Casting system and method for frame

A pouring system and rack technology, which is applied to equipment for feeding molten metal into molds, casting molding equipment, molds, etc. Improve the complete pass rate and reduce the effect of scouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

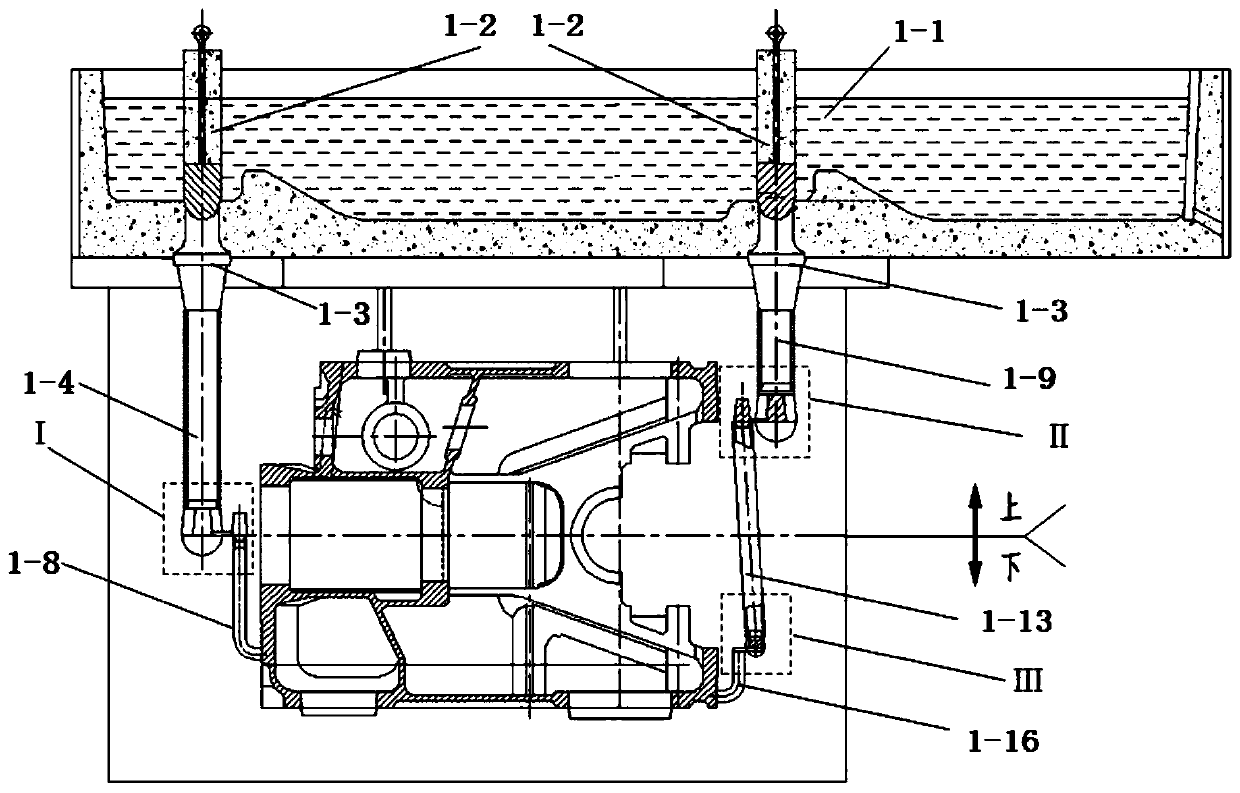

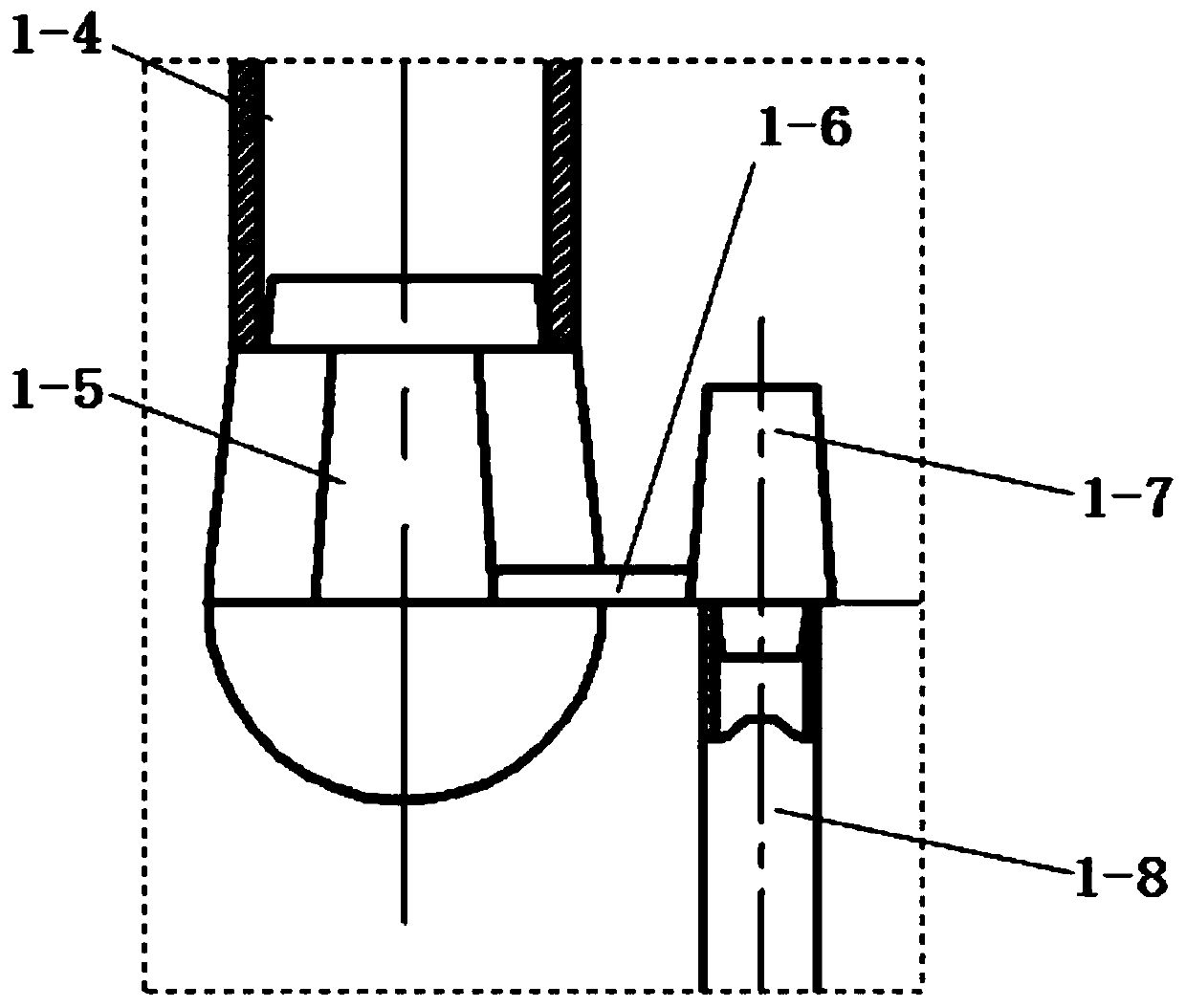

[0039] Such as figure 2 As shown, the gating system of the frame includes a first sprue 2, a first runner 3, two second sprues 4, two second runners 5, a plurality of filter units 6, a plurality of The inner runner 7, the first sprue 2 communicates with the upper part of the first runner 3, the lower part of the first runner 3 communicates with the two second runners 4 respectively, and the second sprue 4 communicates with the first runner 4. The upper part of the two runners 5 communicates, and each second runner 5 is provided with a filter unit 6 communicating with it, and the inrunner 7 communicates with the filter unit 6; during pouring, in the mold cavity, the exhaust side of the frame faces Down, the operating side faces up, the gating system is introduced from one side of the oil pan side, and the molten iron enters from the bottom of the cavity of the casting frame through the inrunner.

[0040] Wherein, the upper part of the first sprue 2 is also provided with a spru...

Embodiment 2

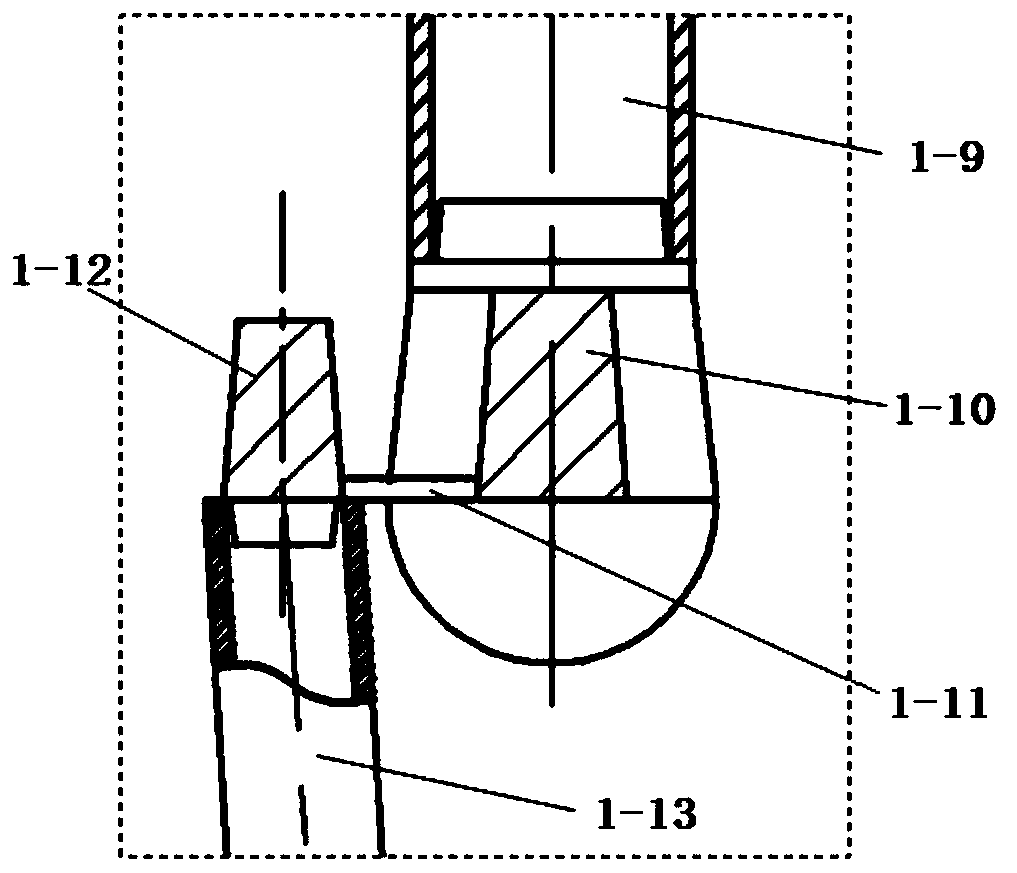

[0042] Such as image 3 As shown, the filter unit 6 in the present embodiment includes a filter cavity 61, the filter cavity 61 is provided with an inverted trapezoidal structure, and has the effect of gathering and collecting, and the filter sheet 62 is laterally fixed on the large mouth end of the filter cavity 61 for filtering from the first The pouring liquid of the second horizontal runner 5, the filter 61 is a foam ceramic filter, and the foam ceramic filter can choose silicon carbide, corundum and other different refractory materials and specifications according to the needs. In this embodiment, a square structure is adopted. Moreover, two adjacent filter chambers 61 share one filter sheet 62 , or separate filter sheets may be used respectively.

[0043] Wherein, the number of the filter unit 6 is the same as that of the inrunner 7, so as to ensure that the pouring liquid is all filtered.

[0044]In this embodiment, there are two second runners 5, and 16 filter units, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com