Preparation method of high-purity hydrogen chloride

A technology of hydrogen chloride and high-purity chlorine gas, which is applied in the direction of hydrogen chloride preparation, chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, etc., can solve the problems that cannot meet the use requirements of electronic grade chlorine gas, and achieve excellent adsorption of chlorine gas impurities, not easy to decompose and break, gas The effect of reducing the content of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

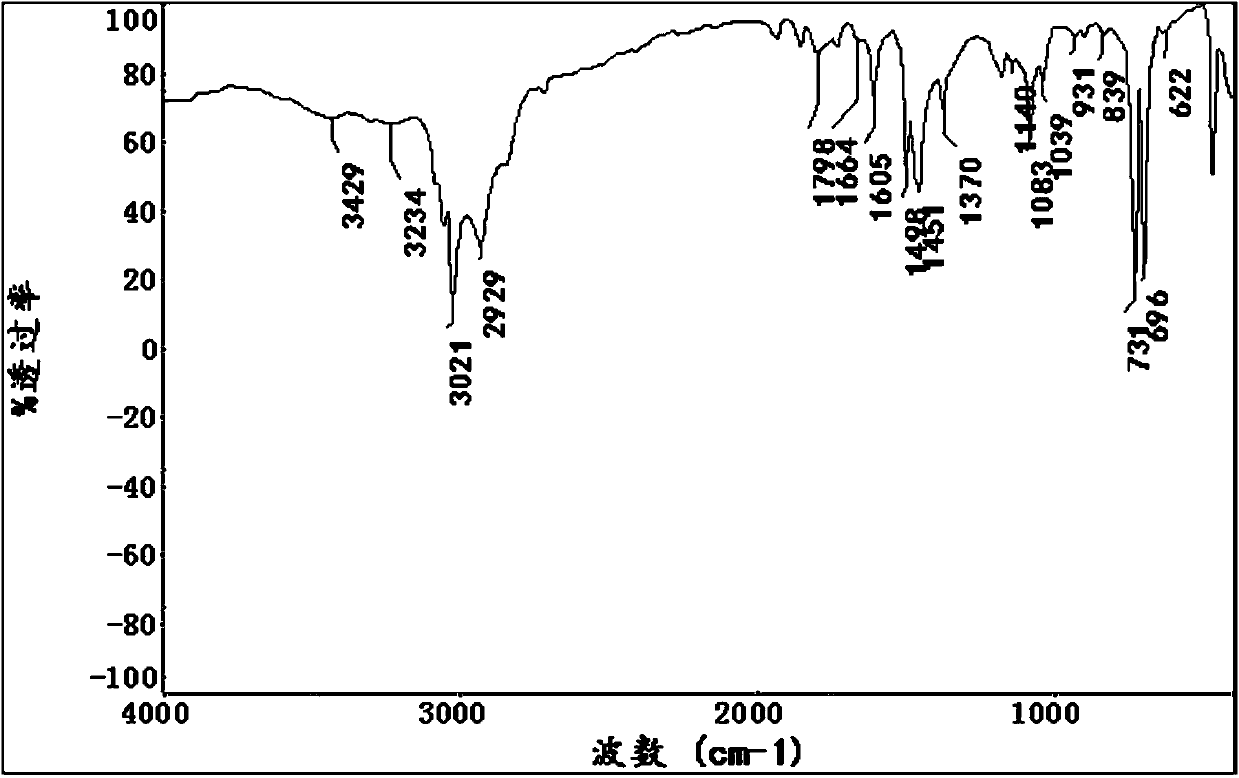

Image

Examples

Embodiment 1

[0023] A kind of preparation method of high-purity hydrogen chloride, its concrete scheme is as follows:

[0024] The high-purity chlorine and high-purity hydrogen are fed into the synthesis furnace according to the intake rate of 1:1.3 for synthesis reaction. The intake pressure of high-purity chlorine and high-purity hydrogen is the same as 1MPa, and the temperature in the synthesis furnace is controlled at 1080°C. The synthesized hydrogen chloride gas is cooled to room temperature through the cooling tower, and then enters the condensation tower, where the temperature is lowered to minus 90°C, hydrogen and other non-condensable gases are removed, and the crude product of liquefied hydrogen chloride gas is obtained; then re-gasified, and then enters Deep separation type gas purifier, the inlet operating pressure of the purifier is 1MPa, the temperature is 50°C, and the flow rate is 300 standard liters / minute; the above-mentioned high-purity hydrogen chloride is obtained; the ...

Embodiment 2

[0033] A kind of preparation method of high-purity hydrogen chloride, its concrete scheme is as follows:

[0034] The high-purity chlorine and high-purity hydrogen are fed into the synthesis furnace at an intake rate of 1:1.2 for synthesis reaction. The intake pressure of high-purity chlorine and high-purity hydrogen is the same as 0.1MPa, and the temperature in the synthesis furnace is controlled at 1000°C , the synthesized hydrogen chloride gas is cooled to room temperature through the cooling tower, and then enters the condensation tower, where the temperature is lowered to minus 80°C, hydrogen and other non-condensable gases are removed, and the crude product of liquefied hydrogen chloride gas is obtained; then gasified again, and finally Enter the deep separation type gas purifier, the inlet operating pressure of the purifier is 0.1MPa, the temperature is 20°C, and the flow rate is 100 standard liters / minute; the above-mentioned a kind of high-purity hydrogen chloride is o...

Embodiment 3

[0043] A kind of preparation method of high-purity hydrogen chloride, its concrete scheme is as follows:

[0044] The high-purity chlorine and high-purity hydrogen are fed into the synthesis furnace according to the intake rate of 1:1.5 for synthesis reaction. The intake pressure of high-purity chlorine and high-purity hydrogen is the same as 1.5MPa, and the temperature in the synthesis furnace is controlled at 1200°C , the synthesized hydrogen chloride gas is cooled to room temperature through the cooling tower, and then enters the condensation tower, where the temperature is lowered to minus 100°C, hydrogen and other non-condensable gases are removed, and the crude product of liquefied hydrogen chloride gas is obtained; then gasified again, and finally Enter the deep separation type gas purifier, the inlet operating pressure of the purifier is 10MPa, the temperature is 60°C, and the flow rate is 400 standard liters / minute; the above-mentioned a kind of high-purity hydrogen ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com