Iodine vapor generation and on-line detection recovery system for mandrel test

A technology of iodine vapor and mandrel, which is applied in the field of iodine vapor generation and online detection and recovery system, which can solve the problems of iodine particle blockage and iodine concentration cannot be measured accurately in real time, and achieve the effect of simple installation, high reliability and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

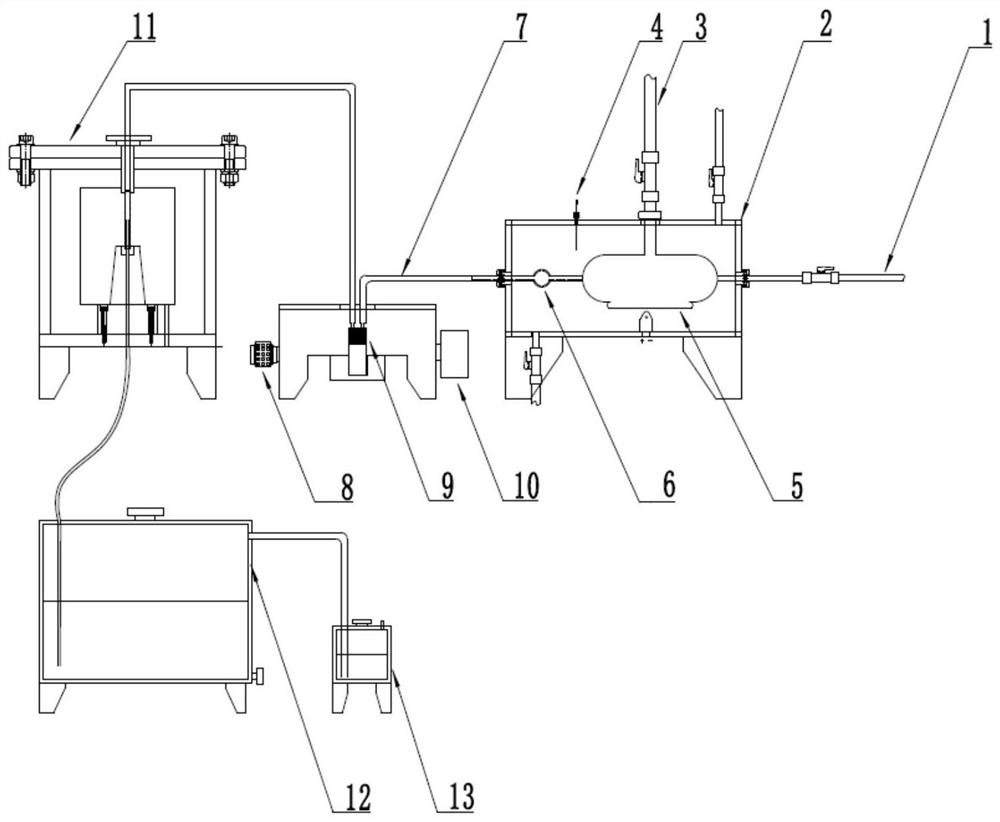

[0023] Such as figure 1 As shown, the present invention is an iodine vapor generation and on-line detection and recovery system for mandrel tests, comprising a constant temperature water tank 2, an elliptical chamber 5 located in the constant temperature water tank 2 and containing a negative angle groove, connected to a negative angle groove. The gas inlet pipe 1 of the elliptical chamber 5 of the groove is connected to the solid particle inlet pipe 3 of the elliptical chamber 5 containing the groove, and the thermocouple 4 located on the outer upper surface of the constant temperature water tank 2 is connected to the ellipse of the negative angle groove. The gas outlet pipe 7 of the shape chamber 5, the gas outlet pipe 7 is positioned at the front side of the constant temperature water tank 2 and has a section of circular visualization glass 6; The side li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com