Genetically engineered bacterium for synthesizing D-limonene, and construction method and application of genetically engineered bacterium

A technology of genetically engineered bacteria and limonene, which is applied in the field of genetic engineering and fermentation engineering, can solve the problems of low D-limonene biosynthesis level and restrictions on the industrial production of D-limonene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

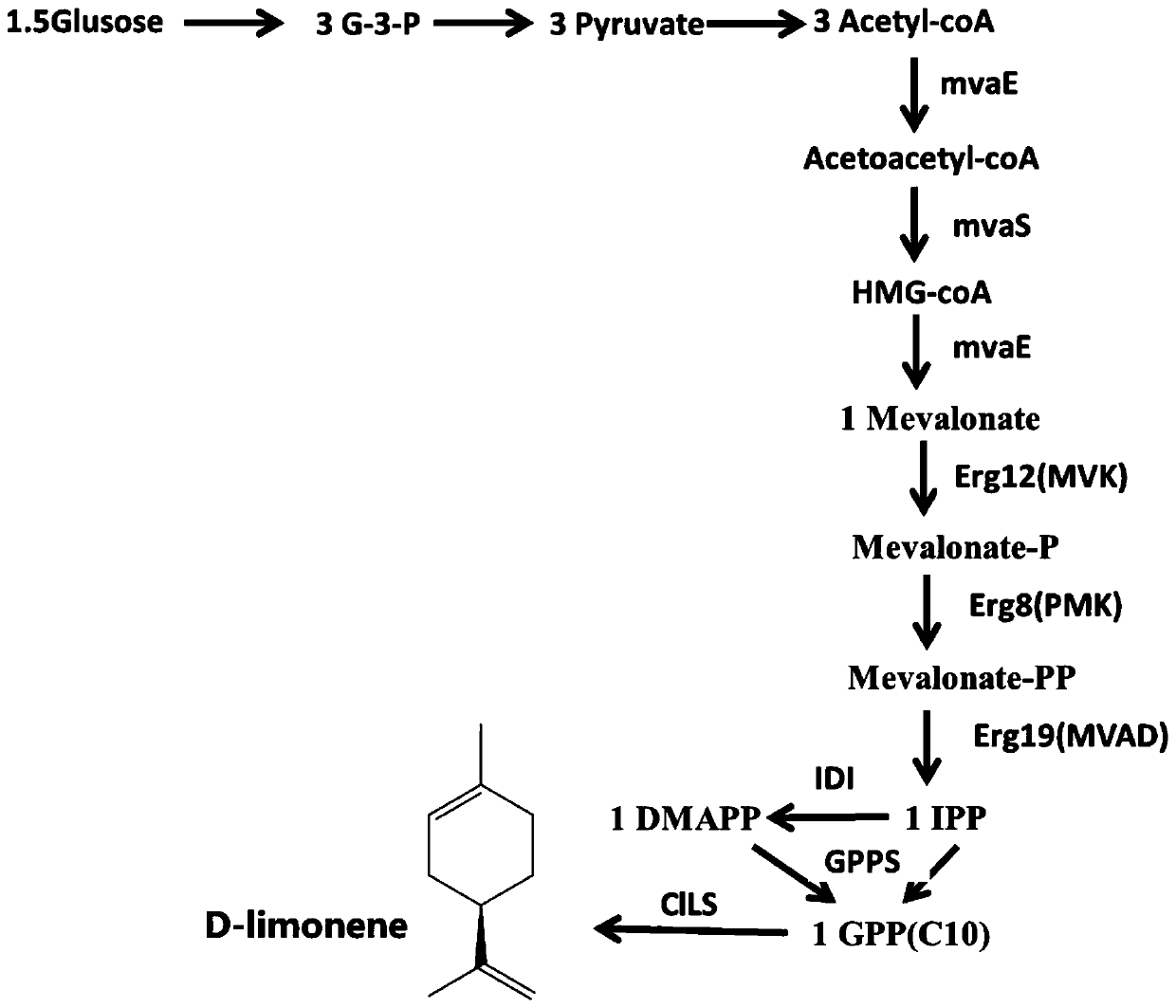

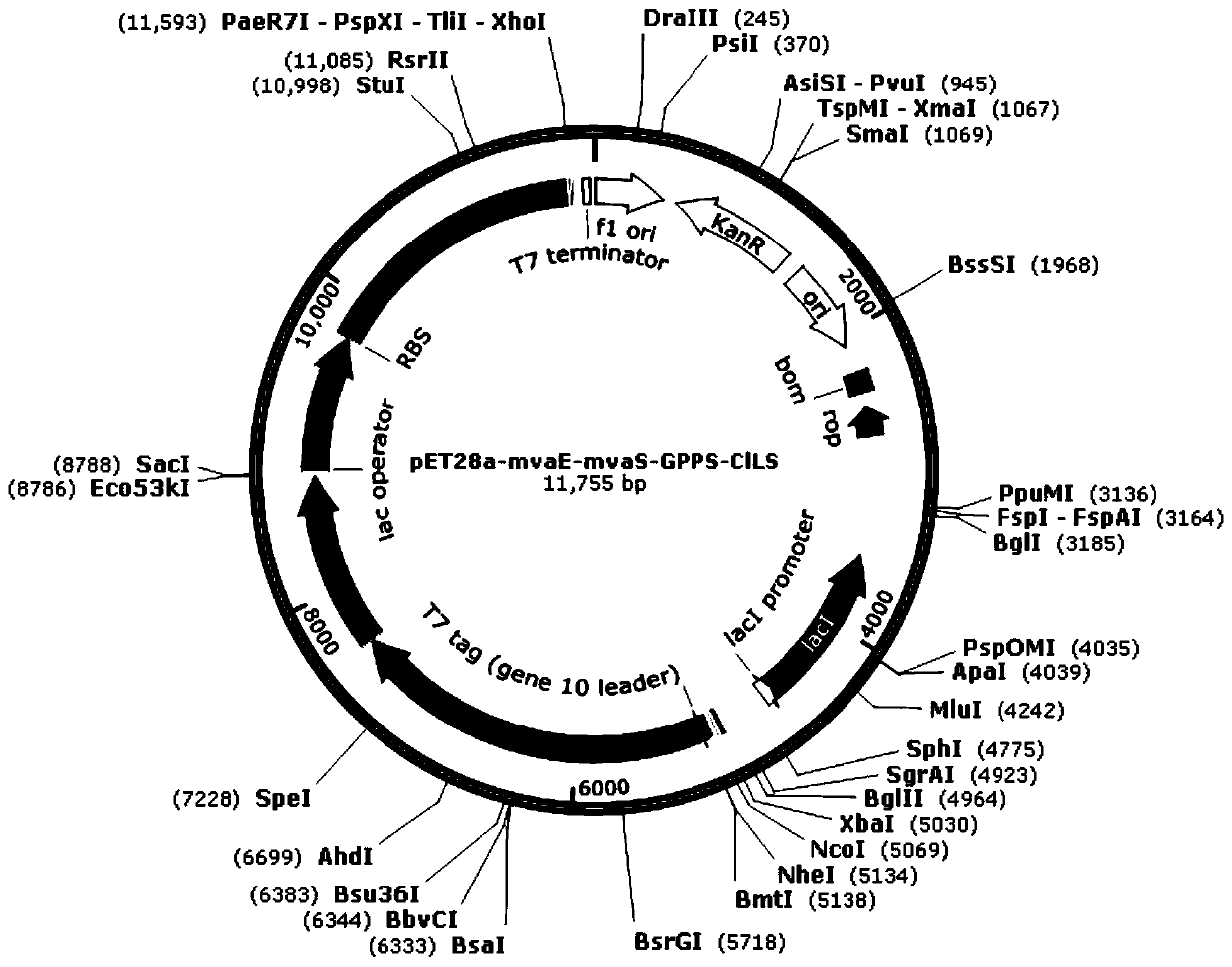

[0042] Embodiment 1. The construction of the genetically engineered bacteria that synthesizes D-limonene.

[0043] The genetically engineered bacteria for synthesizing D-limonene described in this example express HMG-CoA synthetase gene mvaS, acetyl CoA acetyltransferase mvaE, geranyl pyrophosphate synthase GPPS gene, D-limonene synthase gene ClLS, MVA kinase ERG12 gene, MVAP kinase ERG8 gene, mevalonate decarboxylase ERG19 gene, isopentyl pyrophosphate isomerase IDI gene, and the host bacteria is Escherichia coli. The HMG-CoA synthase gene mvaS, GeneBank ID is AAG02439, derived from E. Phosphate synthase GPPS gene, Genbank No. AF5131121, from Abies grandis; D-limonene synthase ClLS gene, Genbank No.AF514287.1, from Citruslimon; MVA kinase ERG12 gene, GeneBank ID: 855248, from Saccharomyces cerevisiae; MVAP kinase ERG8 gene, GeneBank ID: 855260, source Saccharomyces cerevisiae, mevalonate decarboxylase ERG19 gene, GeneBank ID: 855779, source Saccharomyces cerevisiae, isopenty...

Embodiment 2

[0057] Example 2. Fermentative production of D-limonene by genetically engineered strains.

[0058] Shake flask fermentation experiment:

[0059] 1) Cultivation of the primary seed liquid: Inoculate the Example 1 on the solid LB plate in the LB seed liquid medium to obtain a single colony of the recombinant strain, and add a final concentration of 50 μg / mL kanamycin and 100 μg / ml ampicillin , grow at 37°C for 12h, and obtain the primary seed solution.

[0060] 2) Transfer the primary seed solution obtained in step 1) to a 250mL saline bottle with 2% (wt) inoculation amount, containing 50mL fermentation medium, and add 200g / L of MgSO when transferring the seed solution 4 ·7H 2 O 100μL, 500g / L glucose 2.4mL, 1000×trace elements 50μL ((NH 4 ) 6 MoO 24 4H 2 O 0.37g; ZnSO 4 ·7H 2 O 0.29g; H 3 BO 4 2.47g; CuSO 4 ·5H 2 O 0.25g; MuCl 2 4H 2O 1.58g; distilled water to 100mL), final concentration of 50μg / mL kanamycin and 100μg / ml ampicillin, culture at 37°C and 180rpm.

...

Embodiment 3

[0074] Example 3. Fermentative production of D-limonene by genetically engineered strains.

[0075] Shake flask fermentation experiment:

[0076] 1) Cultivation of the primary seed liquid: Inoculate the Example 3 on the solid LB plate in the LB seed liquid medium to obtain a single colony of the recombinant strain, and add a final concentration of 50 μg / mL kanamycin and 100 μg / ml ampicillin , grow at 37°C for 12h, and obtain the primary seed solution.

[0077] 2) Transfer the primary seed solution obtained in step 1) to a 250mL saline bottle with 2% (wt) inoculation amount, containing 50mL fermentation medium, and add 200g / L of MgSO when transferring the seed solution 4 ·7H 2 O 100μL, 500g / L glucose 2.4mL, 1000×trace elements 50μL ((NH 4 ) 6 MoO 24 4H 2 O 0.37g; ZnSO 4 ·7H 2 O 0.29g; H 3 BO 4 2.47g; CuSO 4 ·5H 2 O 0.25g; MuCl 2 4H 2 O 1.58g; distilled water to 100mL), final concentration of 50μg / mL kanamycin and 100μg / ml ampicillin, culture at 37°C and 180rpm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com