A self-generating flexible electromagnetic fiber and its preparation method and application

A technology of self-generation and fiber, which is applied in the direction of spinning solution preparation, fiber chemical characteristics, material analysis through electromagnetic means, etc. It can solve the problems of heavy weight and difficulty in making fibers or fabrics, and achieve low cost, The equipment is simple and easy to operate, and the performance and thickness can be adjusted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

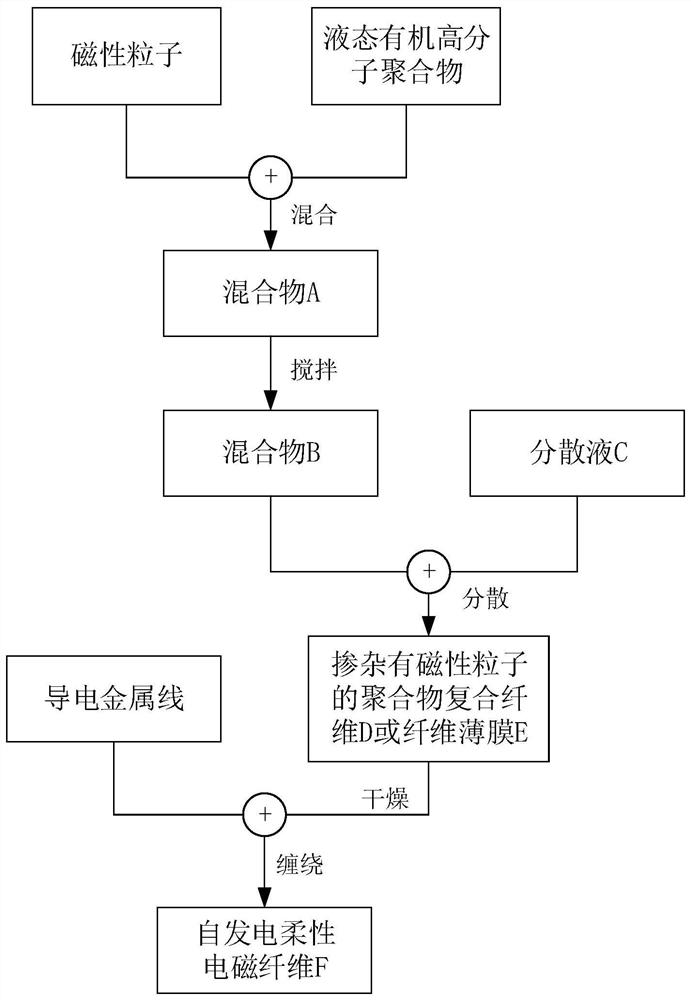

[0029] Specifically, a method for preparing self-generating flexible electromagnetic fibers of the present invention comprises the following steps:

[0030] (1) Adding magnetic particles with electromagnetic induction effect into the liquid organic polymer to form a mixture A;

[0031] (2) Fully stir the mixture A obtained in step (1) to form a uniform mixed solution B; wherein, the mass percent concentration of the liquid organic polymer in the mixed solution B is 30% to 90%, and the mass percent concentration of the magnetic particles 10% to 70%;

[0032] (3) Add absolute ethanol to the petri dish as dispersion liquid C;

[0033] (4) adding the mixed liquid B obtained in step (2) to the dispersion liquid C for dispersion to obtain a polymer composite fiber D or a fiber film E doped with magnetic particles;

[0034] (5) Dry the polymer composite fiber D or fiber film E obtained in step (4) to remove the solvent, and then wind and weave the conductive metal wire to form a fa...

Embodiment 1

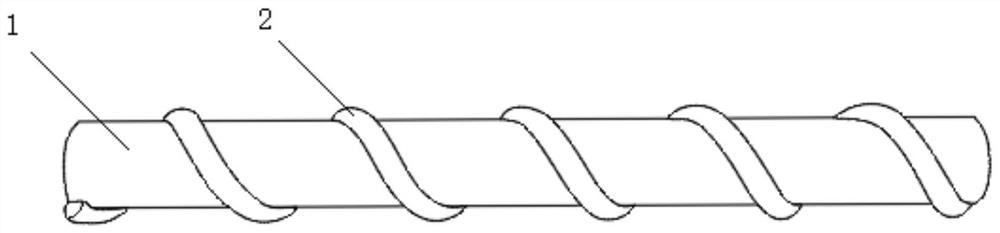

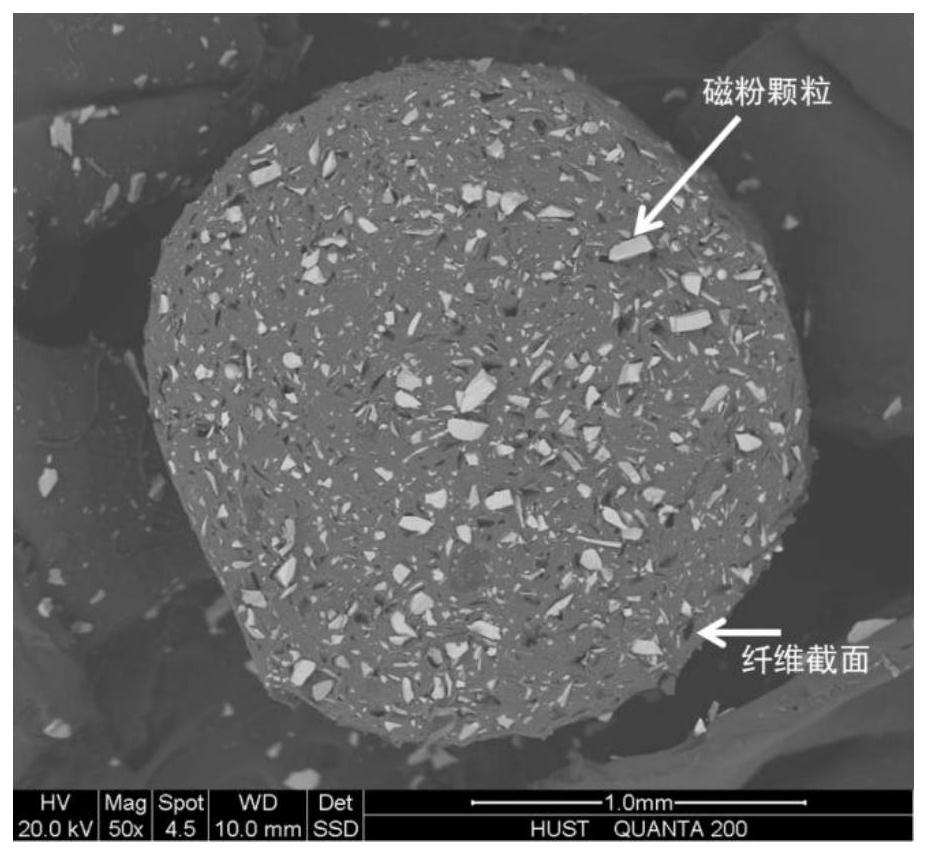

[0042]Add 10 grams of PBAT to the beaker to form a uniform liquid polymer; add 10 grams of NdFeB magnetic powder to the liquid polymer, and stir magnetically at 50 ° C for 1 hour to obtain a uniform mixed solution; add absolute ethanol to the culture and make the added absolute ethanol just cover the whole Petri dish to form a dispersion; add the uniform mixed solution into the injection needle and slowly extrude into the dispersion to obtain a fibrous polymer; Put the material into an oven, dry at 60°C for 12 hours, and volatilize the absolute ethanol to obtain the polymer composite fiber material 1 containing NdFeB magnetic powder; the polymer composite fiber material 1 containing NdFeB magnetic powder Cut off 5 cm, twist and weave with conductive gold wire 2 to form an electromagnetic fiber material capable of self-generating function, such as figure 2 and image 3 shown. The fiber material is put into a tensile tester, and stretched at a rate of 30mm / s to 50% deformatio...

Embodiment 2

[0044] Add 10 grams of PBAT to the beaker to form a uniform liquid polymer; add 15 grams of NdFeB magnetic powder to the liquid polymer, and stir magnetically at 50°C for 1 hour to obtain a uniform mixed solution; add absolute ethanol to the culture and make the added absolute ethanol just cover the whole Petri dish to form a dispersion; add the uniform mixed solution into the injection needle and slowly extrude into the dispersion to obtain a fibrous polymer; The material is put into an oven, dried at 60°C for 12 hours, and the absolute ethanol is volatilized to obtain a polymer composite fiber material containing NdFeB magnetic powder. The polymer composite fiber material containing NdFeB magnetic powder is cut into 5 cm, and it is wound and woven with conductive gold wire to form an electromagnetic fiber material that can generate electricity by itself. The fiber material is put into a tensile tester and stretched at a rate of 40mm / s to 50% deformation, and an induced elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com