A kind of preparation method and application of material with friction degradation performance

A performance and composite material technology, applied in the field of preparation of catalyst materials, can solve problems such as direct utilization of triboelectric charge without research, achieve the effects of improving tribocatalytic performance, ensuring water safety, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Zinc nitrate, sodium hydroxide and ferric nitrate are mixed homogeneously with the ratio of 10g:5g:0.2g;

[0032] (2) The mixture is put into a ball mill, and ball milled at 500 rpm for 50 min;

[0033] (3) Dispersing the product into deionized water, performing suction filtration, and washing with deionized water and absolute ethanol in sequence;

[0034] (4) Collect the product and anneal at 200°C to obtain a composite material with friction degradation properties;

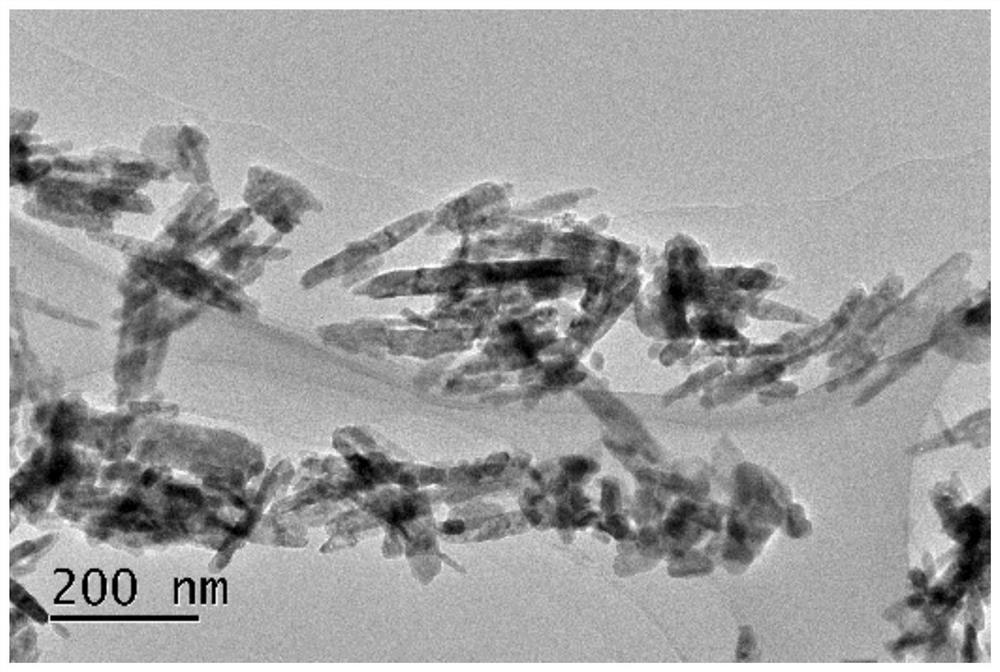

[0035] (5) The transmission electron microscope picture of the prepared material is as follows figure 1 , it can be seen that the obtained material is a rod-like structure with a length of about 200nm and a width of about 20nm.

Embodiment 2

[0037] (1) Disperse polyvinylidene fluoride powder into a mixed solvent of acetone and dimethylformamide, the ratio of acetone to dimethylformamide is 3ml:2ml, and the solid-liquid ratio is 1:100 (W / V, mg / ml).

[0038] (2) The mixed solution obtained in step (1) was heated at 80°C for 1 h, and then dispersed by ultrasonication for 2 h.

[0039] (3) Apply the mixed solution obtained in step (2) to a glass plate by drop coating, and dry at 100° C. to obtain a polymer film.

[0040] (4) Disperse the material obtained in Example 1 in the polymer solution in step (2), and the mixing ratio is 10mg: 1ml.

[0041] (5) Apply the mixed solution obtained in step (4) on a glass plate by drop coating, and dry at 100° C. to obtain a polymer composite film.

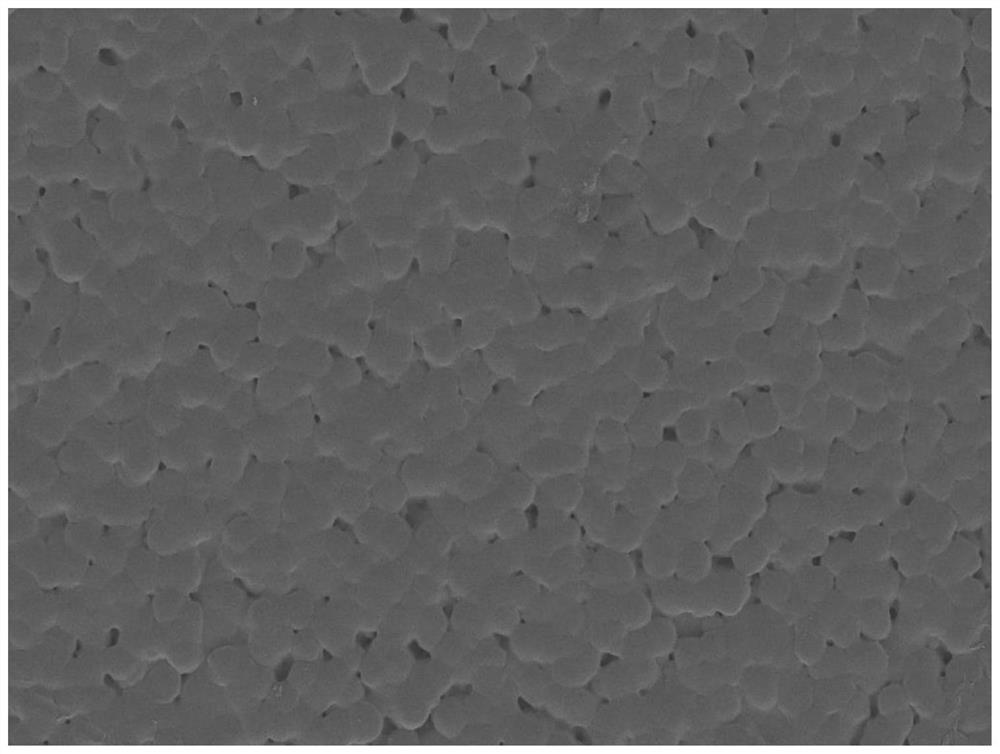

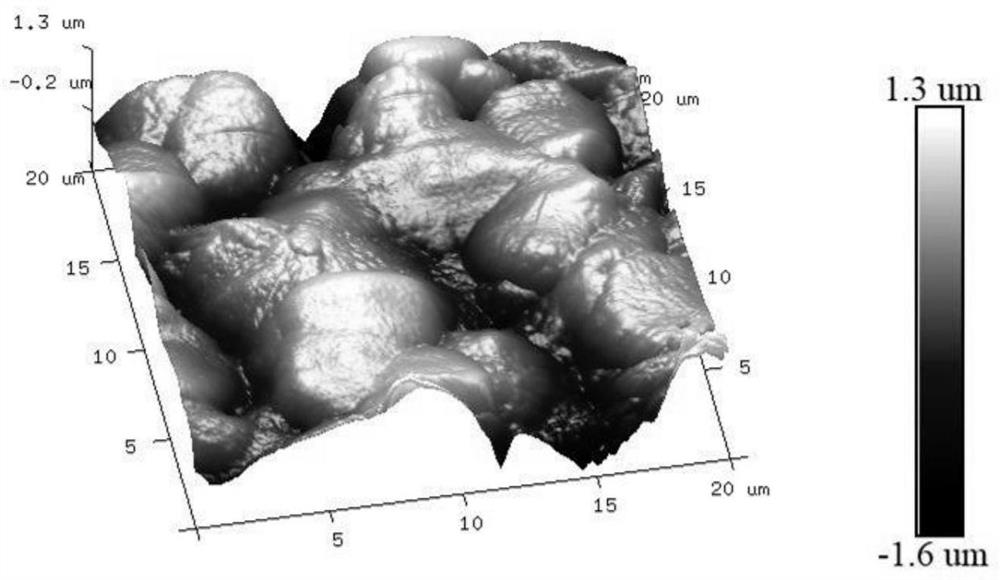

[0042]The scanning electron microscope images of the prepared polymer films are shown in figure 2 . The atomic force microscope of the prepared polymer film is shown in Figure 3(a), and the atomic force microscope of the polymer c...

Embodiment 3

[0044] (1) Disperse 50 mg of the prepared catalyst material into the EPS solution extracted from the sludge, then put it into a ball mill, and perform ball milling at a speed of 500 rpm.

[0045] (2) Every 30 minutes, take 5ml of the solution from the ball mill, centrifuge to get the supernatant, detect the protein content in the solution by Bradford method, and further analyze it in combination with three-dimensional fluorescence.

[0046] (3) The results of friction degradation of protein in EPS are as follows Figure 4 and Figure 5, from Figure 4 It can be seen from the degradation curve that with the increase of ball milling time, the protein concentration decreased significantly. After 90 minutes of reaction, the protein was basically completely degraded, which proved the effectiveness of the catalytic degradation process. From the three-dimensional fluorescence spectrum in Figure 5, it can be seen that the EPS solution has obvious fluorescence emission peaks in the try...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com