Heat source system service quality control system

A technology of quality control system and heat source system, applied in the field of heat energy supply system, can solve problems such as damage and inability to deal with emergencies in time, so as to improve the efficiency of operation and maintenance, improve the efficiency of maintenance and repair, and reduce the density of manual inspections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

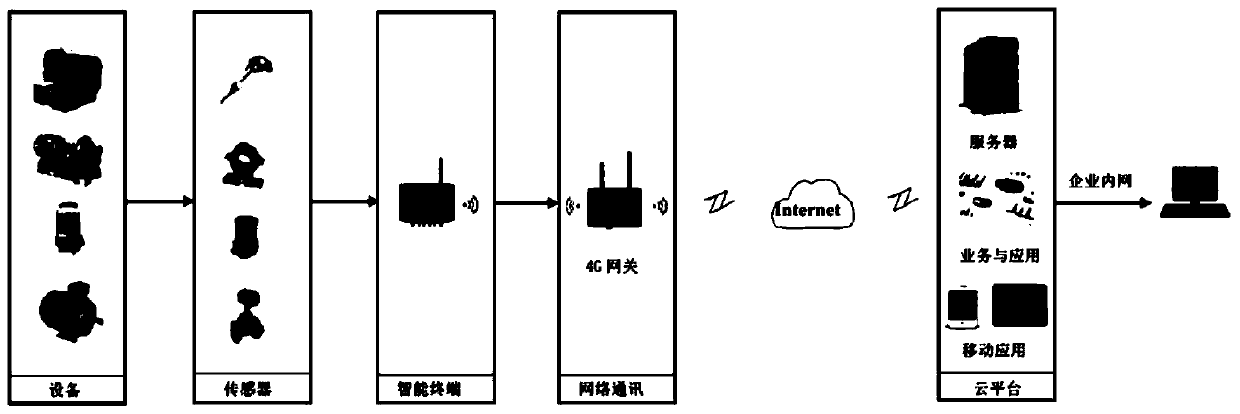

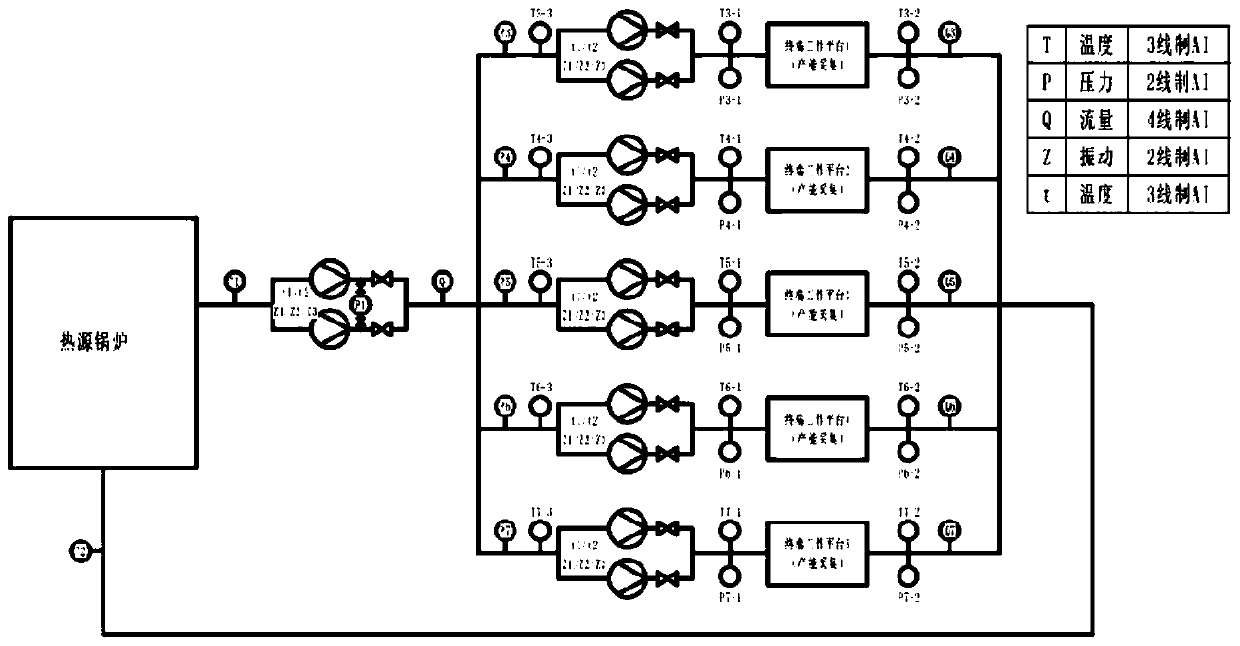

[0061] refer to figure 1 , this embodiment shows a heat source system service quality control system, including:

[0062] On-site equipment layer: on-site monitored equipment groups, including running motors and water pump units;

[0063] Sensor network: including pressure sensor, flow meter, liquid level gauge, thermal resistance (couple), temperature and humidity sensor, voltage and current sensor, vibration sensor, to detect the operating parameters of field equipment;

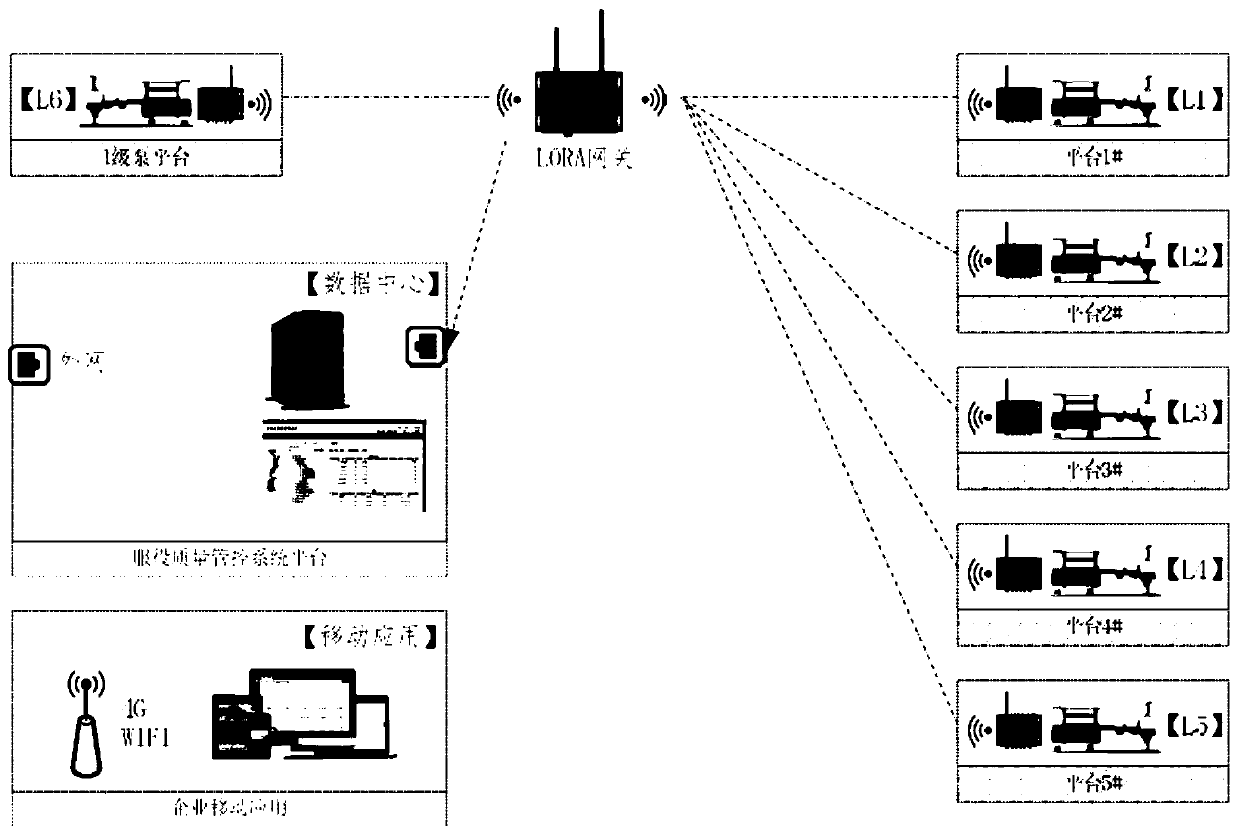

[0064] Intelligent terminal layer: As a field data slave station, it comes with a Lora wireless communication terminal, which is responsible for collecting sensor data connected to devices in the geographical area of the terminal and sending it to nearby Lora dual gateways through Lora wireless communication to complete the data push to the upper-level gateway;

[0065] Automation system interface: This interface is realized by the customer, and the SCADA data of the DCS system is collected and transmitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com