A catalytic toluene combustion ni-α-mno 2 Synthetic method of catalyst

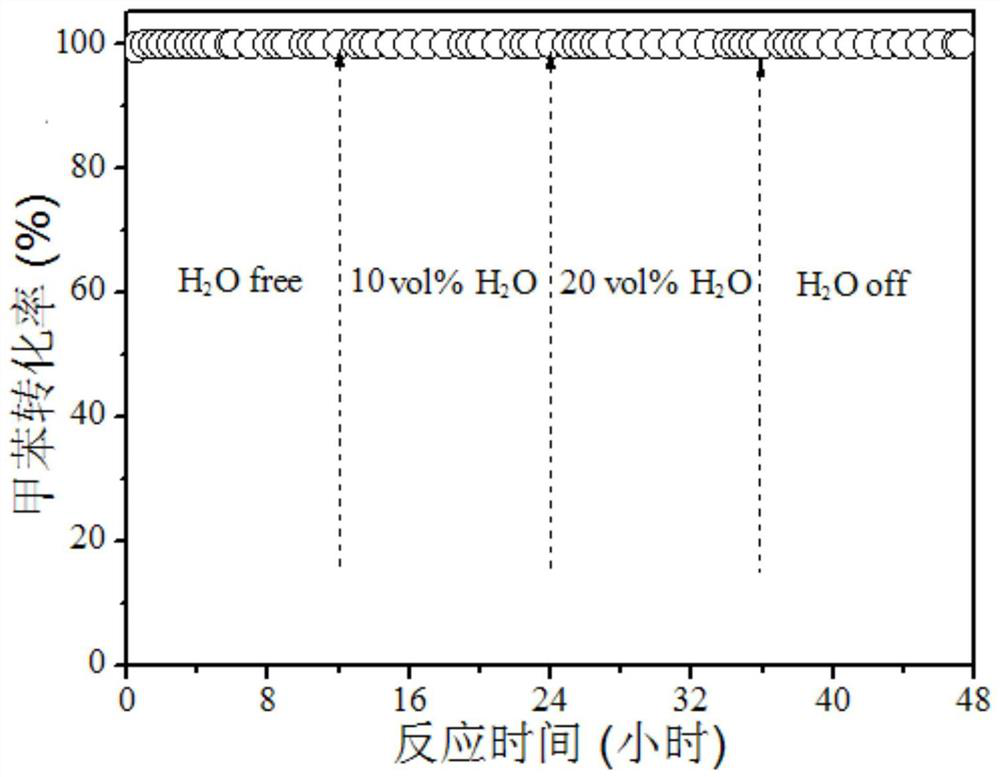

A synthesis method and catalyst technology, applied in combustion methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve problems such as poor stability and low elimination activity, and achieve good stability, The effect of low price and simple conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Embodiment 1: In this embodiment, a catalytic toluene combustion of Ni-α-MnO 2 The synthetic method of catalyst, it is realized according to the following steps:

[0022] 1. Add 15-45ml deionized water and 5-20mmol potassium permanganate into A cup, ultrasonicate for 10 minutes, and stir magnetically at room temperature to obtain a purple solution;

[0023] 2. Add 100~300ml of deionized water and 27~324mmol of ethylene glycol into cup B, stir magnetically at room temperature to obtain a transparent solution;

[0024] 3. Add the purple solution obtained in step 1 to the transparent solution obtained in step 2, stir and react for 0.5-6 h, and then add 0.5-3.0 mmol Ni 2+ metal salt, and continue stirring for 1-4 h to obtain a reaction solution;

[0025] 4. The reaction solution obtained in step 3 is filtered, and the filtered solid product is washed with deionized water until neutral, then dried at 80-105 °C for 8-24 hours, and then calcined in air at 350-650 °C for 2-6 ...

specific Embodiment approach 2

[0028] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, 25 ml of deionized water and 10 mmol of potassium permanganate are added to the A cup. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, 35 ml of deionized water and 15 mmol of potassium permanganate are added to the A cup. Other steps and parameters are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com