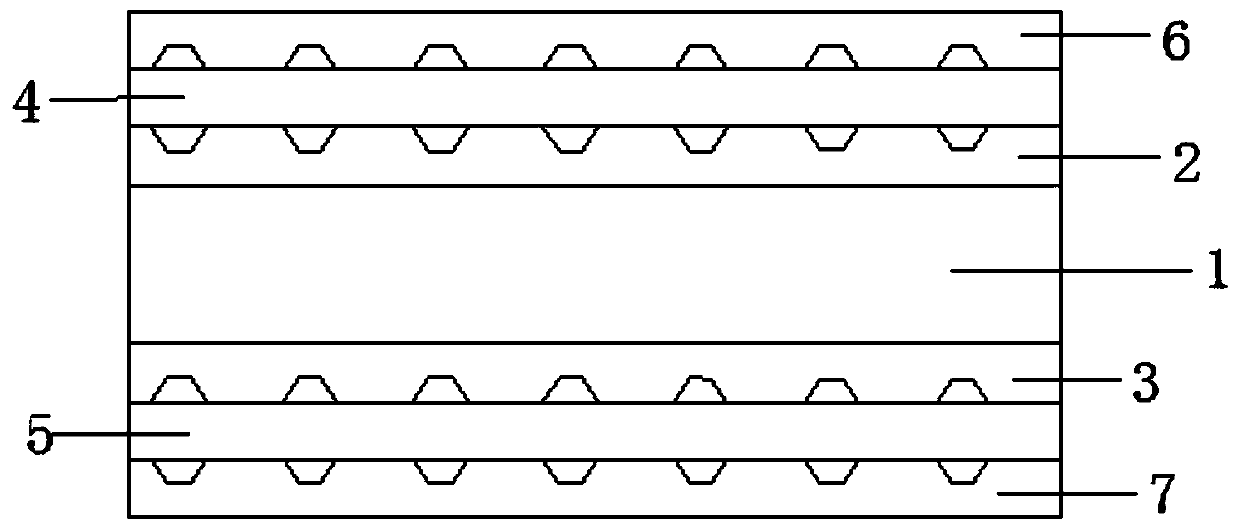

Outer wall heat insulation cement decorative board

A cement board and decorative board technology, applied in construction, building structure, covering/lining, etc., can solve problems such as durability defects, and achieve the effect of reducing noise transmission, improving thermal insulation and sound insulation, and improving overall strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, the mass parts of the upper fiber-reinforced cement slab 2 and the lower fiber-reinforced cement slab 3 are composed as follows: 100 parts of cement, 50 parts of fly ash, 3 parts of plant fiber, 0.2 part of methyl cellulose, 2 parts of gypsum powder parts, 10 parts of fumed silica, and the plant fibers are selected from bagasse fibers.

Embodiment 2

[0038]In this embodiment, the mass parts of the upper fiber-reinforced cement slab 2 and the lower fiber-reinforced cement slab 3 are composed as follows: 100 parts of cement, 50 parts of fly ash, 3 parts of plant fiber, 0.2 part of methyl cellulose, 2 parts of gypsum powder parts, 10 parts of fumed silica.

[0039] Among them, the plant fiber is a mixture of bagasse fiber, bamboo fiber and hemp fiber, and its mass ratio is 1:2:1.2.

Embodiment 3

[0041] In this embodiment, the mass parts of the upper fiber-reinforced cement slab 2 and the lower fiber-reinforced cement slab 3 are composed as follows: 110 parts of cement, 55 parts of fly ash, 4 parts of plant fiber, 0.3 part of methyl cellulose, 2.5 parts of gypsum powder Parts, fumed silica 12 parts.

[0042] The plant fiber is a mixture of bagasse fiber, bamboo fiber and hemp fiber, the mass ratio of which is 1:2.1:1.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com