Meat tenderizing agent and application method thereof

A technology of tenderizer and meat, which is applied in the direction of food science, etc., can solve the problems of complex energy consumption, etc., and achieve the effect of good tenderization effect, strong hydrolysis and easy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

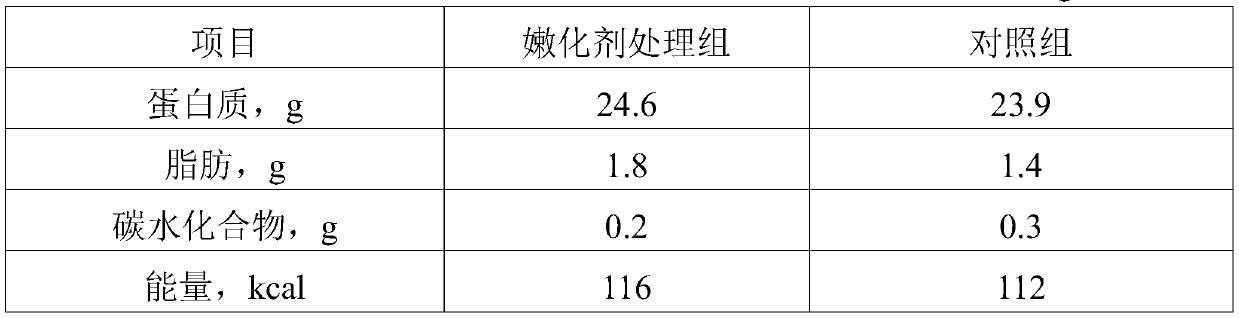

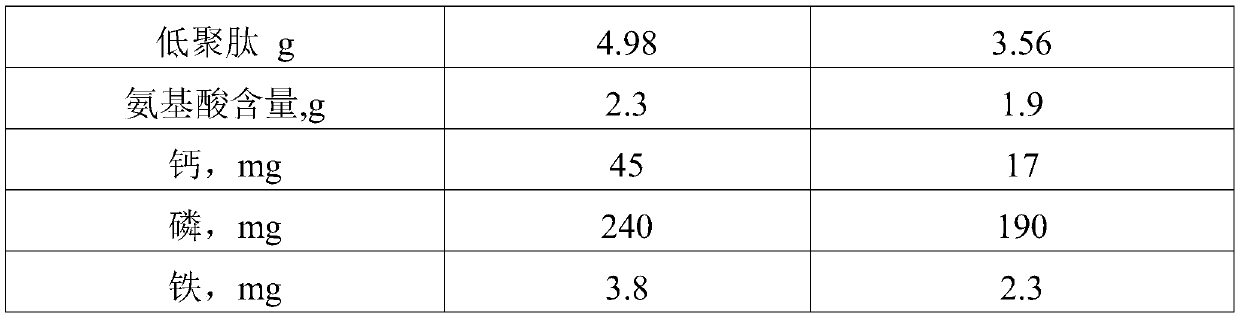

[0041] Chicken tender performance detection under the low temperature condition of embodiment 1

[0042] According to the parts by mass, 1 part of chicken tenderizing enzyme CMB-01, 1 part of edible salt, 2 parts of modified starch, 1 part of glucose and the rest are water to prepare the chicken tenderizer. Pre-cool the chicken tenderizer to 4°C, pour it into chicken thighs of 1.5×1.5×1.5cm, and completely submerge the meat with the tenderizer. After standing at 4°C for 16 hours, the tenderizer was removed by filtration. The tenderized chicken leg meat is heated in boiling water until the temperature of the meat center reaches above 75°C, under which condition the tenderizing enzyme is completely inactivated. After the treatment, the chicken is added with 3 parts by mass of conventional seasoning sauce, vacuum-sealed and packaged, and then sterilized at high temperature. Taste the tenderness of the chicken the next day, and the results of the sensory tasting show that after ...

Embodiment 2

[0050] Beef tenderization performance detection under the room temperature condition of embodiment 2

[0051] Get 3 parts of beef tenderizing enzyme CMB-02 by mass parts, 1 part of edible salt, 1 part of modified starch, 1 part of glucose, and the rest are water to be mixed with beef tenderizer, and beef tenderizer is mixed at 25 ℃ under room temperature (constant temperature) into 3.5 × 2 × 0.5 cm beef tendon meat, the tenderizer is completely submerged in the meat. After standing at 25°C for 1 hour, remove the tenderizer system by filtration, put the beef tendon into boiling water and continue heating until the temperature of the meat center reaches above 75°C, under which condition the tenderizing enzyme is completely inactivated. The processed beef is added in proportion to 4 parts of conventional seasoning sauce, vacuum-sealed and packaged, then sterilized at high temperature, and the tenderness of the beef is tasted the next day. The results of sensory tasting show that...

Embodiment 3

[0057] Pork tenderization performance detection under the high temperature condition of embodiment 3

[0058] Take 1 part of pork tenderizing enzyme CMB-03 in parts by mass, 2 parts of edible salt, 1 part of modified starch, 2 parts of glucose, and the rest are water to prepare pork tenderizer, and the pork tenderizer is preheated To 50 ℃, pour into 3.5×2×0.5cm pork knuckle meat, the tenderizer is completely submerged in the meat. After standing still at 50°C for 0.5h, filter out the tenderizer system, put the pork knuckle into boiling water and continue heating until the temperature of the meat center reaches above 75°C, under which condition the tenderizing enzyme is completely inactivated. The processed pork is added with 3 parts by mass of conventional seasoning sauce, vacuum-sealed and packaged, then sterilized at high temperature, and the tenderness of the pork is tasted the next day. The results of sensory tasting show that the tenderization effect of long time at low ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com