Manufacturing method of dual-power output energy taking magnetic core

A manufacturing method and dual-power technology, applied in the field of electricity, can solve problems such as poor stability, complex design of energy-taking magnetic core parameters, inaccurate energy-taking magnetic core output power, etc., to reduce the operation failure rate and reduce the workload of later maintenance , The effect of saving circuit space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

[0030] A method for manufacturing a dual-power output energy-taking magnetic core, specifically comprising the following steps:

[0031] A. Obtain the grid environment parameters and determine the magnetic core limit: bus current I 1 =3A, grid frequency f=50Hz, output power P 1 =0.03W when the secondary filter circuit voltage U C1 =1.2V, output power P 2 =0.05W, the secondary filter circuit voltage, U C2 = 1.5V.

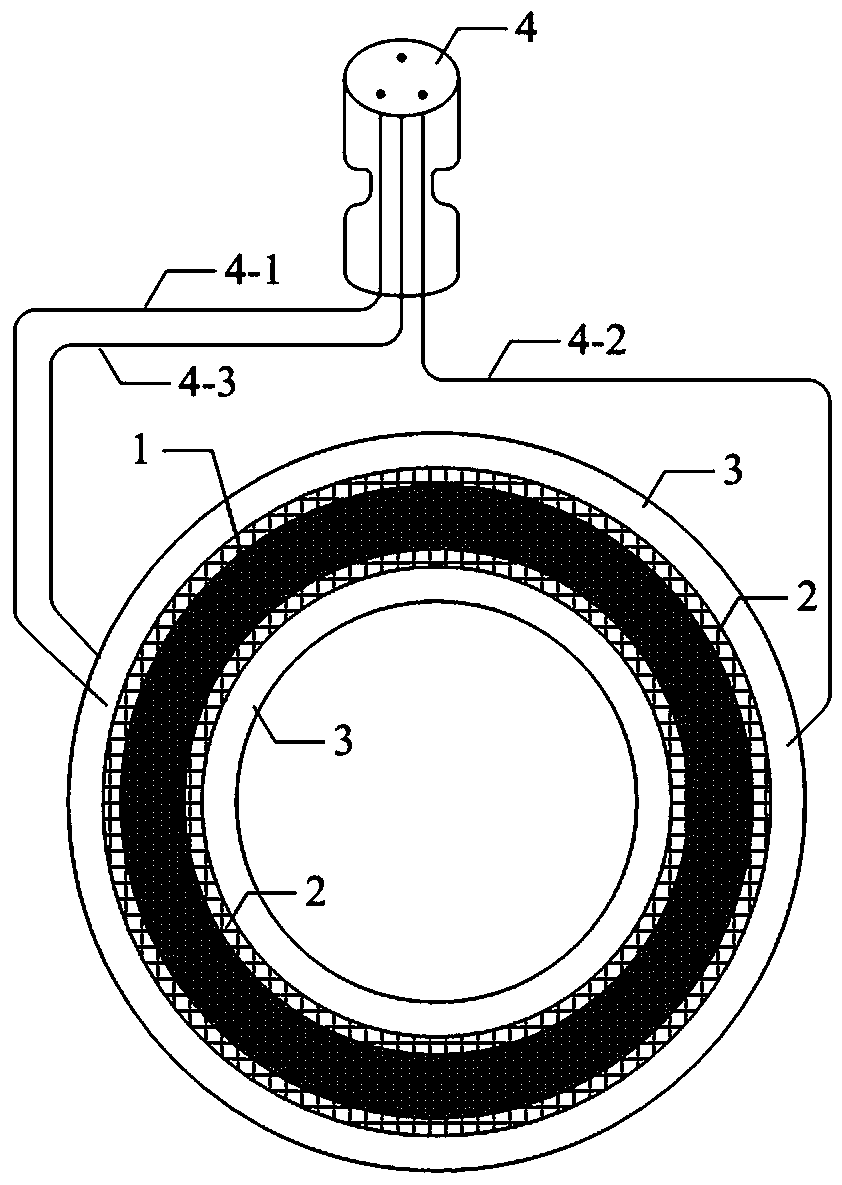

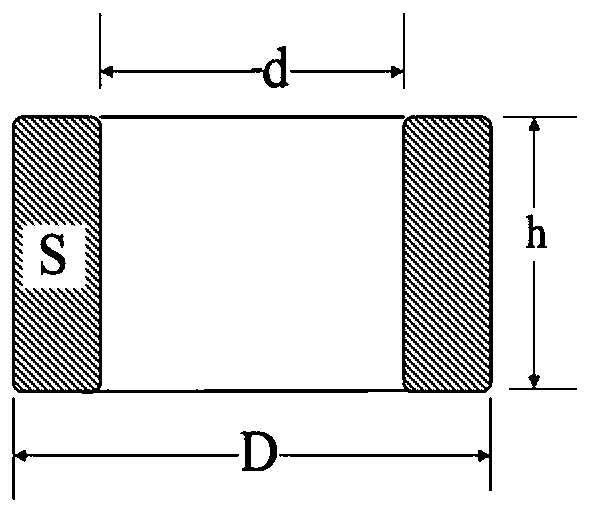

[0032] The energy-taking magnetic core selects the toroidal wound core. The size limit of energy harvesting magnetic core is: inner diameter d=[0.065,0.075]m, outer diameter D=[0.08,0.09]m, height h=[0.01,0.003]m. According to the size limit of the energy-taking magnetic core, it can be obtained: the cross-sectional area of the energy-taking magnetic core S=[S 1 ,S 2 ]=[5×10- 5 ,7.5×10- 4 ] m 2 . The magnetic path length of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation magnetic induction | aaaaa | aaaaa |

| stacking factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com