MOFs (metal organic frameworks) material for cigarette filter and preparation method and application of MOFs material

A technology for filters and cigarettes, which is applied in applications, e-liquid filter elements, separation methods, etc. It can solve the problems of affecting the flavor and taste of cigarettes and low efficiency, and achieve adjustable light irradiation intensity, less damage, and mild light irradiation intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

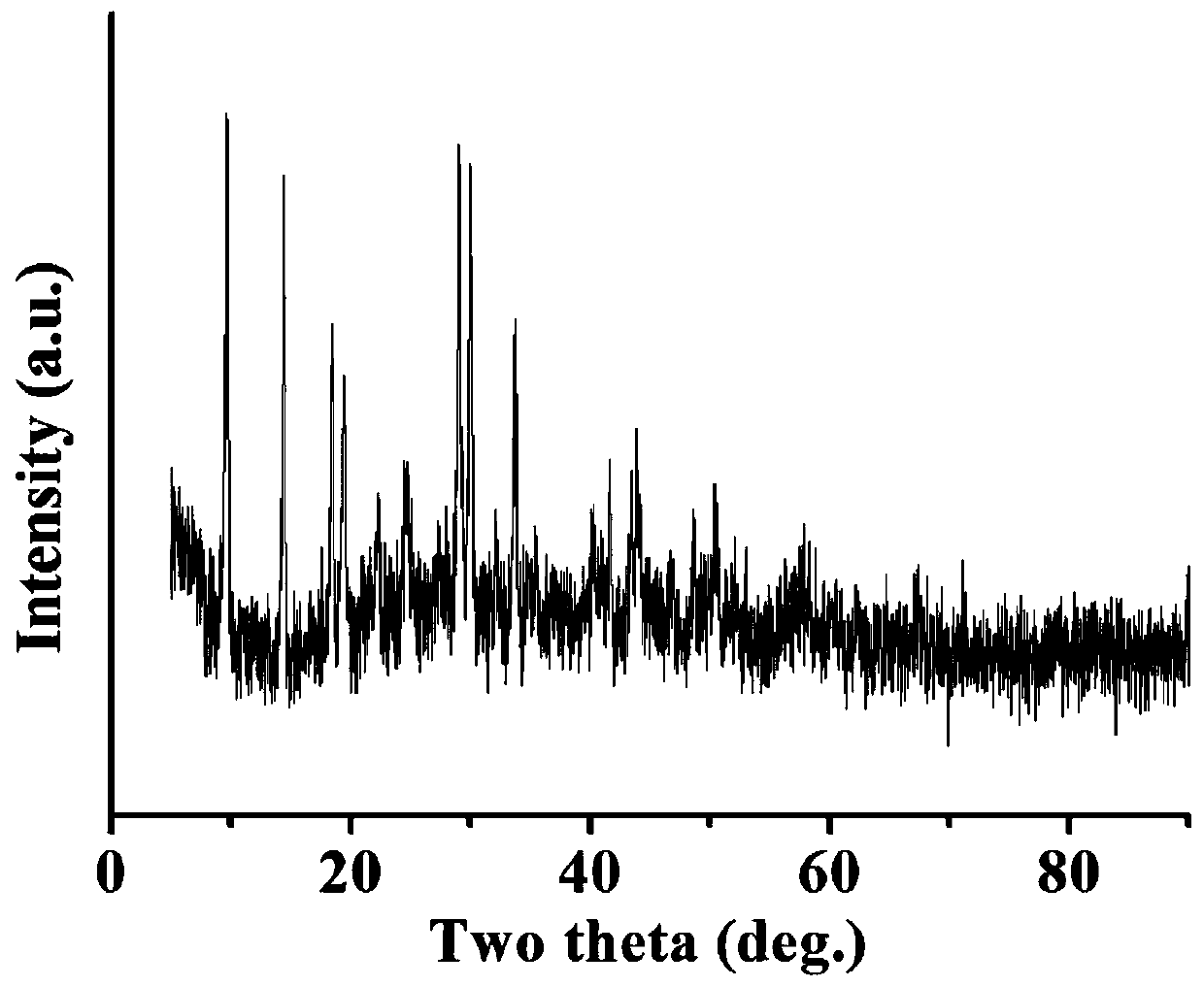

[0039] In this embodiment, the MOFs material PTA-Fe used for cigarette filters was synthesized according to the following steps:

[0040] (1) Under stirring conditions, add 220mL DMF, 0.2mol terephthalic acid and 0.1mol Fe(OH) to the reactor at a uniform rate. 2 , The total feeding time is 10min, and after the feeding is completed, continue to stir until uniform, the stirring speed is 300r / min, and the stirring time is 30min;

[0041] Continue to add activator hydrochloric acid to the reactor under stirring conditions for 10 minutes to obtain a mixed reaction liquid;

[0042] (2) Perform light irradiation on the mixed reaction solution, the light irradiation intensity is 365nm, the light irradiation time is 10h, and then cooled to room temperature, the resulting product is centrifuged to obtain a solid product;

[0043] (3) The solid product is subjected to solvent removal treatment in the air at a temperature of 180° C. and a time of 2 hours to obtain a solid powdery target product fo...

Embodiment 2

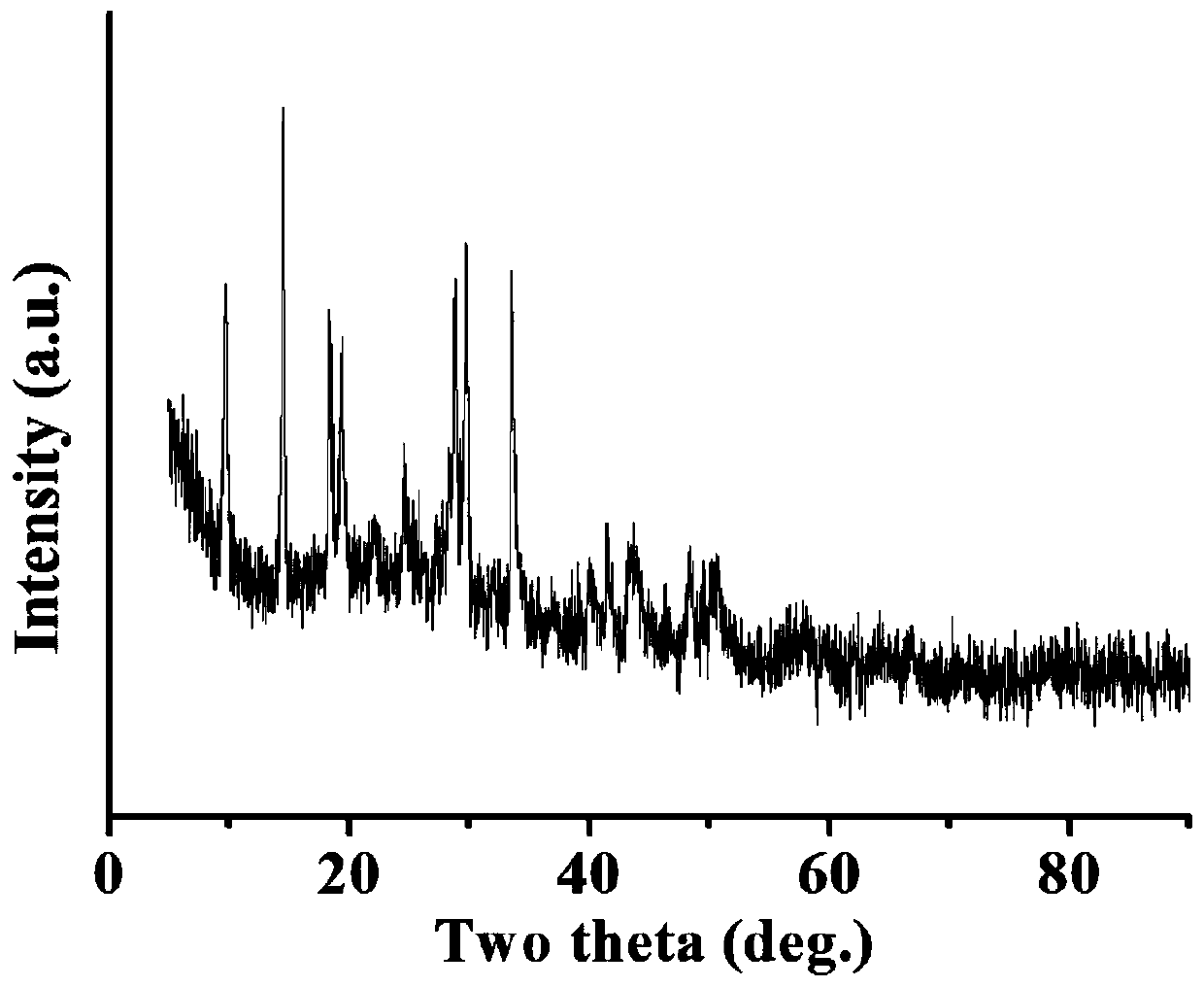

[0046] In this example, the MOFs material PTA-Mn for cigarette filters was synthesized according to the following steps:

[0047] (1) Under stirring conditions, add 200mL DMF, 0.21mol terephthalic acid and 0.1mol Mn(OH) to the reactor at a uniform rate. 2 , The total feeding time is 5min, and after the feeding is completed, continue to stir until uniform, the stirring speed is 200r / min, and the stirring time is 20min;

[0048] Continue to add the activator pyruvic acid to the reactor under stirring conditions for 60 min to obtain a mixed reaction liquid;

[0049] (2) Perform light irradiation on the mixed reaction solution, the light irradiation intensity is 420nm, the light irradiation time is 12h, and then cooled to room temperature, the resultant product is centrifuged to obtain a solid product;

[0050] (3) The solid product is subjected to solvent removal treatment in air at a temperature of 220° C. and a time of 3 hours to obtain a solid powdery target product for use in the MOFs...

Embodiment 3

[0053] In this example, the MOFs material PTA-Zn used for cigarette filters was synthesized according to the following steps:

[0054] (1) Under stirring conditions, add 160mL DMF, 0.11mol terephthalic acid and 0.05mol ZnO to the reactor in sequence at a uniform rate. The total feeding time is 5min. After the feeding is completed, continue to stir until uniform, the stirring speed is 260r / min, stirring time is 12min;

[0055] Continue to add nitric acid, an activator, to the reactor under stirring conditions for 20 minutes to obtain a mixed reaction liquid;

[0056] (2) Perform light irradiation on the mixed reaction solution, the light irradiation intensity is 450nm, the light irradiation time is 20h, and then cooled to room temperature, the resultant product is centrifuged to obtain a solid product;

[0057] (3) The solid product is subjected to solvent removal treatment in the air at a temperature of 240° C. and a time of 3 hours to obtain a solid powdery target product for use in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com