Glycol modified petg polyester chip and its production process

A polyester chip and diol technology is applied in the field of diol modified PETG polyester chips and its production process, which can solve the problems of product color difference, high production cost, poor PETG polyester toughness, etc., and achieves easy access to raw materials. Obtain the effect of better product performance and better product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments provided by the present invention will be described in detail below with reference to the examples.

[0033] The terephthalic acid (PTA) used in the examples of the present invention was purchased from Jiangyin Hanbang Petrochemical Co., Ltd., neopentyl glycol (NPG) was purchased from Jihua BASF Co., Ltd., and diethylene glycol (DEG) was purchased from Saudi Petroleum Base Company , ethylene glycol (MEG) was purchased from Sabic Company, and catalyst ethylene glycol antimony was purchased from Liaoyang Synthetic Catalyst Co., Ltd.

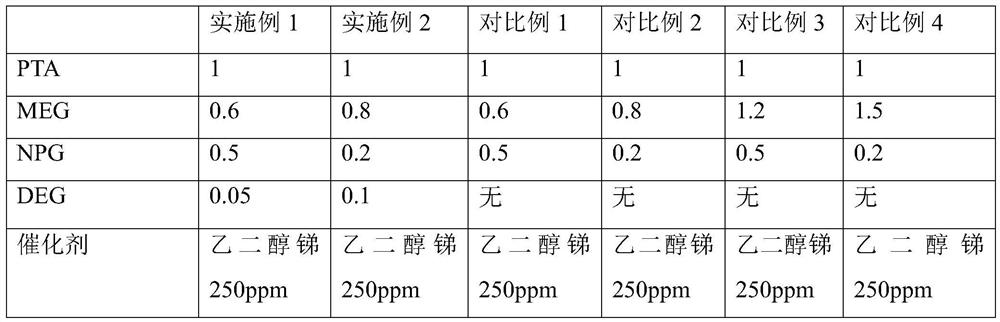

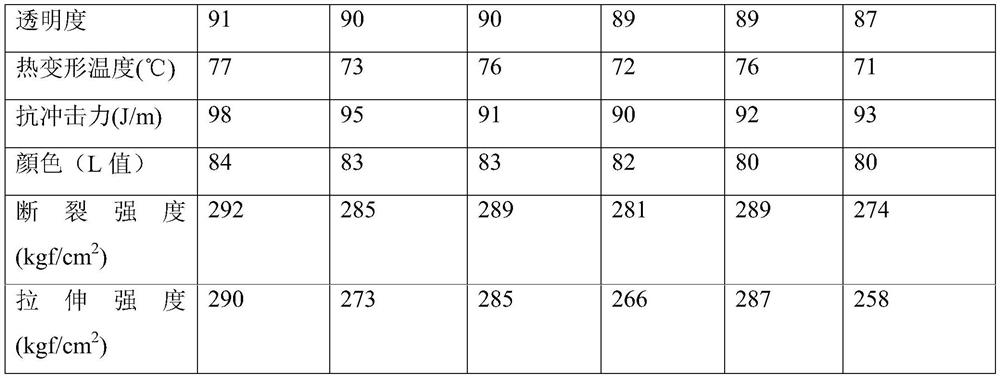

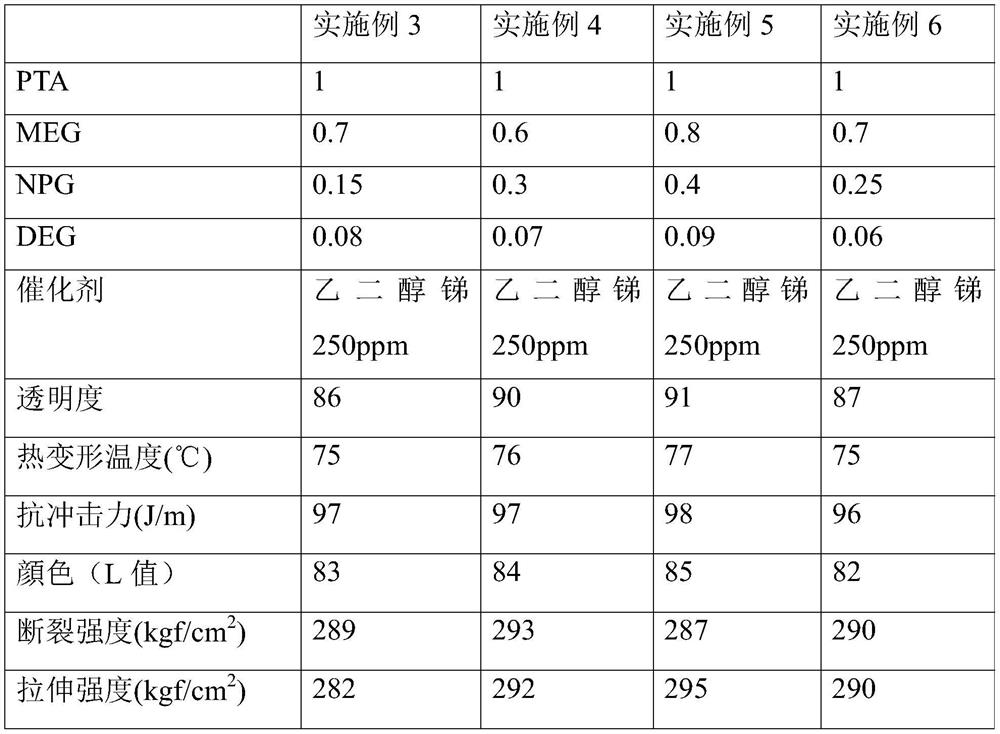

[0034] The raw material ratios of Examples 1 and 2 and Comparative Examples 1 to 4 are shown in Table 1:

[0035] Table 1 Slurry preparation (compounded according to the following molar ratio)

[0036] Example 1 Example 2 Comparative Example 1 Comparative Example 2 Comparative Example 3 Comparative Example 4 PTA 1 1 1 1 1 1 MEG 0.6 0.8 0.6 0.8 1.2 1.5 NPG 0.5 0.2 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com