Aluminum alloy structure prefabricated building system and its assembly method

An aluminum alloy, prefabricated technology, applied in buildings, building components, building structures, etc., can solve the problems of difficult construction, low strength of joints, slow installation and construction speed, etc., to reduce construction waste and environmental pollution, safety High performance index and the effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

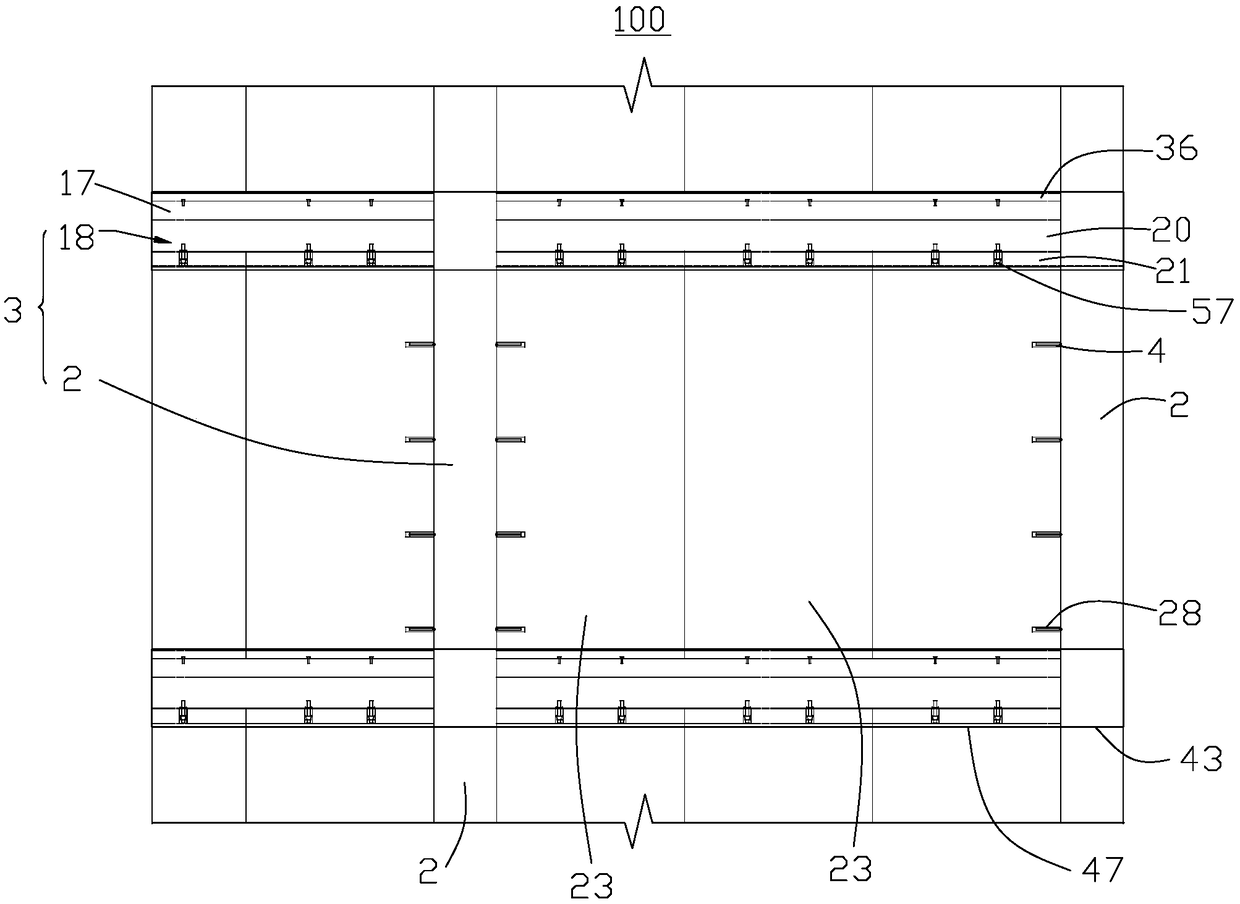

[0054] See also Figure 1 to Figure 4 , the first embodiment of the present invention provides an aluminum alloy structural prefabricated building system 100, including a prefabricated foundation 1, a structural support frame 3, several prefabricated floor slabs 17 and several wall panels (not shown).

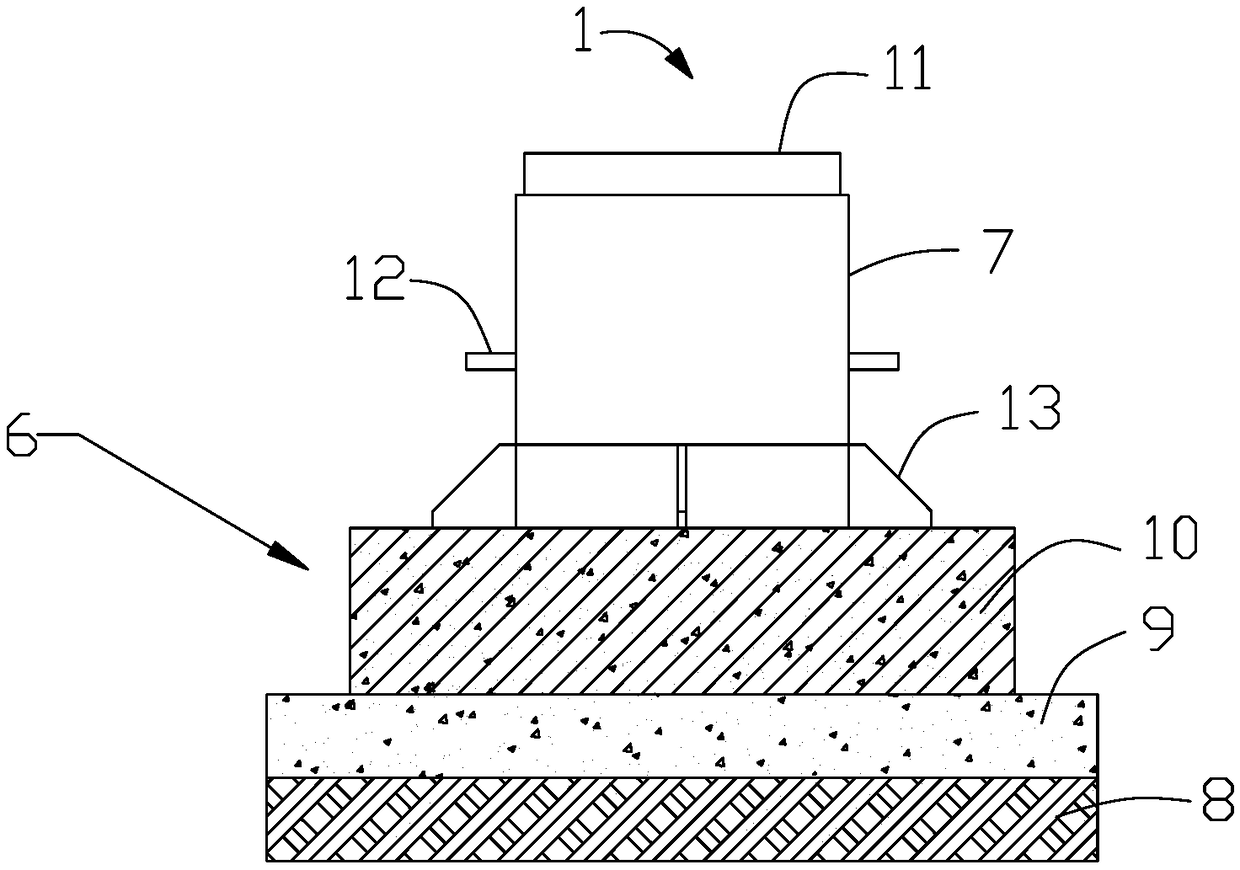

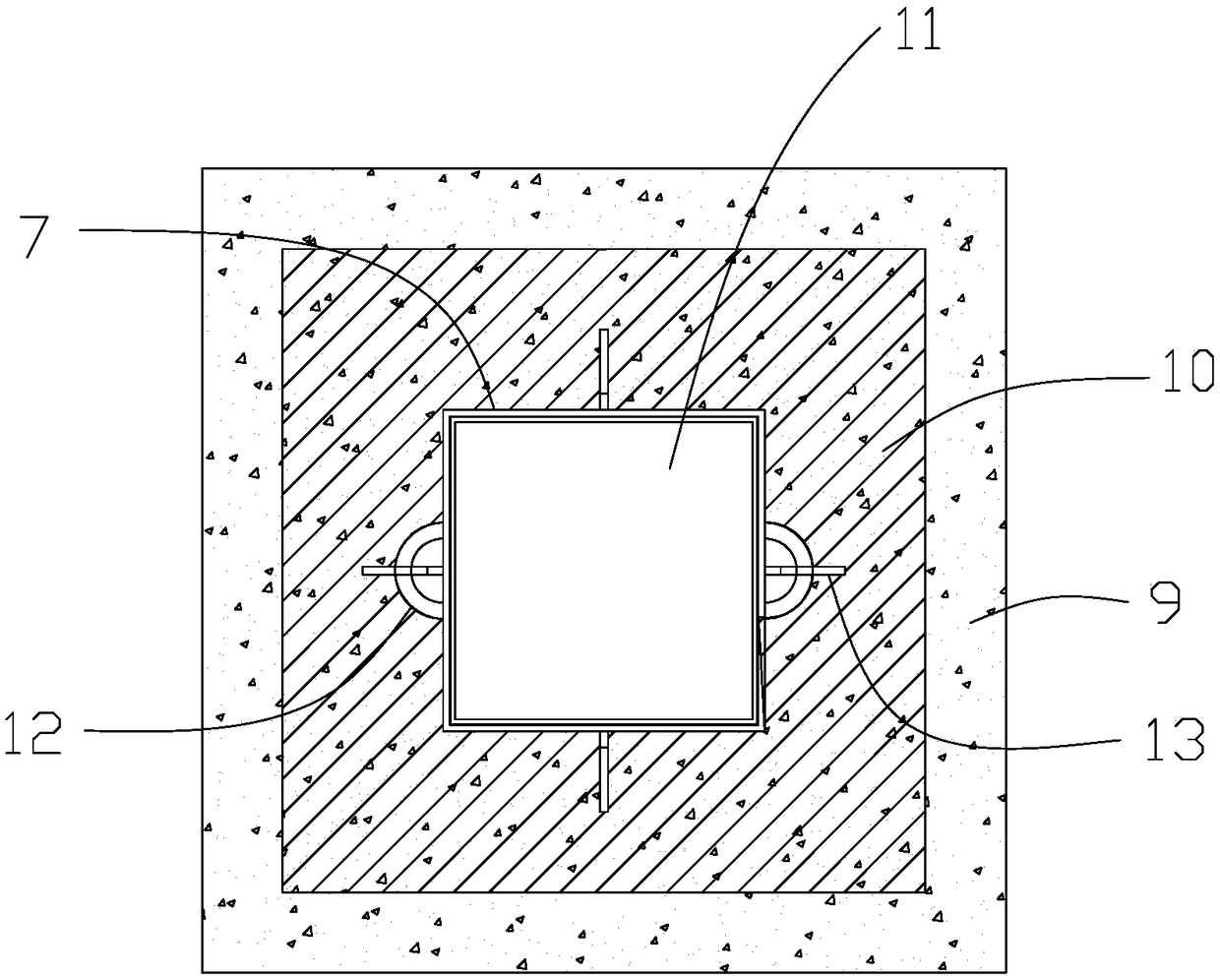

[0055] The prefabricated foundation 1 includes a base 6 and at least one aluminum alloy structural column 7 disposed on the base 6 . In this embodiment, each base 6 is provided with an aluminum alloy structural column 7 . The base 6 includes a first base layer 8, a second base layer 9 and a concrete column foundation 10, the second base layer 9 is connected to one side of the first base layer 8, and the concrete column base 10 is connected to the second base layer 9 facing away from The side of the first base layer 8 . In this embodiment, both the first base layer 8 and the second base layer 9 are made of concrete. The aluminum alloy structural column 7 is connected to the s...

Embodiment 1

[0092] 1. See Table 1 for raw material ratio; see Table 2 for stone tailings; see Table 3 for clay; see Table 4 for high-temperature flux; and see Table 4 for stabilizers: yttrium oxide and cerium oxide.

[0093] 2. Preparation:

[0094] The specific method of preparing the foamed lightweight wallboard from the above-mentioned proportioning raw materials includes the following steps:

[0095] S1. Ore washing: crush the stone tailings and pass through 1 mesh, then send the crushed stone tailings into the immersion pool. The high-pressure water pipe installed above the inner side of the feed port is sent into the stone tailings, and at the same time, the ammonium oxalate solution with a mass concentration of 1.5% is sprayed and wetted until the volume of the sprayed ammonium oxalate solution is 1.1 times the volume of the stone tailings After that, the spraying process can be stopped, soaked for 30 minutes, and the material is stirred every 5 minutes during the soaking period, ...

Embodiment 2

[0101] 1. See Table 1 for raw material ratio; see Table 2 for stone tailings; see Table 3 for clay; see Table 4 for high-temperature flux; and see Table 4 for stabilizers: yttrium oxide and cerium oxide.

[0102] 2. Preparation:

[0103] The specific method of preparing the foamed lightweight wallboard from the above-mentioned proportioning raw materials includes the following steps:

[0104] S1. Ore washing: crush the stone tailings and pass through 10 meshes, then send the crushed stone tailings into the immersion pool. The high-pressure water pipeline set above the inner side of the material port is sending the stone tailings into the stone tailings, and at the same time, the ammonium oxalate solution with a mass concentration of 5.5% is sprayed and wetted until the volume of the sprayed ammonium oxalate solution is 1.32 times the volume of the stone tailings After that, the spraying process can be stopped, soaked for 100 minutes, and the material is stirred every 5 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com