A kind of multifunctional thermal insulation, sound insulation and waterproof interior and exterior wall putty and its manufacturing method

A manufacturing method and multi-functional technology, applied in the direction of filling slurry, etc., can solve the problems of different shrinkage values, loss, shedding, etc., and achieve the effects of excellent waterproofness and elongation, good beautification and protection, and excellent resilience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

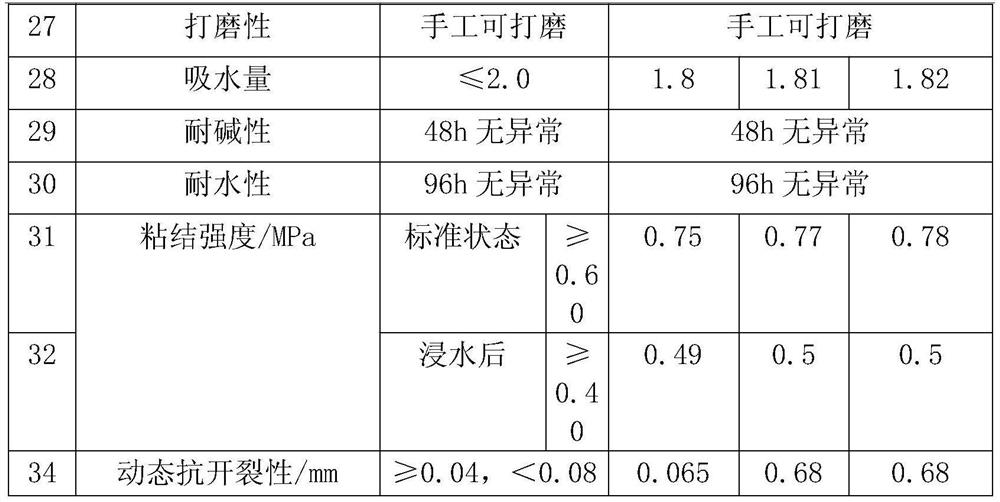

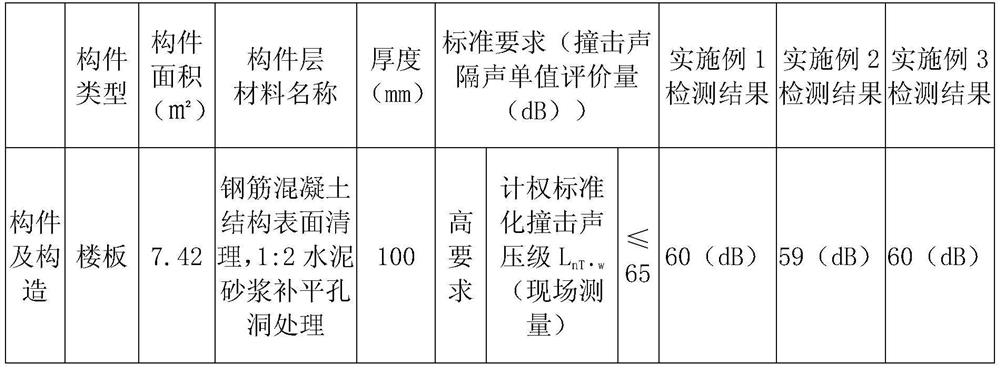

Embodiment 1

[0031] A multifunctional thermal insulation, sound insulation and waterproof putty for interior and exterior walls, which comprises the following components: 50 parts of multifunctional emulsion, 15 parts of aluminum silicate ceramic fiber, 25 parts of zirconia hollow microspheres, 1 part of titanium dioxide, 2 parts of dispersant, 0.5 part of defoamer, 1 part of suspending agent.

[0032] The multifunctional emulsion includes 25 parts of deionized water, 40 parts of VAE emulsion, 25 parts of silicone zirconium, 1 part of defoamer, 5 parts of bactericide, 3.5 parts of leveling agent, and 2 parts of thickener.

[0033] A method for manufacturing multifunctional thermal insulation, sound insulation and waterproof interior and exterior wall putty, characterized in that it comprises the following steps:

[0034] (1) Prepare a high-speed disperser, adjust the speed to 200 rpm, first add deionized water, VAE emulsion, and silicone zirconium emulsion and stir for 15 minutes to obtain...

Embodiment 2

[0040] A multifunctional thermal insulation, sound insulation and waterproof putty for interior and exterior walls, which includes the following components: 52 parts of multifunctional emulsion, 18 parts of aluminum silicate ceramic fiber, 28 parts of zirconia hollow microspheres, 1 part of titanium dioxide, 3 parts of dispersant, 0.7 parts of defoamer, 1.5 parts of suspending agent.

[0041] The multifunctional emulsion includes 30 parts of deionized water, 43 parts of VAE emulsion, 260 parts of silicone zirconium, 2 parts of defoamer, 6 parts of bactericide, 4 parts of leveling agent, and 3 parts of thickener.

[0042]A method for manufacturing multifunctional thermal insulation, sound insulation and waterproof interior and exterior wall putty, characterized in that it comprises the following steps:

[0043] (1) Prepare a high-speed disperser, adjust the speed to 300 rpm, first add deionized water, VAE emulsion, and silicone zirconium emulsion and stir for 20 minutes to obta...

Embodiment 3

[0049] A multifunctional thermal insulation sound insulation waterproof interior and exterior wall putty, which includes the following components: 55 parts of multifunctional emulsion, 20 parts of aluminum silicate ceramic fiber, 30 parts of zirconia hollow microspheres, 2 parts of titanium dioxide, 5 parts of dispersant, 1 part of defoamer, 2 parts of suspending agent.

[0050] The multifunctional emulsion includes 35 parts of deionized water, 45 parts of VAE emulsion, 30 parts of silicone zirconium, 2 parts of defoamer, 8 parts of bactericide, 5 parts of leveling agent, and 5 parts of thickener.

[0051] A method for manufacturing multifunctional thermal insulation, sound insulation and waterproof interior and exterior wall putty, characterized in that it comprises the following steps:

[0052] (1) Prepare a high-speed disperser, adjust the speed to 400 rpm, first add deionized water, VAE emulsion, and silicone zirconium emulsion and stir for 25 minutes to obtain a mixed emu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com