A kind of 1500mpa grade cold forming strip steel and its production method

A production method and cold forming technology, applied in the field of metallurgy, can solve the problems of rising cost of auto parts and high cost of hot forming steel, and achieve the effects of improving plasticity, toughness, excellent welding and cold forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

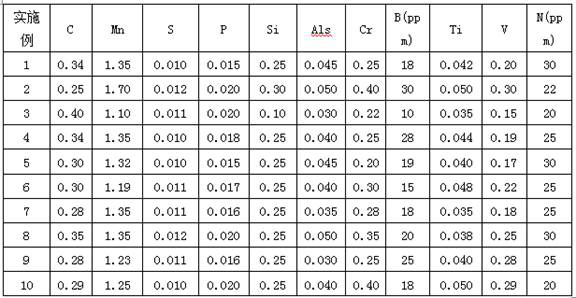

[0033] The thickness of the 1500MPa-grade cold-formed steel strip in this embodiment is 1.4mm, and its chemical composition and mass percentage are shown in Table 1.

[0034] The production method of the 1500MPa grade cold-formed steel strip of this embodiment includes molten iron pretreatment, converter steelmaking, LF furnace refining, RH refining, continuous casting, hot rolling, cold rolling, continuous annealing and smoothing process, and the specific process steps are as follows:

[0035](1) Hot metal pretreatment process: use composite injection Mg particles to reduce S in hot metal to 25ppm;

[0036] (2) Steelmaking process: 100 tons of top-bottom combined blowing converter is used, the end point control of the converter is: C: 0.024%, P: 0.009%; The phosphorus content of the finished product, the slag blocking method adopts the front and rear double gears, and adds medium-carbon ferromanganese, aluminum particles, low-carbon ferrochromium and ferromolybdenum during th...

Embodiment 2

[0047] The thickness of the 1500MPa-grade cold-formed steel strip in this embodiment is 0.8mm, and its chemical composition and mass percentage are shown in Table 1.

[0048] The production method of the 1500MPa grade cold-formed steel strip of this embodiment includes molten iron pretreatment, converter steelmaking, LF furnace refining, RH refining, continuous casting, hot rolling, cold rolling, continuous annealing and smoothing process, and the specific process steps are as follows:

[0049] (1) Hot metal pretreatment process: use composite injection Mg particles to reduce S in hot metal to 30ppm;

[0050] (2) Steelmaking process: 100-ton top-bottom re-blowing converter is used. The end point of the converter is controlled as follows: C: 0.022%, P: 0.008%; The phosphorus content of the finished product, the slag blocking method adopts the front and rear double gears, and adds medium-carbon ferromanganese, aluminum particles, low-carbon ferrochromium and ferromolybdenum duri...

Embodiment 3

[0061] The thickness of the 1500MPa-grade cold-formed steel strip in this embodiment is 1.5mm, and its chemical composition and mass percentage are shown in Table 1.

[0062] The production method of the 1500MPa grade cold-formed steel strip of this embodiment includes molten iron pretreatment, converter steelmaking, LF furnace refining, RH refining, continuous casting, hot rolling, cold rolling, continuous annealing and smoothing process, and the specific process steps are as follows:

[0063] (1) Hot metal pretreatment process: use composite injection Mg particles to reduce S in hot metal to 20ppm;

[0064] (2) Steelmaking process: 100 tons of top-bottom combined blowing converter is used, the end point control of the converter is: C: 0.035%, P: 0.009%; The phosphorus content of the finished product, the slag blocking method adopts the front and rear double gears, and adds medium-carbon ferromanganese, aluminum particles, low-carbon ferrochromium and ferromolybdenum during t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com