Method for preparing immobilized enzyme from zeolite imidazate skeleton compound

A skeleton compound, zeolite imidazolate technology, applied in the direction of fixing on or in the inorganic carrier, fixing on/in the organic carrier, etc., can solve the problems of unfavorable recovery and recycling, difficult separation and purification, poor stability, etc. Achieve the effect of cost-effective, simple operation and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

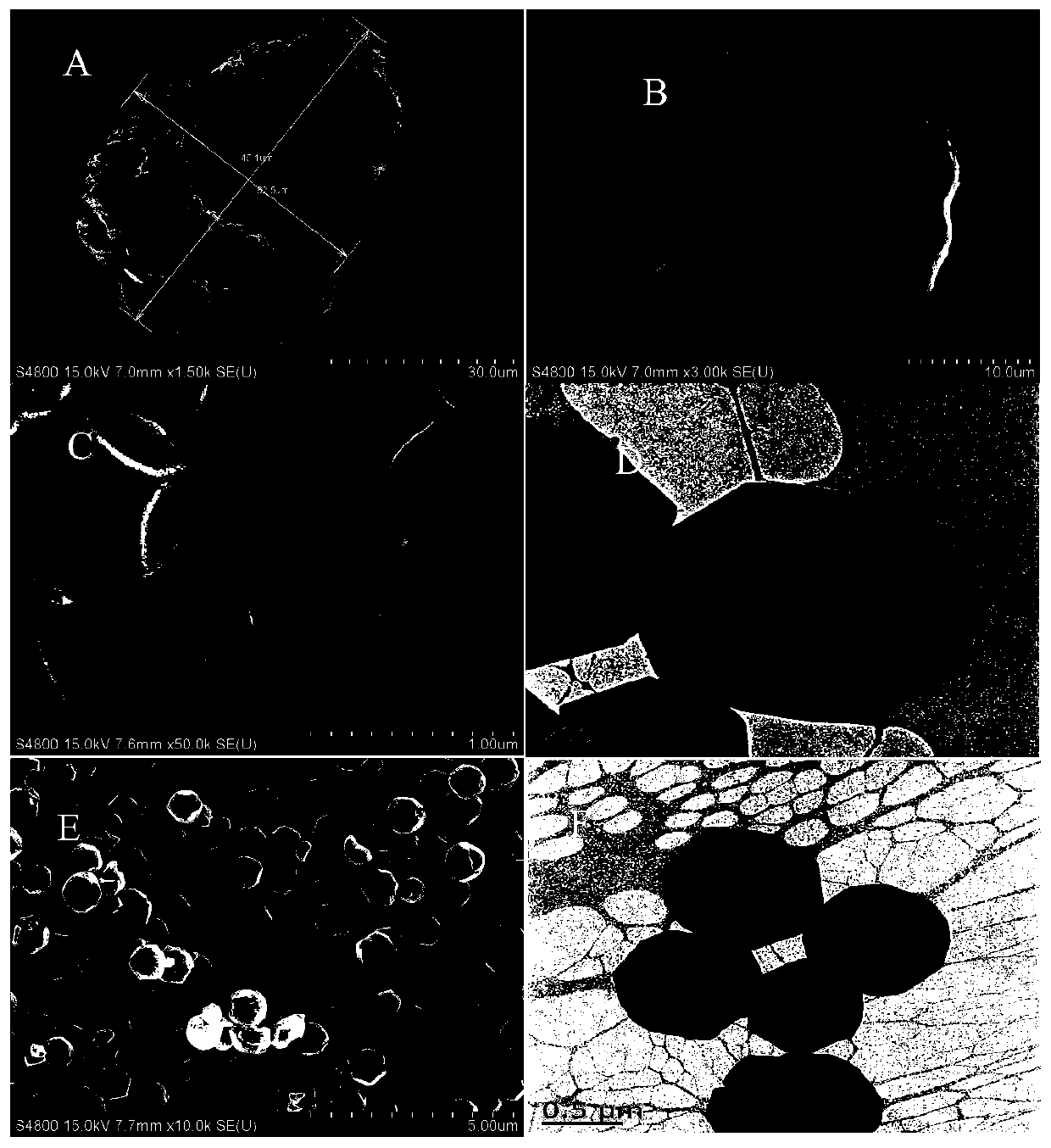

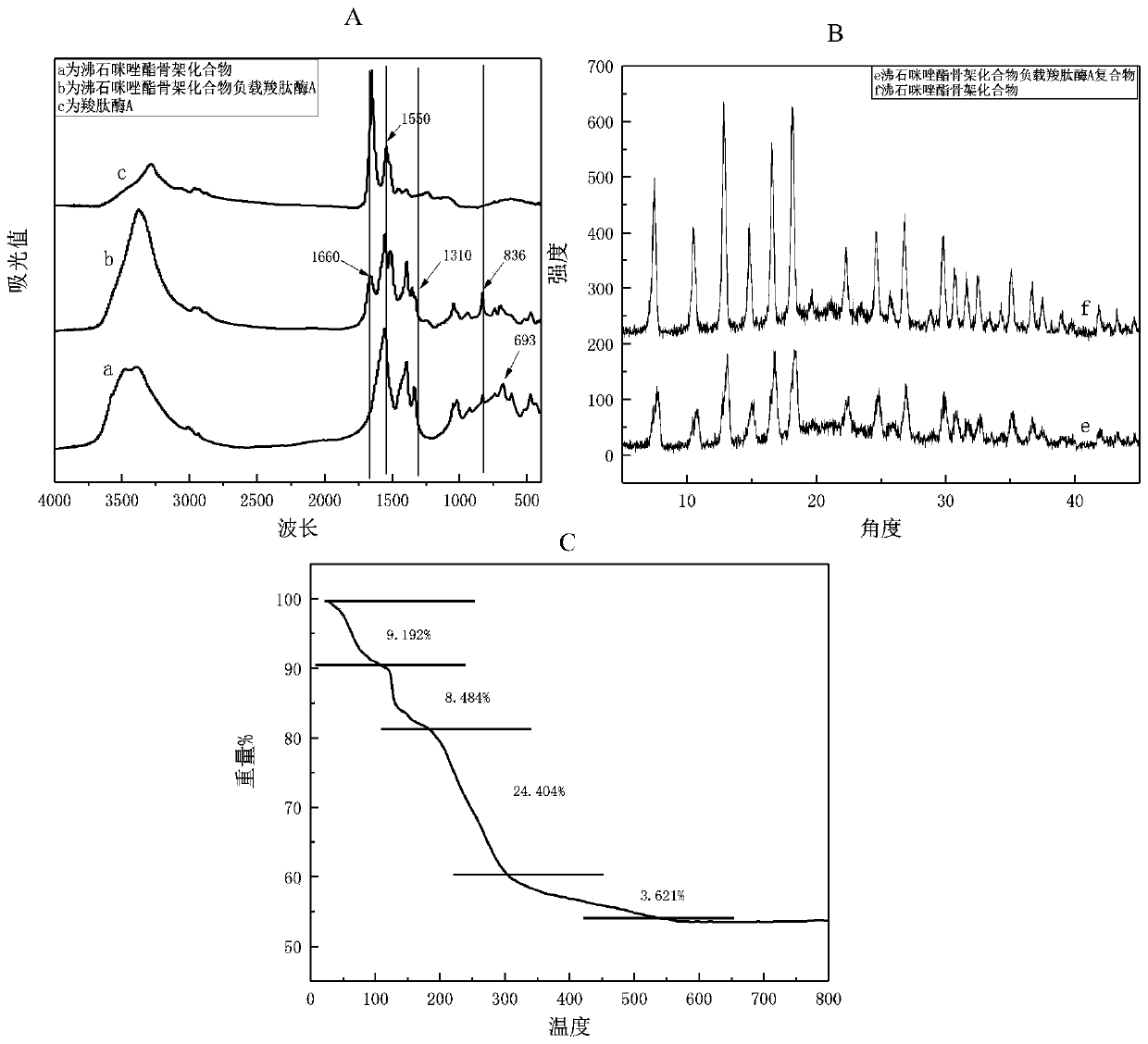

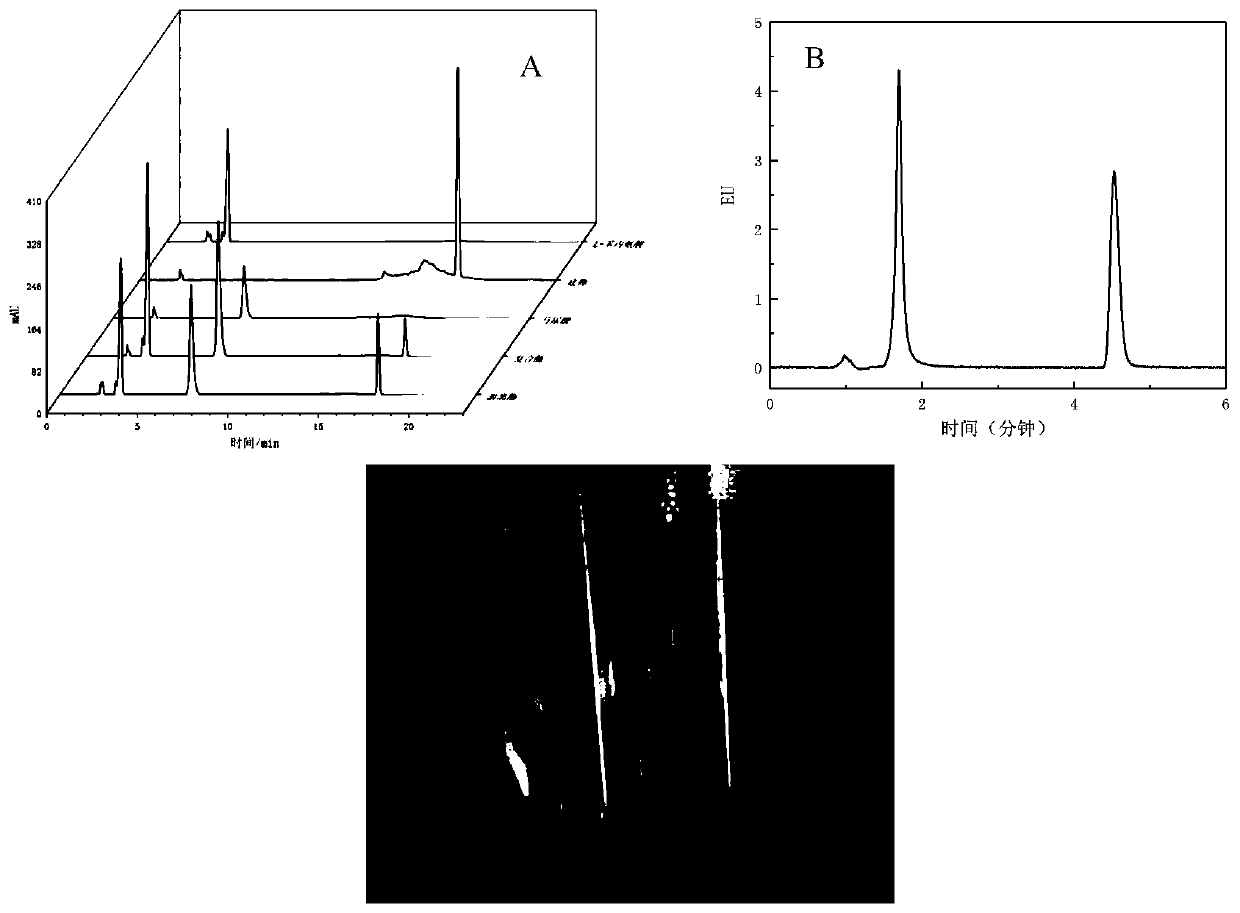

[0028] Embodiment 1 zeolite imidazolate skeleton compound loaded carboxypeptidase A complex synthesis

[0029] (1) Weigh 0.0657g of 2-methylimidazole and add 5ml of ultrapure water to make 2-methylimidazole aqueous solution, take 0.439g of zinc acetate and add 5ml of ultrapure water to make zinc acetate aqueous solution, and make 1mL concentration 15mg / mL polyethylene glycol aqueous solution;

[0030] (2) Use a pipette gun to take 960 microliters (0.025g) of the enzyme stock solution, put it in a 1.5mL centrifuge tube and centrifuge for 5 minutes, remove the supernatant, and dissolve the 1mL volume of polyethylene glycol prepared in step (1) The aqueous solution is added to the centrifuge tube, and ultrasonicated for 15 minutes to form a polyethylene glycol / carboxypeptidase A complex solution of polyethylene glycol-coated carboxypeptidase A;

[0031] (3) Put the polyethylene glycol / carboxypeptidase A complex solution into an ultrafiltration centrifuge tube for ultrafiltration...

Embodiment 2

[0034] Example 2 Synthesis of zeolite imidazolate skeleton compound loaded carboxypeptidase A complex

[0035] (1) Weigh 1.0526g of 2-methylimidazole and add 8ml of ultrapure water to make 2-methylimidazole aqueous solution, take 0.1407g of zinc acetate and add 2ml of ultrapure water to make zinc acetate aqueous solution, and make 1mL concentration 15mg / mL polyethylene glycol aqueous solution;

[0036](2) Use a pipette gun to take 960 microliters (0.025g) of the enzyme stock solution, put it in a 1.5mL centrifuge tube and centrifuge (10000r / min) for 5 minutes, then remove the supernatant, and make the 1mL volume prepared in step (1) The polyethylene glycol aqueous solution is added in this centrifuge tube, ultrasonic 15 minutes forms the polyethylene glycol / carboxypeptidase A complex solution of polyethylene glycol encapsulation carboxypeptidase A;

[0037] (3) Put the polyethylene glycol / carboxypeptidase A complex solution into an ultrafiltration centrifuge tube for ultrafil...

Embodiment 3

[0040] Example 3 Synthesis of Carboxypeptidase A Complex Supported by Zeolite Imidazolate Skeleton Compound

[0041] (1) Weigh 1.5787g of 2-methylimidazole and add 8ml of ultrapure water to make 2-methylimidazole aqueous solution, take 0.1407g of zinc acetate and add 2ml of ultrapure water to make zinc acetate aqueous solution, and make 1mL concentration 15mg / mL polyethylene glycol aqueous solution;

[0042] (2) Use a pipette gun to take 960 microliters (0.025g) of the enzyme stock solution, put it in a 1.5mL centrifuge tube and centrifuge (10000r / min) for 5 minutes, then remove the supernatant, and make the 1mL volume prepared in step (1) The polyethylene glycol aqueous solution is added in this centrifuge tube, ultrasonic 15 minutes forms the polyethylene glycol / carboxypeptidase A complex solution of polyethylene glycol encapsulation carboxypeptidase A;

[0043] (3) Put the polyethylene glycol / carboxypeptidase A complex solution into an ultrafiltration centrifuge tube for u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com