Preparation and processing method of high-strength and high-conductivity copper alloy strip

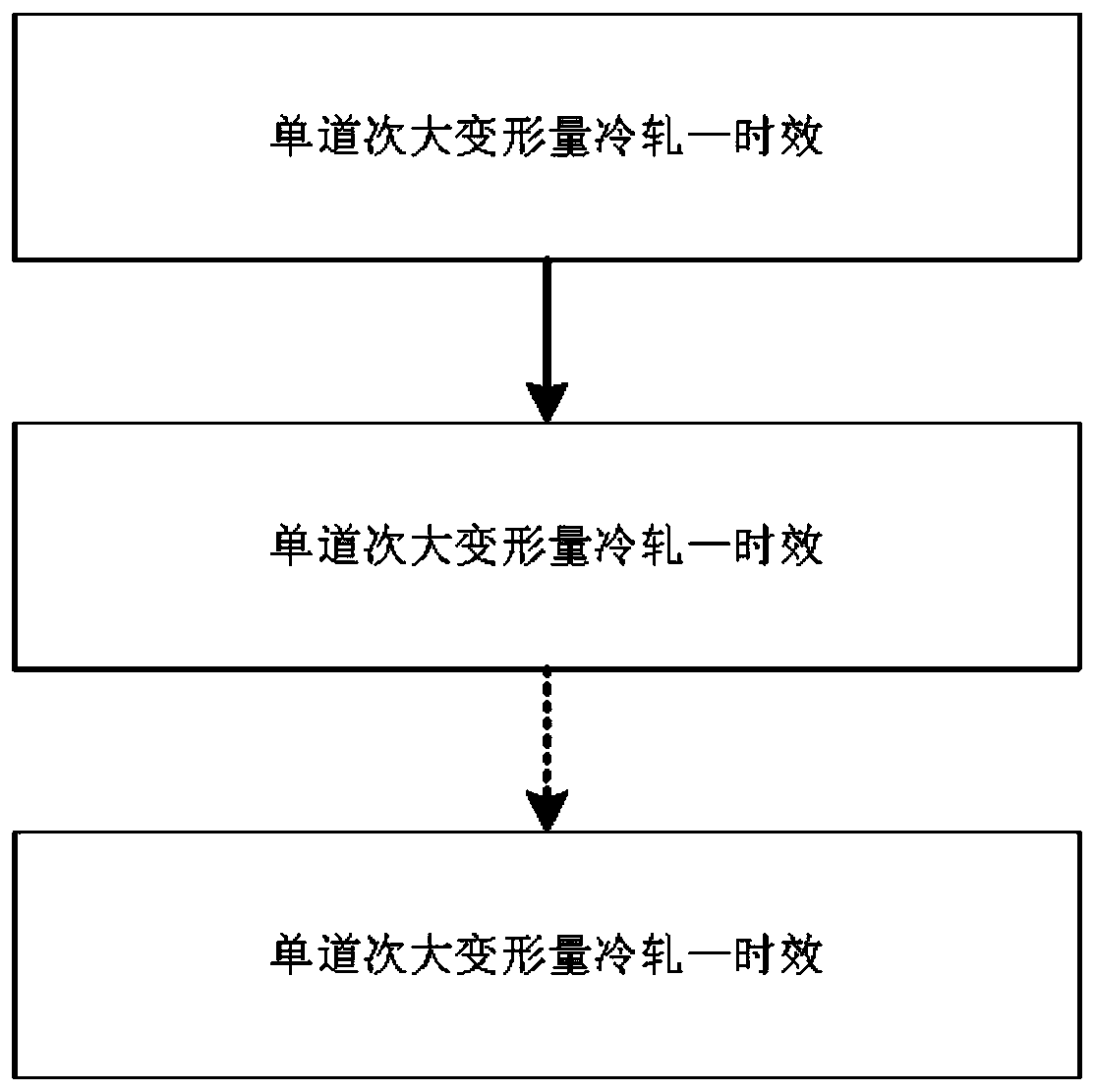

A technology of copper alloy strip material and processing method, which is applied in the direction of metal rolling, rolling force/roll gap control, etc., can solve the problems of uneven distribution of precipitated phases, difficult comprehensive performance of products, and large work hardening rate, etc., to achieve improved Mechanical properties and electrical conductivity, improving utilization and yield, and solving the effect of reducing precipitated phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Preparation of C70250 copper alloy strip with a width of 100 mm and a thickness of 0.08 mm.

[0028] The down-draw hot continuous casting technology is used to prepare C70250 copper alloy strip billet with bright surface, dense structure, continuous columnar crystal structure along the continuous casting direction, width 100mm, and thickness 8mm; the copper alloy strip billet is directly processed at room temperature A cold rolling with a secondary deformation of 97.5%; a cold-rolled copper alloy strip is subjected to an aging treatment, the aging temperature is 450℃, the aging time is 30min, and the protective gas is argon; the primary aging copper alloy strip is at room temperature The second cold rolling with a deformation of 60% is carried out to obtain a C70250 copper alloy strip with a width of 100mm and a thickness of 0.08mm; then the second cold-rolled copper alloy strip is subjected to a secondary aging treatment, and the aging temperature is 400℃ , The...

Embodiment 2

[0029] Example 2: Preparation of a KFC copper alloy strip with a width of 40 mm and a thickness of 0.16 mm.

[0030] The up-draw warm continuous casting technology is used to prepare KFC copper alloy strip blanks with smooth surface, dense structure, columnar crystal structure with high orientation along the continuous casting direction, width 40mm, thickness 4mm; direct copper alloy strip blanks at room temperature Perform a cold rolling with a pass deformation of 90%; a cold-rolled copper alloy strip is subjected to an aging treatment, the aging temperature is 470℃, the aging time is 50min, and the protective gas is argon; the primary aging copper alloy strip Perform secondary cold rolling with a pass deformation of 60% at room temperature to obtain a KFC copper alloy strip with a width of 40mm and a thickness of 0.16mm; then the secondary cold-rolled copper alloy strip is subjected to secondary aging treatment, and the aging temperature is 400℃, the aging time is 10min, and th...

Embodiment 3

[0031] Example 3: Preparation of C18150 copper alloy strip with a width of 80 mm and a thickness of 0.1 mm.

[0032] The horizontal warm continuous casting technology is used to prepare C18150 copper alloy strip blanks with smooth surface, dense structure, columnar crystal structure with high orientation along the continuous casting direction, width 80mm, thickness 8mm; copper alloy strip blanks are directly processed at room temperature One cold rolling with a pass deformation of 90%; one cold-rolled copper alloy strip is subjected to an aging treatment, the aging temperature is 460℃, the aging time is 40min, and the protective gas is argon; the one-time aging copper alloy strip is Perform secondary cold rolling with a pass deformation of 87.5% at room temperature to obtain a C18150 copper alloy strip with a width of 80 mm and a thickness of 0.1 mm; then the secondary cold rolled copper alloy strip is subjected to secondary aging treatment, and the aging temperature is 420 ℃, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com