A kind of high-performance composite additive for natural ester insulating oil and preparation method thereof

A compound additive and high-performance technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of not effectively improving the performance of natural ester insulating oil, achieve good oxidation resistance, simple preparation process, and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

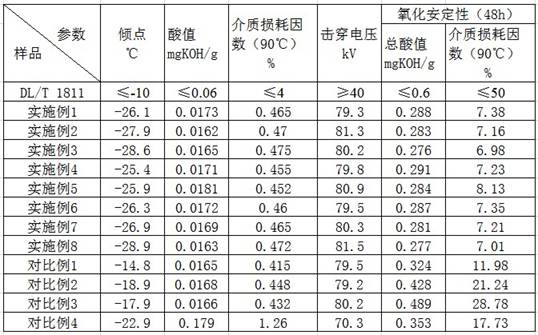

Examples

Embodiment 1

[0030] A high-performance composite additive for natural ester insulating oil, which is composed of naphthenic transformer oil, antioxidant, pour point depressant and metal passivator, wherein the antioxidant tert-butyl hydroquinone accounts for 10% of the weight of the additive, and the anti-oxidant Oxidant 4,4 methylene (2.6-di-tert-butylphenol) accounts for 8% of the additive weight, pour point depressant hexylnaphthalene accounts for 8% of the additive weight, pour point depressant polymethacrylate accounts for 5% of the additive weight, The metal deactivator benzotriazole derivatives accounted for 8% by weight of the additive.

[0031] The preparation method is as follows:

[0032] 1) Under the vacuum conditions of 100r / min and -0.096Mpa, the naphthenic transformer oil was heated to 75℃, and after stirring for 30min, the antioxidant of the above proportion was slowly added. Ultrasonic dispersion treatment, ultrasonic power 100W, ultrasonic frequency 30kHz, ultrasonic tre...

Embodiment 2

[0037] A high-performance composite additive for natural ester insulating oil, which is composed of naphthenic transformer oil, antioxidant, pour point depressant and metal passivator, wherein the antioxidant tert-butyl hydroquinone accounts for 11% of the weight of the additive, and the anti-oxidant The oxidant tetrakis[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol accounts for 8% of the additive weight, the pour point depressant octylnaphthalene accounts for 9% of the additive weight, the pour point depressant polymer Acrylic acid higher alcohol ester accounts for 5% by weight of the additive, and the metal deactivator benzotriazole derivative accounts for 8% by weight of the additive.

[0038] The preparation method is as follows:

[0039] 1) Under the vacuum conditions of 80r / min and -0.1Mpa, heat naphthenic transformer oil to 72℃, and after stirring for 35min, slowly add the antioxidant in the above proportion, and at the same time adopt the cycle...

Embodiment 3

[0044] A high-performance composite additive for natural ester insulating oil, which is composed of polyalphaolefin synthetic oil, antioxidant, pour point depressant and metal passivator, wherein antioxidant tetrakis[beta-(3,5-di-tert-butyl-4 -Hydroxyphenyl) propionic acid] pentaerythritol ester accounts for 10% by weight of additives, antioxidant 4,4 methylene (2.6-di-tert-butylphenol) accounts for 10% by weight of additives, pour point depressant octyl naphthalene accounts for 10% by weight of additives 15% of the metal passivator methyl benzotriazole derivative accounts for 8.5% of the additive weight;

[0045] The preparation method is as follows:

[0046] 1) Heat the polyalphaolefin synthetic oil to 72°C under vacuum conditions of 100r / min and -0.1Mpa, stir for 30min and slowly add the antioxidants in the above proportions. Ultrasonic dispersion treatment, ultrasonic power 160W, ultrasonic frequency 36kHz, ultrasonic treatment time 15min, continuous stirring for 40min; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com