Extraction method of nostoc sphaeroids kutz polysaccharide

An extraction method and technology of kudzu, applied in the chemical field, can solve the problems of low extraction rate of kudzu polysaccharide, poor product solubility, turbidity, etc., and achieve the effects of good moisturizing effect, antioxidant capacity, and scientific and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

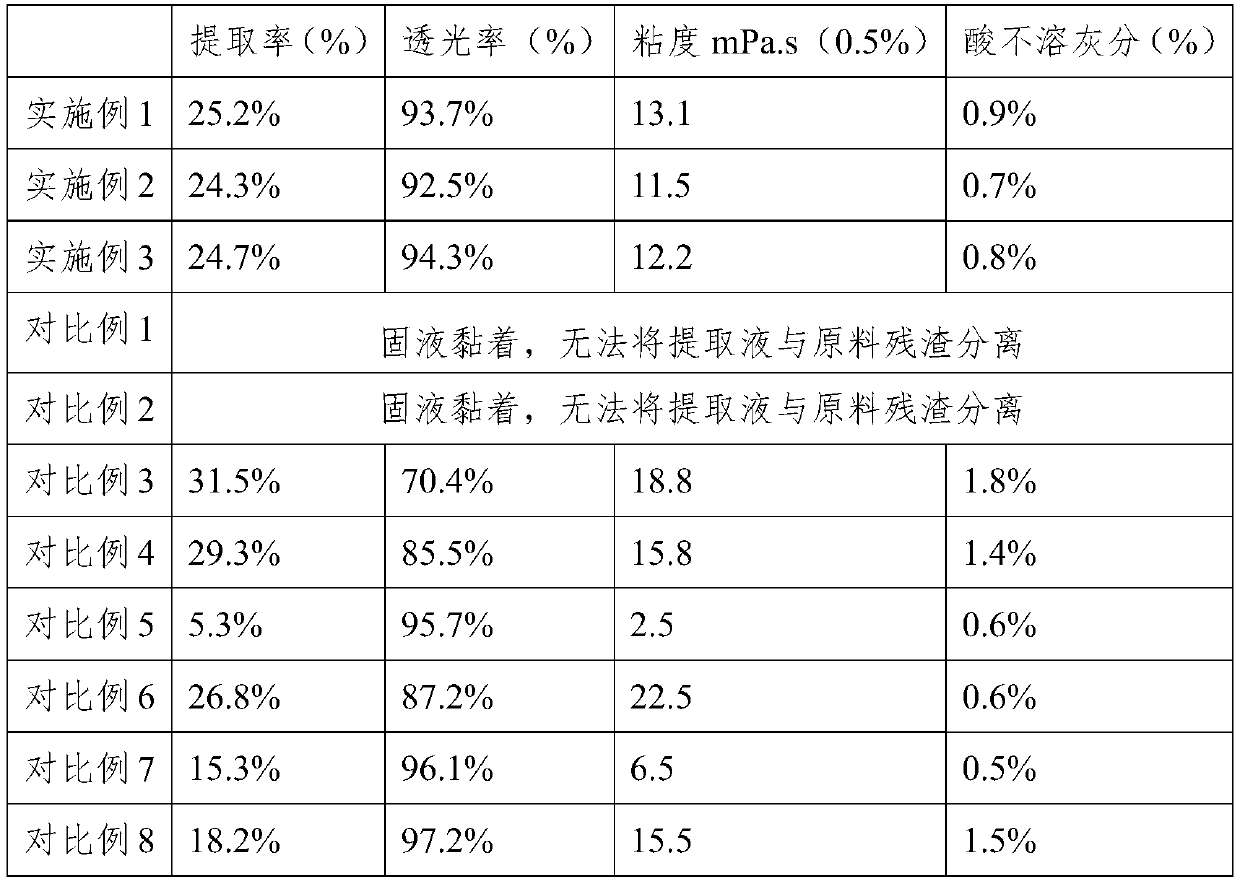

Examples

Embodiment 1

[0029] A method for extracting polysaccharides from Pueraria lobata, comprising the following steps:

[0030] S1. Pre-crushing: pulverize the dried Gexian rice product with a pulverizer to obtain Gexian rice powder;

[0031] S2. Enzymatic hydrolysis: Weigh 50g of Pueraria lobata powder in the extraction tank, add 2500ml parts by weight of pure water to dissolve, pour into 0.25% alkaline protease after dissolution, and adjust the pH of the material solution to 8 with sodium hydroxide. Put it in a 52℃ water bath and stir for 1.5h; after enzymolysis, adjust the pH of the material solution to 6.0, increase the temperature to 85℃ and keep it for 0.5h; then add a high-temperature amylase solution with a volume fraction of 0.5%, and hydrolyze at 85℃ for 1h , To obtain the Gexianmi enzymatic hydrolysis mixture;

[0032] S3. Acidolysis and decolorization: Add 0.6% 6% dilute hydrochloric acid to the mixture of Gexianmi enzymatic hydrolysis, and stir evenly; then add 1000ppm ClO 2 The solution...

Embodiment 2

[0039] A method for extracting polysaccharides from Pueraria lobata, comprising the following steps:

[0040] S1. Pre-crushing: pulverize the dried Gexian rice product with a pulverizer to obtain Gexian rice powder;

[0041] S2. Enzymatic hydrolysis: Weigh 50g of Pueraria lobata powder in an extraction tank, add 2000ml parts by weight of pure water to dissolve, pour into 0.25% alkaline protease after dissolution, and adjust the pH of the material solution to 7.5 with sodium hydroxide. Put it in a 50℃ water bath and stir for 1 hour; after the enzymolysis, adjust the pH of the material solution to 6.0, raise the temperature to 85℃ and keep it for 0.4h; then add a high-temperature amylase solution with a volume fraction of 0.5%, and hydrolyze at 85℃ for 0.8h , To obtain the Gexianmi enzymatic hydrolysis mixture;

[0042] S3. Acidolysis and decolorization: Add 0.6% 6% dilute hydrochloric acid to the mixture of Gexianmi enzymatic hydrolysis, and stir evenly; then add 1000ppm ClO 2 The so...

Embodiment 3

[0049] A method for extracting polysaccharides from Pueraria lobata, comprising the following steps:

[0050] S1. Pre-crushing: pulverize the dried Gexian rice product with a pulverizer to obtain Gexian rice powder;

[0051] S2. Enzymatic hydrolysis: Weigh 50g of Pueraria lobata powder in the extraction tank, add 2500ml parts by weight of pure water to dissolve, pour into 0.25% alkaline protease after dissolution, adjust the pH of the material liquid to 8.5 with sodium hydroxide, Put it in a 55℃ water bath and stir for 2h; after the enzymolysis, adjust the pH of the material solution to 6.0, heat up to 85℃ and keep it for 0.6h; then add 0.5% high-temperature amylase solution and hydrolyze at 85℃ for 1.2h , To obtain the Gexianmi enzymatic hydrolysis mixture;

[0052] S3. Acidolysis and decolorization: Add 0.6% 6% dilute hydrochloric acid to the mixture of Gexianmi enzymatic hydrolysis, and stir evenly; then add 1000ppm ClO 2 The solution was stirred at 80°C for 2h to obtain a primar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com