Track type hose suitable for oil tank floating roof water drainage

A drainage hose and oil tank technology, applied in the field of drainage hose, can solve problems such as limited service life, difficult to effectively remove accumulated water, blockage of drainage channels, etc., achieve good tensile strength and tear strength, improve service life, The effect of improving drapability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

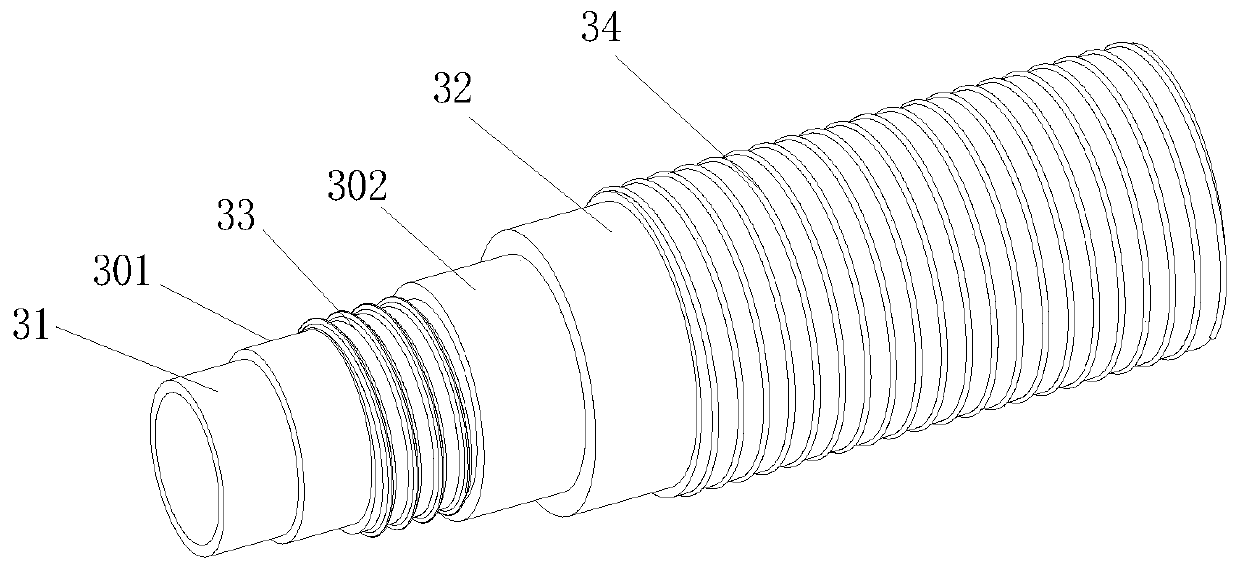

[0037] Embodiment 2: include necessary additives such as nitrile rubber 63kg, PVC resin 20-30kg, zinc oxide 3kg, aromatic hydrocarbon 5kg, stearic acid 2kg, kaolin 2kg, titanium dioxide 3kg, sulfur 2kg.

Embodiment 3

[0038] Embodiment 3: include necessary additives such as nitrile rubber 70kg, PVC resin 28kg, zinc oxide 3kg, aromatic hydrocarbon 4kg, stearic acid 3kg, kaolin 2kg, titanium dioxide 2kg, sulfur 1kg.

Embodiment 4

[0039] Embodiment 4: include necessary additives such as nitrile rubber 67kg, PVC resin 23kg, zinc oxide 4kg, aromatic hydrocarbon 6kg, stearic acid 3kg, kaolin 1kg, titanium dioxide 2kg, sulfur 1kg.

[0040] And obtain by following preparation method:

[0041] Wherein, the preparation steps of composite modified nitrile rubber are as follows:

[0042] S1. Mix nitrile rubber and PVC resin by weight, carry out masticating operation, and control the temperature to be 63-68°C;

[0043] S2, place the mixture after the mastication is completed in the open mill, and continue to add aromatic hydrocarbons, zinc oxide, stearic acid, kaolin in parts by weight, and control the temperature of the open mill to be 55-58 ° C, and the working hours are 2-3h, take out the material after mixing;

[0044] S3, adding weight parts of sulfur and titanium dioxide to the material after re-mixing for vulcanization treatment, time 1.2-1.5h, vulcanization treatment in S3 at a temperature of 140-148°C ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap