Preparation method of cationic blue dye

A blue dye, cation technology, applied in the field of preparation of cation blue dye, can solve the problems of high COD, high chroma, environmental threats and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

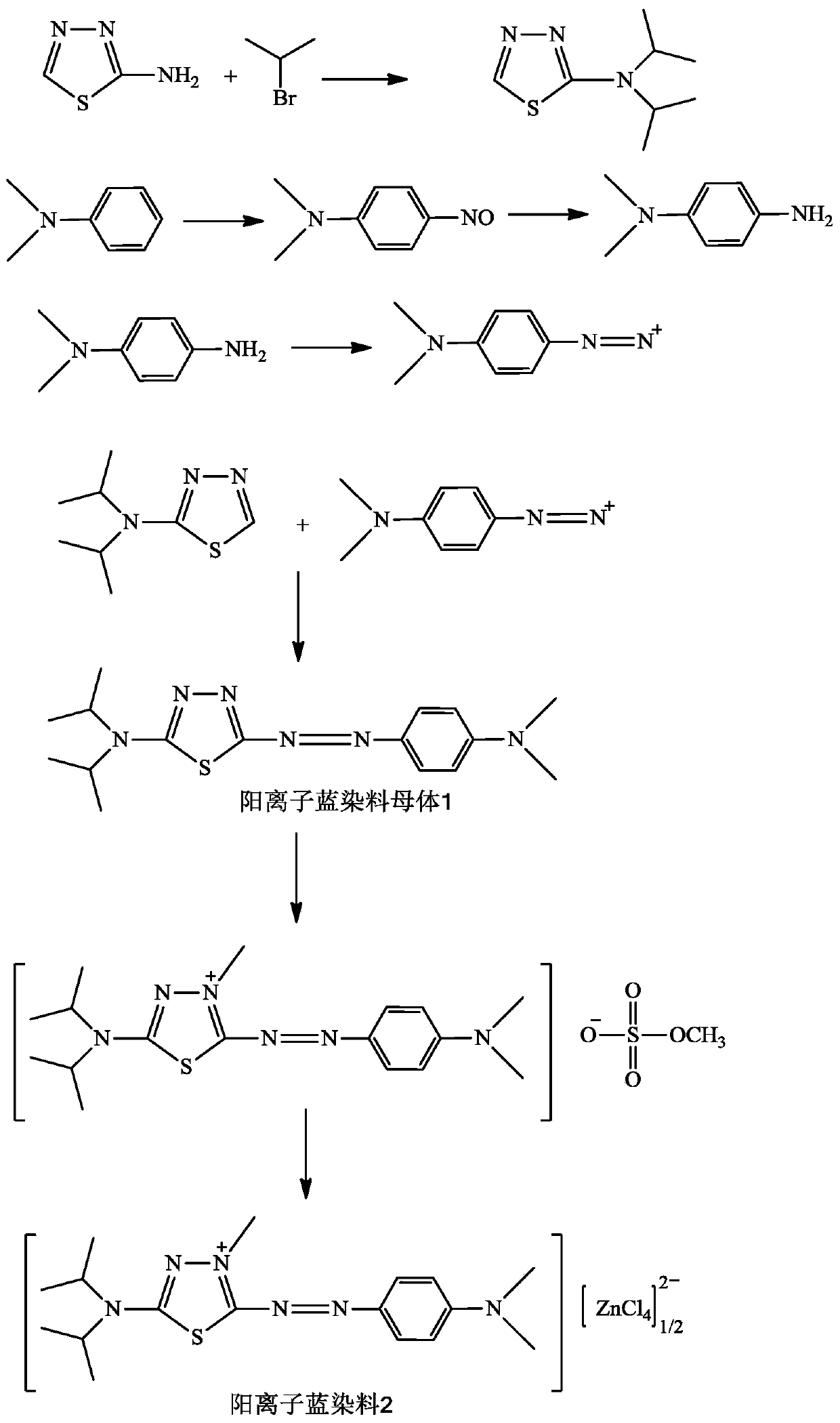

Method used

Image

Examples

Embodiment 1

[0141] (1) Preparation of 4-(dimethylamino)benzenediazonium chloride

[0142] Add 1mol of N,N-dimethylaniline and 400mL of 37% concentrated hydrochloric acid into a 1L three-necked flask, drop 200mL of aqueous solution of 1.04mol of sodium nitrite into the reaction solution, and keep the dropping temperature at (- 5°C)-0°C, react at 0°C-5°C for 2 hours, after the reaction, filter with suction and dry to obtain N,N-dimethyl-4-nitrosoaniline.

[0143] Add 1mol of N,N-dimethyl-4-nitrosoaniline, 600mL of water and 600mL of 37% concentrated hydrochloric acid into a 2L three-necked flask, add 2.6mol of zinc powder into the reaction solution, and keep the reaction The temperature was 20°C-25°C for 4 hours. After the reaction, 4 mol of sodium hydroxide was added to adjust the pH to 7-8, filtered by suction, and dried to obtain N,N-dimethyl-p-phenylenediamine.

[0144] Add 1mol of N,N-dimethyl-p-phenylenediamine and 400mL of 37% concentrated hydrochloric acid into a 1L three-neck flas...

Embodiment 2

[0152] (1) Preparation of 4-(diethylamino)benzenediazonium chloride

[0153] Add 1mol of N,N-diethylaniline and 400mL of 37% concentrated hydrochloric acid into a 1L three-necked flask, add 1.04mol of sodium nitrite in 200mL of aqueous solution dropwise into the reaction solution, and keep the dropping temperature at (- 5°C)-0°C, react at 0°C-5°C for 2 hours, after the reaction, filter with suction and dry to obtain N,N-diethyl-4-nitrosoaniline.

[0154] Add 1mol of N,N-diethyl-4-nitrosoaniline, 600mL of water and 600mL of 37% concentrated hydrochloric acid into a 2L three-necked flask, add 2.6mol of zinc powder into the reaction solution, and keep the reaction The temperature was 20°C-25°C for 4 hours. After the reaction, 4 mol of sodium hydroxide was added to adjust the pH to 7-8, suction filtered, and dried to obtain N,N-diethyl-p-phenylenediamine.

[0155]

[0156]Add 1mol of N,N-diethyl-p-phenylenediamine and 400mL of 37% concentrated hydrochloric acid into a 1L three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com