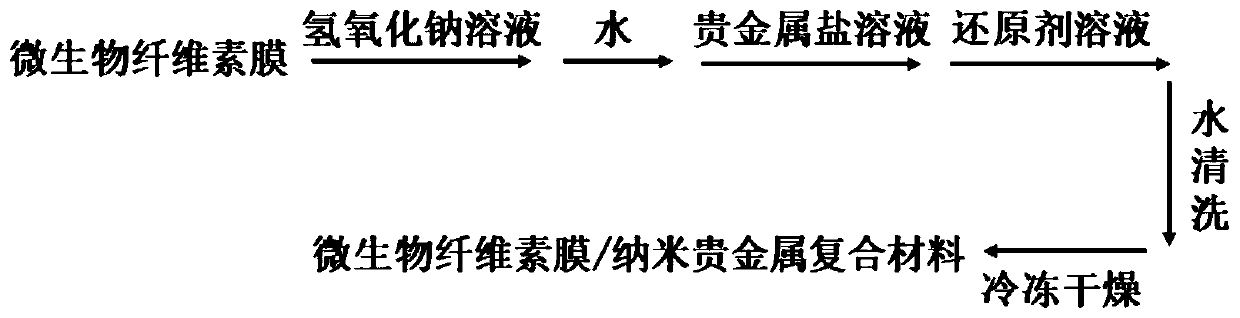

Method used

Image

Examples

Embodiment 1

[0037] S1. Soak the microbial cellulose membrane with a thickness of 1mm, which is synthesized by Acetobacter fermentation, in 0.5% sodium hydroxide solution, treat it at 100°C for 2h, and then soak it in deionized water at 100°C for 2h, this step Repeat once to remove impurities in the microbial cellulose membrane. Then use deionized water to shake repeatedly until the cleaning solution is neutral;

[0038] S2. Soak the S1 purified microbial cellulose membrane in a 0.01mol / L silver nitrate solution, and soak for 12 hours at 30°C in the dark;

[0039] S3. Separate the microbial cellulose membrane soaked in S2, rinse the surface 5 times with deionized water to remove the unbound silver ions, and then soak the microbial cellulose membrane in a 0.05mol / L glucose solution. Soak in dark at 30℃ for 48h;

[0040] S4. Separate the microbial cellulose membrane soaked in S3, and wash with deionized water until the cleaning solution does not contain silver ions;

[0041] S5. The S4 treated mic...

Embodiment 2

[0047] S1. Soak the microbial cellulose membrane with a thickness of 1mm, which is synthesized by Acetobacter fermentation, in 0.5% sodium hydroxide solution, treat it at 100°C for 2h, and then soak it in deionized water at 100°C for 2h, this step Repeat once to remove impurities in the microbial cellulose membrane. Then use deionized water to shake repeatedly until the cleaning solution is neutral;

[0048] S2. Soak the S1 purified microbial cellulose membrane in a 0.1mol / L silver nitrate solution, and soak it in the dark at 40℃ for 6h;

[0049] S3. Separate the microbial cellulose membrane soaked in S2, wash the surface with deionized water 5 times to remove the unbound silver ions, and then soak the microbial cellulose membrane in 0.2mol / L glucose solution. Soak in dark at 60℃ for 24h;

[0050] S4. Separate the microbial cellulose membrane soaked in S3, and wash with deionized water until the cleaning solution does not contain silver ions;

[0051] S5. The S4 treated microbial ce...

Embodiment 3

[0053] S1. Soak the microbial cellulose membrane with a thickness of 1mm, which is synthesized by Acetobacter fermentation, in 0.5% sodium hydroxide solution, treat it at 100°C for 2h, and then soak it in deionized water at 100°C for 2h, this step Repeat once to remove impurities in the microbial cellulose membrane. Then use deionized water to shake repeatedly until the cleaning solution is neutral;

[0054] S2. Soak the S1 purified microbial cellulose membrane in a 0.05mol / L silver nitrate solution, and soak for 12 hours at 50°C in the dark;

[0055] S3. Separate the microbial cellulose membrane soaked in S2, rinse the surface with deionized water 5 times to remove the unbound silver ions, and then soak the microbial cellulose membrane in 0.1 mol / L glucose solution. Soak in dark at 40℃ for 36h;

[0056] S4. Separate the microbial cellulose membrane soaked in S3, and wash with deionized water until the cleaning solution does not contain silver ions;

[0057] S5. The S4 treated micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com