Diamond composite material and preparation method and application thereof

A technology of composite material and diamond, applied in the field of diamond composite material and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a preparation method of the diamond composite material described in the above technical solution, comprising the following steps:

[0041] Mixing water and a water-based adhesive to obtain a water-based adhesive solution;

[0042] Mixing inorganic composite binder, diamond abrasive grains, talcum powder, polycarboxylate superplasticizer and glass fiber to obtain a premix;

[0043] mixing the aqueous adhesive solution and the premix to obtain a slurry;

[0044] mixing the slurry with the foam to obtain a foam diamond composite slurry;

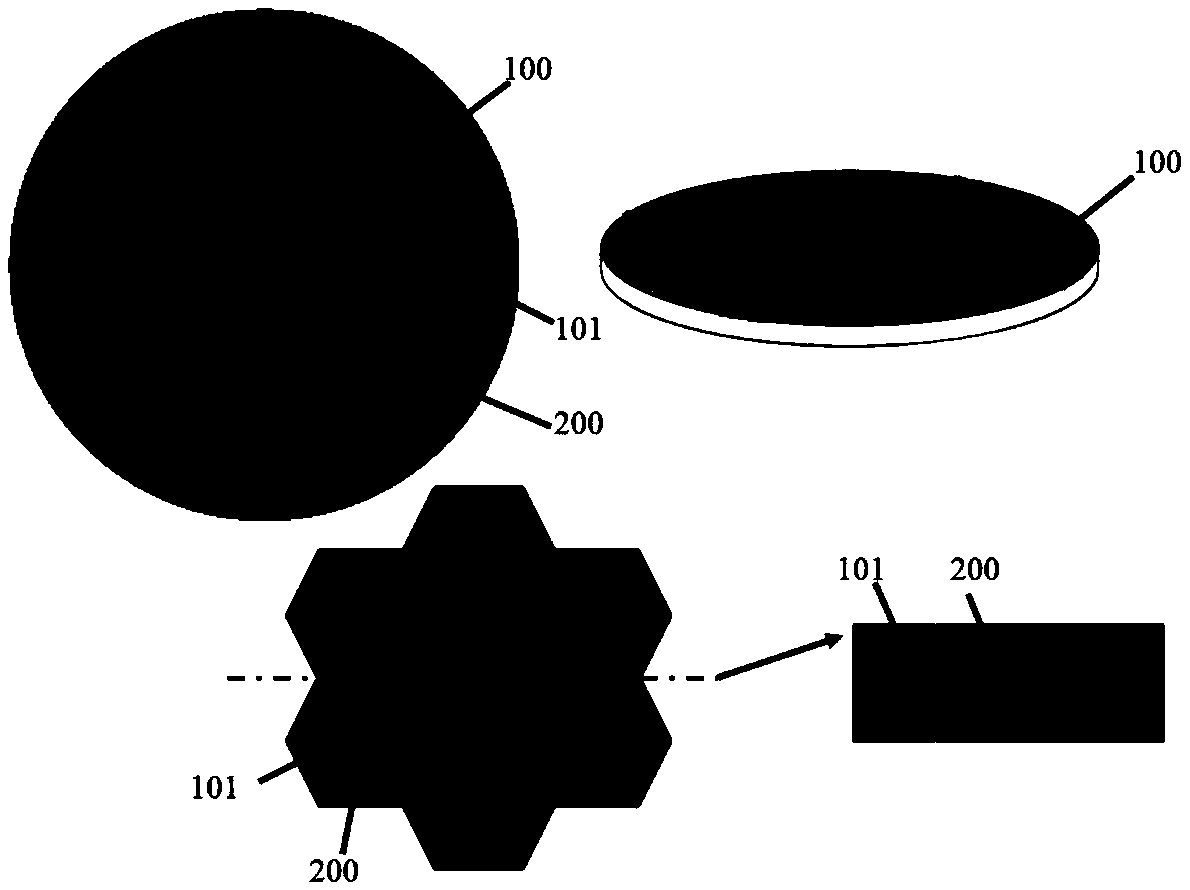

[0045] The foamed diamond composite slurry is poured into the holes of the honeycomb core material and baked to obtain the diamond composite material.

[0046] The invention mixes water and water-based adhesive to obtain a water-based adhesive solution.

[0047] The invention mixes inorganic composite binder, diamond abrasive grain, talcum powder, polycarboxylate water reducer and glass fiber to obta...

Embodiment 1

[0056] Weigh each component by weight percentage: gypsum hemihydrate 37%, silica fume 2%, diamond abrasive grain 3%, talcum powder 15%, polyvinyl alcohol solution 5% (concentration is 5%), foam 16%, glass fiber 0.5%, polycarboxylate superplasticizer 0.3%, water 21.2%;

[0057] Wherein, the foam is prepared as follows: prepare foaming agent aqueous solution, wherein the animal and plant foaming agent concentration is 10%, and the ratio of polyvinyl alcohol aqueous solution is 3%, then the foaming agent solution is sent to the foaming machine, and the density is prepared 50kg / m 3 the foam;

[0058] The particle size of the above-mentioned diamond abrasive grains is 0.5 μm;

[0059] Add water and polyvinyl alcohol solution into the stirring tank; premix the solid components of hemihydrate gypsum, silica fume, diamond abrasive grains, talcum powder, glass fiber, and polycarboxylate superplasticizer, and then stir Add the premixed mixture gradually to the stirring tank under cer...

Embodiment 2~8

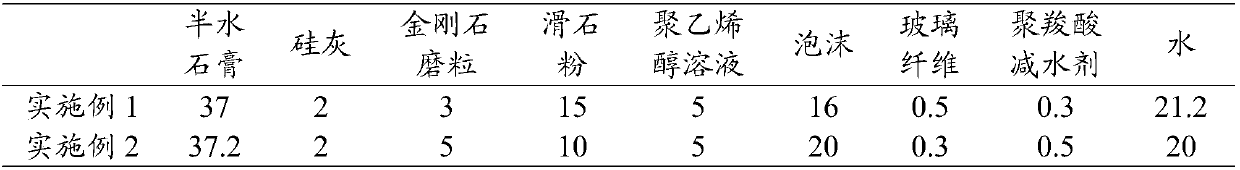

[0063] Embodiments 2-8 are comparative tests of 7 different formulations. These prescriptions are listed in Table 1 together with the prescription of embodiment 1, are all prepared by the processing step of embodiment 1.

[0064] Table 1. Diamond composite material weight percentage formula

[0065]

[0066]

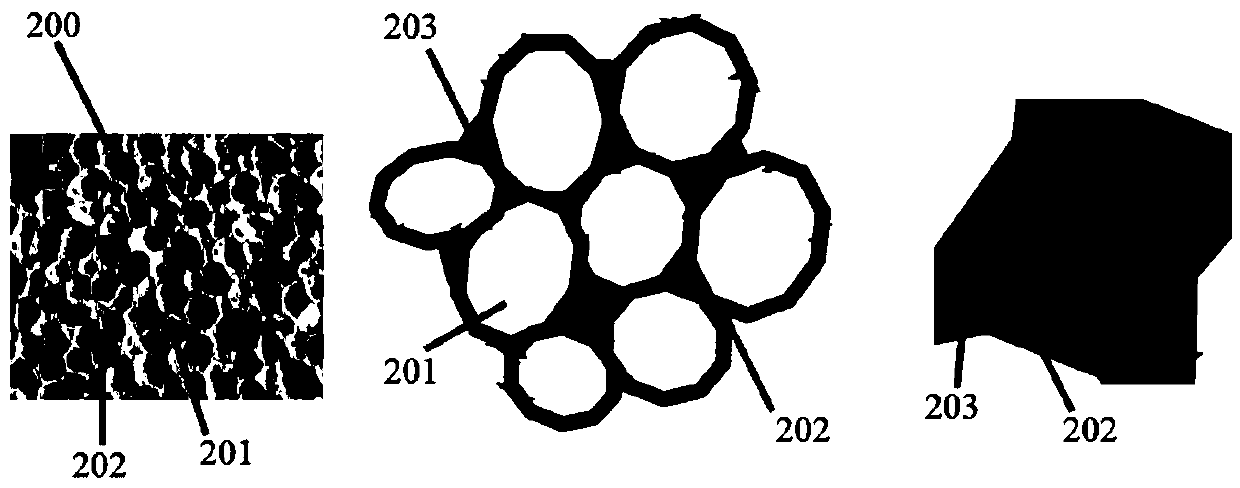

[0067] The diamond composite material provided by the invention can be used for precise grinding of flat hard and brittle materials, and when the hard and brittle materials are flat-machined, the hard and brittle materials are flat-pressed on a diamond flat plate and then ground with water. Such as figure 2 As shown, 200-water-soluble gypsum foam containing diamond abrasive grains; 201-air bubbles; 202-gypsum wall containing diamond abrasive grains; 203-diamond abrasive grains. Diamond composite foam abrasive blocks are composed of a large number of air bubbles, binders and diamond abrasive grains. When the diamond composite foam abrasive block will slightly di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com