Method for producing pingyangmycin by fermentation

A technology of pingyangmycin and fermentation products, applied in the field of fermentation engineering, can solve the problems of unstable fermentation production level, large workload and little effect, and achieve the effects of improving industrial fermentation level, production level and output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

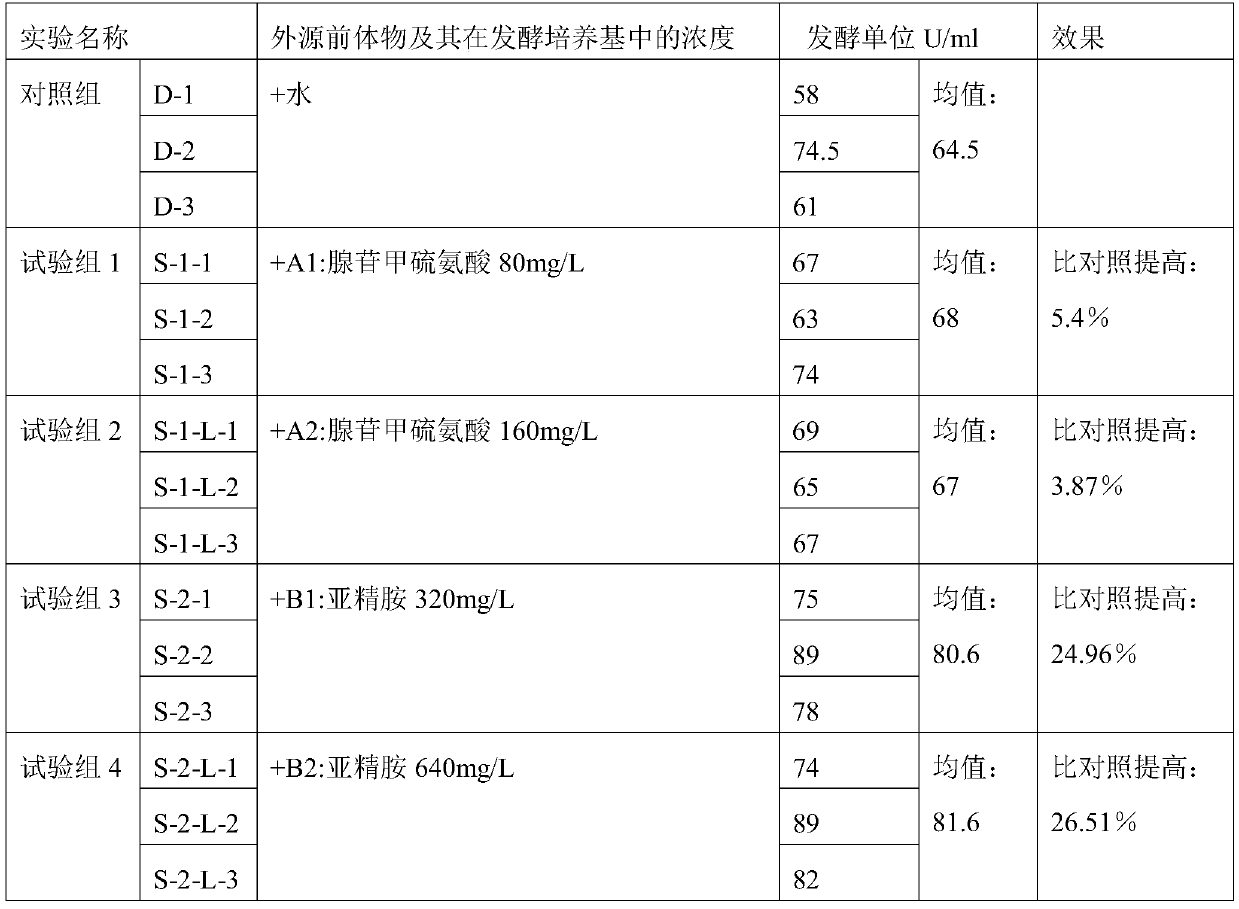

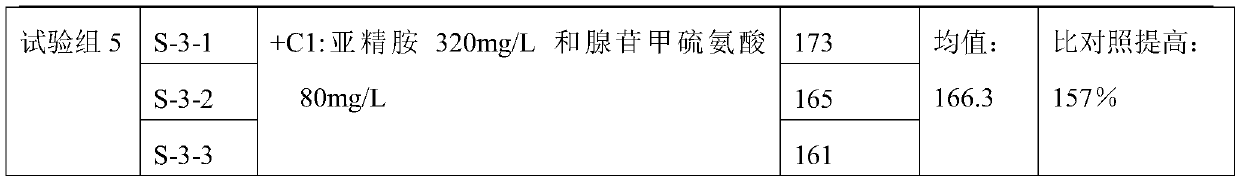

[0038] Example 1: Shake flask pingyangmycin fermentation precursor comparison

[0039] The culture of the strain is activated, the cell is expanded, and finally the seed solution of Streptomyces verticillium (product of Beina Industrial Microbial Library, code BNCC215870) is transferred to the fermentation medium for fermentation to produce pingyangmycin. This example is divided into For the control group, the test group 1, the test group 2, the test group 3, the test group 4, and the test group 5, three repetitions are set for each group, that is, the control group is D-1, D-2 and D-3, and the test group 1 is Sl-1, S-1-2 and S-1-3, test group 2 is S-1-L-1, S-1-L-2 and S-1-L-3, test group 3 is S- 2-1, S-2-2 and S-2-3, test group 4 is S-2-L-1, S-2-L-2 and S-2-L-3, test group 5 is S- 3-1, S-3-2 and S-3-3, the final test results are averaged.

[0040] 1. Preparation of precursor solution and fermentation medium:

[0041] Configuration A1: 2.4mg / ml adenosylmethionine solution; A2: 4.8...

Embodiment 2

[0049] Example 2 Determination of the addition ratio of exogenous precursors and the fermentation unit (titer) of the target product of pingyangmycin produced by the fermentation of Streptomyces verticillium by carbon source and nitrogen source

[0050] 1. The orthogonal experiment was used to test the interaction of the ratio of exogenous precursors and the carbon source and nitrogen source in the fermentation. Among them, the concentration of adenosylmethionine in the fermentation medium, spermidine The concentration in the fermentation medium, the mass percentage of maltose in the fermentation medium, and the mass percentage of soy peptone in the fermentation medium are respectively set at three levels, as shown in Table 2.

[0051] Among them, the fermentation medium is prepared: the fermentation medium is configured according to the ratio of maltose and soy peptone in the fermentation medium as described in Table 2, and the mass percentages of other components are starch 3.0%, ...

Embodiment 3

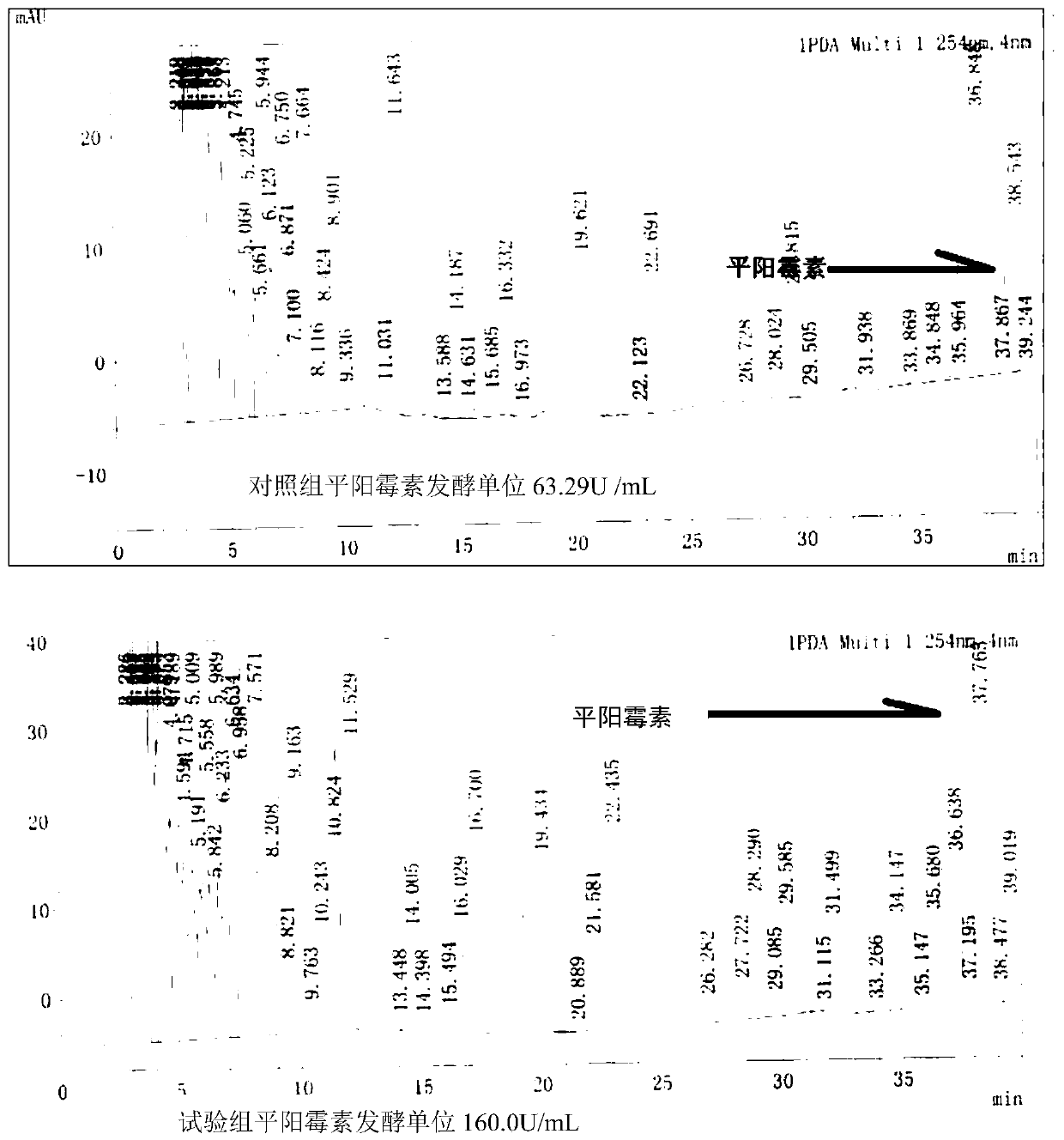

[0060] Example 3 Shaking flask to produce pingyangmycin

[0061] Activate the culture, expand the culture, and finally inoculate the seed solution of Streptomyces verticillium (product of Beina Industrial Microbiology Bank, code BNCC215870) into the fermentation medium for fermentation to produce Pingyangmycin, the control group and the test group Set up three repetitions, that is, the control group is CG-1, CG-2 and CG-3, and the test group is EG-1, EG-2 and EG-3. The final test results are averaged. The specific test steps are as follows:

[0062] 1. Preparation of exogenous precursor solution and fermentation medium:

[0063] Configure a composite solution of 2.4mg / ml adenosylmethionine solution + 9.6mg / ml spermidine solution: take 0.24g of adenosylmethionine and 0.96g of spermidine, dissolve it with sterile purified water, Dilute the purified water to 100ml of water to obtain a composite solution. The prepared composite solution is sterilized and filtered with a sterile filter m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com