Device for removing fluorides and recovering carbon from waste cathode carbon block of aluminum electrolysis cell and method of device for removing fluorides and recovering carbon from waste cathode carbon block of aluminum electrolysis cell

A technology of waste cathode carbon block and aluminum electrolytic cell, which is applied in the direction of preparation/purification of alkali metal fluoride and carbon, etc. It can solve the problem that waste cathode carbon cannot be effectively and harmlessly utilized, and achieves low recycling cost and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

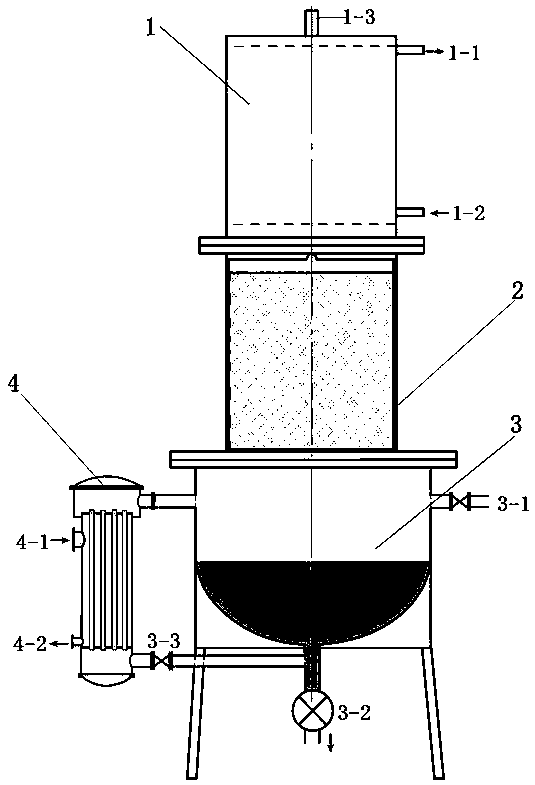

[0038] Such as Figures 1 to 2 As shown, the device for defluorinating and recovering carbon from the spent cathode carbon blocks of aluminum electrolytic cells includes an upper gas condenser 1, a washing chamber 2 in the middle that is detachably connected to the gas condenser 1, and a lower part that is connected to the The evaporation chamber 3 connected to the washing chamber 2, and the heat exchange chamber 4 that provides water vapor and heat to the evaporation chamber 3, and a hanging basket is placed inside the washing chamber 2.

[0039] The bottom of the gas condenser 1 is flanged and communicated with the top of the washing chamber 2, the top of the gas condenser 1 is provided with a gas outlet 1-3, the lower part of the gas condenser 1 is provided with a condensed water inlet 1-2 and the upper part is provided with a condensate The water outlet 1-1; the side of the evaporation chamber 3 is provided with an air pipe, the air pipe is provided with an air valve 3-1, ...

Embodiment 2

[0048] Such as Figures 1 to 2 As shown, the device for defluorinating and recovering carbon from the spent cathode carbon blocks of aluminum electrolytic cells includes an upper gas condenser 1, a washing chamber 2 in the middle that is detachably connected to the gas condenser 1, and a lower part that is connected to the The evaporation chamber 3 connected to the washing chamber 2, and the heat exchange chamber 4 that provides water vapor and heat to the evaporation chamber 3, and a hanging basket is placed inside the washing chamber 2.

[0049] The bottom of the gas condenser 1 is flanged and communicated with the top of the washing chamber 2, the top of the gas condenser 1 is provided with a gas outlet 1-3, the lower part of the gas condenser 1 is provided with a condensed water inlet 1-2 and the upper part is provided with a condensate The water outlet 1-1; the side of the evaporation chamber 3 is provided with an air pipe, the air pipe is provided with an air valve 3-1, ...

Embodiment 3

[0058] Such as Figures 1 to 2 As shown, the device for defluorinating and recovering carbon from the spent cathode carbon blocks of aluminum electrolytic cells includes an upper gas condenser 1, a washing chamber 2 in the middle that is detachably connected to the gas condenser 1, and a lower part that is connected to the The evaporation chamber 3 connected to the washing chamber 2, and the heat exchange chamber 4 that provides water vapor and heat to the evaporation chamber 3, and a hanging basket is placed inside the washing chamber 2.

[0059] The bottom of the gas condenser 1 is flanged and communicated with the top of the washing chamber 2, the top of the gas condenser 1 is provided with a gas outlet 1-3, the lower part of the gas condenser 1 is provided with a condensed water inlet 1-2 and the upper part is provided with a condensate The water outlet 1-1; the side of the evaporation chamber 3 is provided with an air pipe, the air pipe is provided with an air valve 3-1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com