Efficient biological nitrogen removal process for sewage treatment

A technology for biological denitrification and sewage treatment, which is applied in biological water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc. It can solve the problem of difficult control, unstable operation performance and high energy consumption of biological denitrification process. and other problems, to achieve the effect of stable nitrification, optimization of biological community structure, and enhanced denitrification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be described in detail below in the form of specific embodiments.

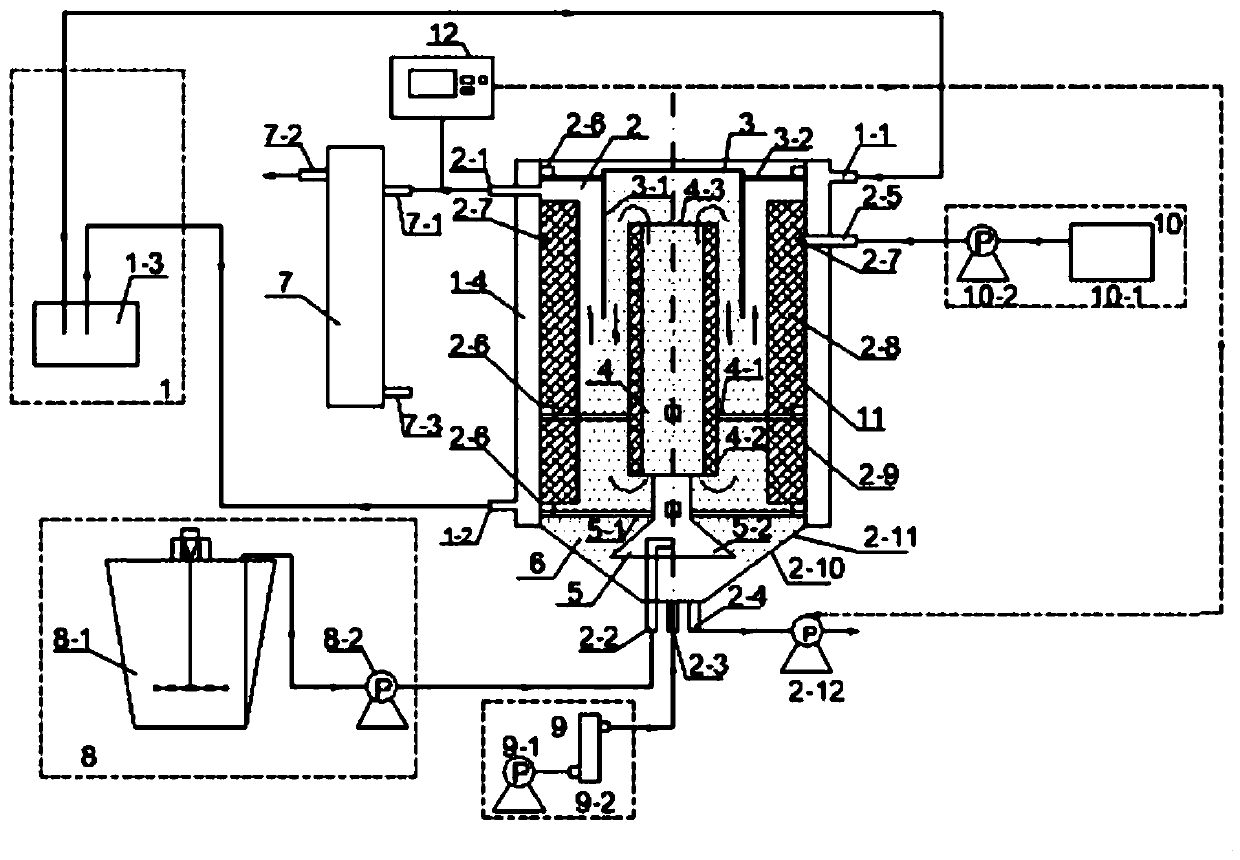

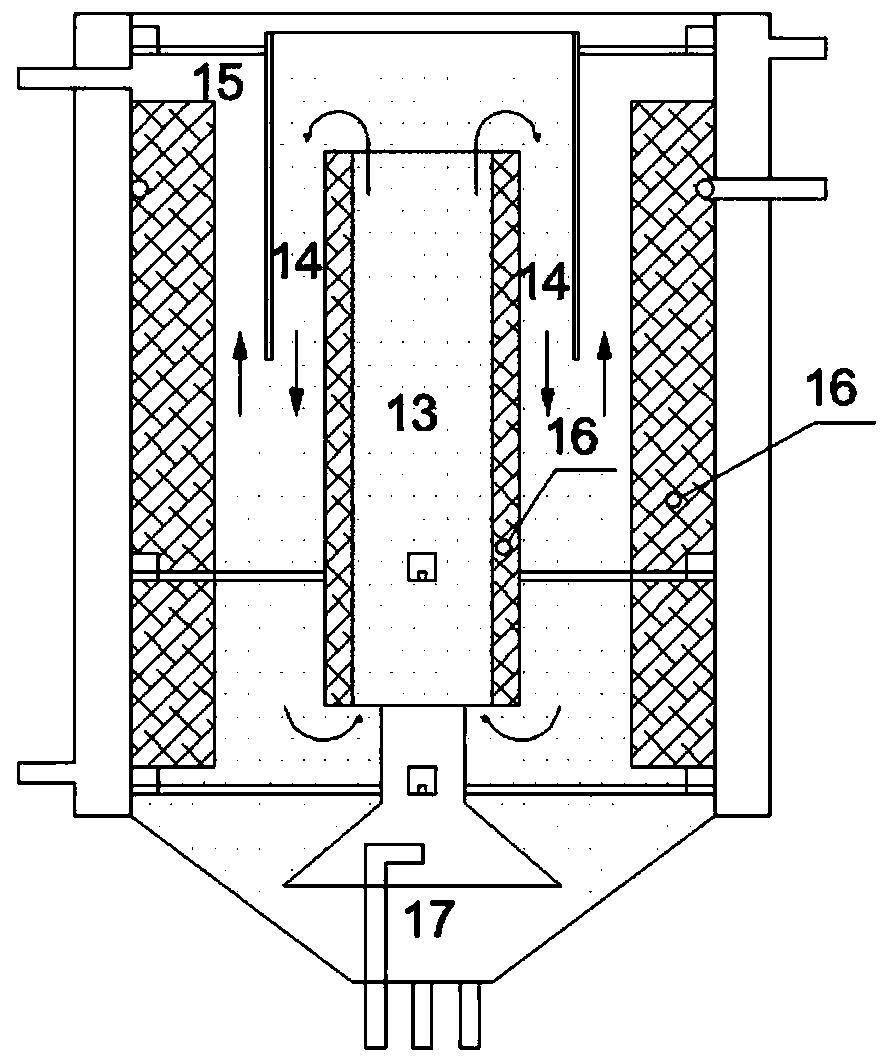

[0063] A high-efficiency biological denitrification process for sewage treatment mainly consists of a high-efficiency biological denitrification device main body (2), a sedimentation tank (7), a constant temperature system (1), a water inlet system (8), an aeration system (9), a chemical dosing system System (10) constitutes.

[0064] The constant temperature system (1) is composed of a constant temperature water bath layer (1-4), a constant temperature layer water inlet (1-1) (7 mm in diameter of the orifice) and a constant temperature layer water outlet (1-2) (7 mm in diameter of the orifice).

[0065] The said outer cylinder (2-11) consists of an upper cylinder (2-9) (290mm in height, 210mm in diameter) and a lower rounding platform (2-10) (210mm in diameter on the upper bottom surface, 50mm in diameter on the lower bottom surface, and 60mm in height); The upper cylinder (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com