A method for making texture on silicon wafers by reusing black silicon cleaning solution

A cleaning fluid, black silicon technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve problems such as high costs, achieve simple operation, reduce texturing costs and wastewater treatment costs, The effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

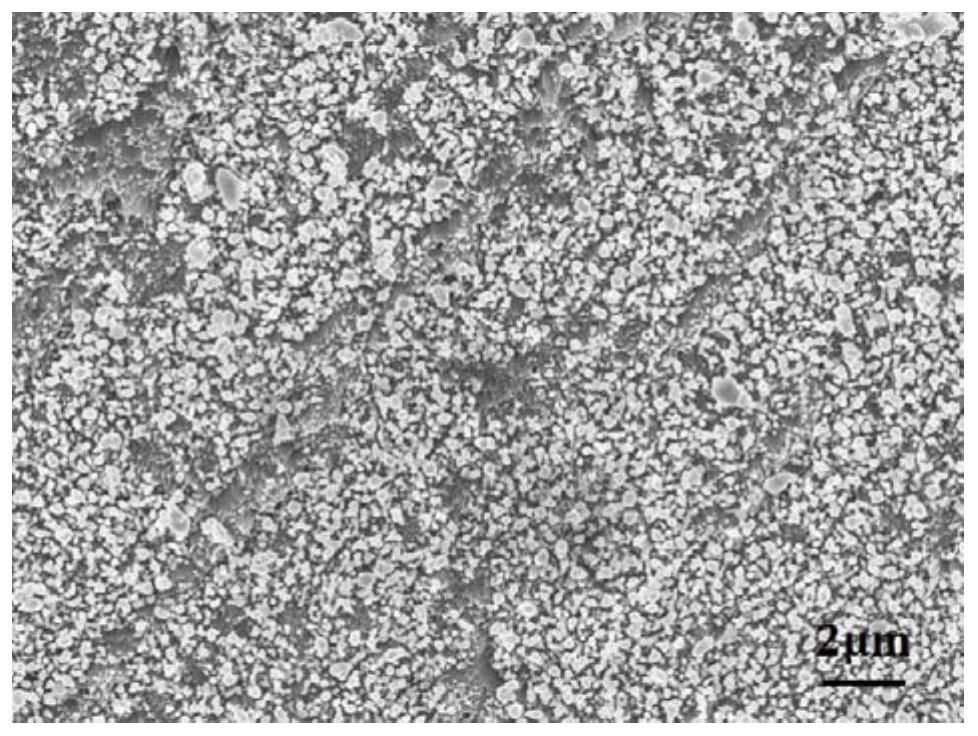

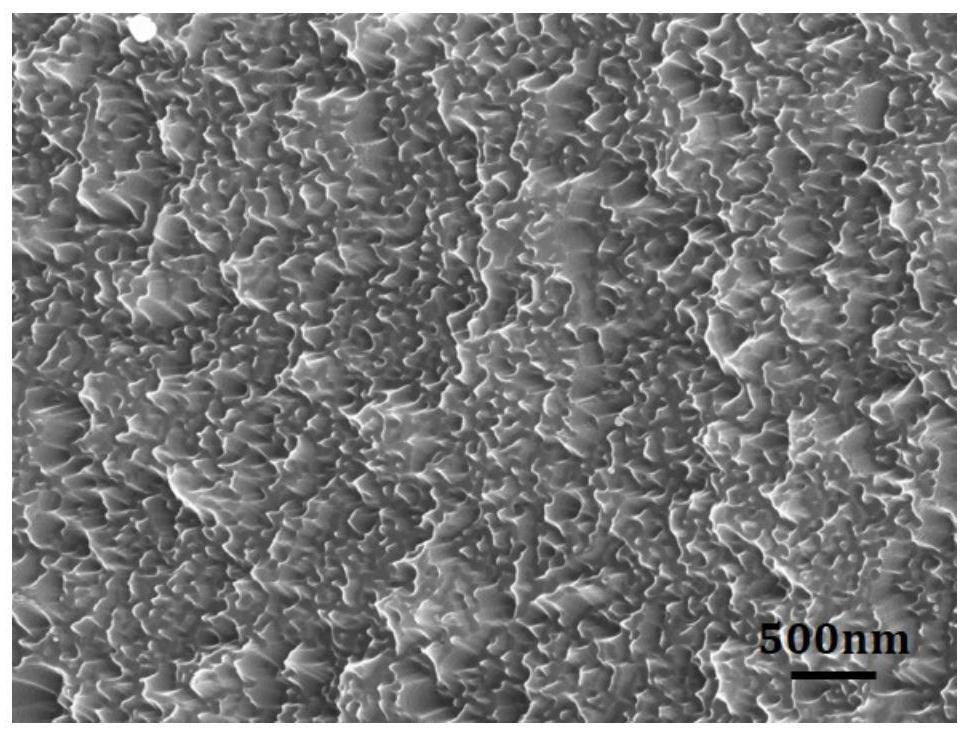

[0054] Step 1: Take a P-type diamond wire-cut polycrystalline silicon wafer (resistivity 1-3Ωcm) with a size of 156mm×156mm, and immerse it in the acidic black silicon texturing solution in the texturing tank for texturing. The reaction temperature is 25°C. The time is 5 minutes, and discretely distributed silver metal particles are formed on the surface of the silicon wafer; among them, the acidic black silicon texturing solution is prepared from silver nitrate, copper nitrate, hydrofluoric acid, nitric acid and deionized, with a total volume of 300L, nitric acid The concentration of silver was 0.5 mmol / L, the concentration of copper nitrate was 50 mmol / L, the concentration of hydrofluoric acid was 3 mol / L, and the concentration of nitric acid was 4 mol / L.

[0055] Step 2: Take out the textured silicon wafer obtained in Step 1, wash it with deionized water, and dry it with high-purity nitrogen.

[0056] Step 3: Wash the dried silicon chip obtained in step 2 with black silicon...

Embodiment 2

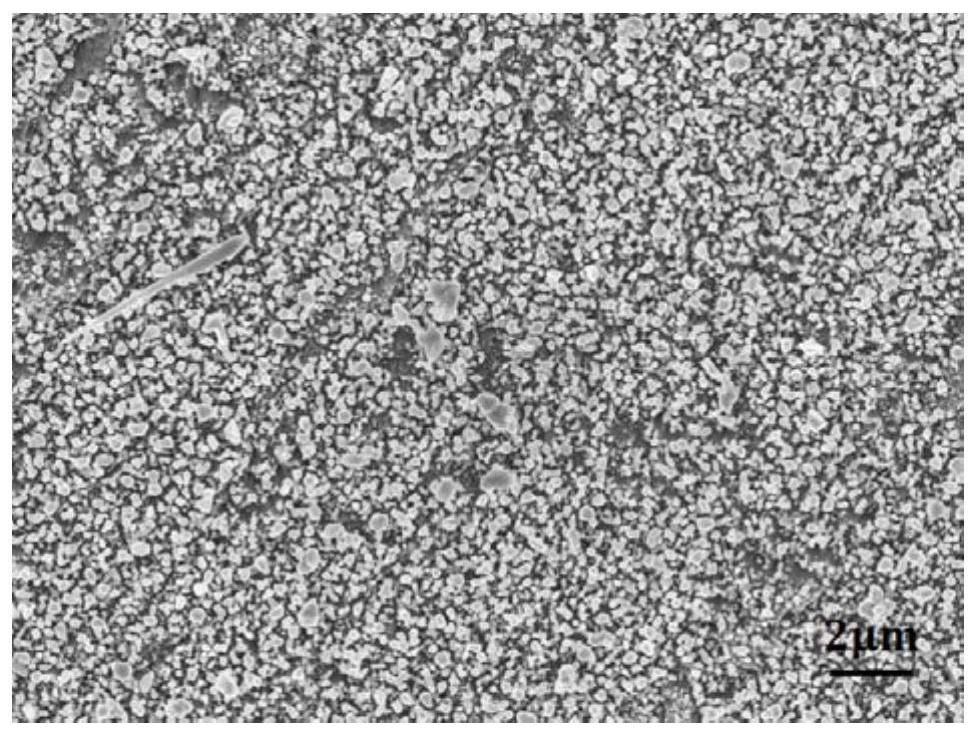

[0065] Step 1: Take a P-type diamond wire cut polysilicon wafer (resistivity 1-3Ωcm) with a size of 156mm×156mm, and immerse it in the acidic black silicon texturing solution in the texturing tank for texturing. The reaction temperature is 30°C. The time is 5 minutes, and discretely distributed silver metal particles are formed on the surface of the silicon wafer; among them, the acidic black silicon texturing solution is prepared from silver nitrate, hydrofluoric acid, nitric acid and deionized, the total volume is 200L, and the concentration of silver nitrate is The concentration of hydrofluoric acid is 0.5mmol / L, the concentration of hydrofluoric acid is 4.5mol / L, and the concentration of nitric acid is 4mol / L.

[0066] Step 2: Take out the textured silicon wafer obtained in Step 1, wash it with deionized water, and dry it with high-purity nitrogen.

[0067] Step 3: Wash the dried silicon chip obtained in step 2 with black silicon cleaning solution to remove silver metal pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com