Beryllium plate surface treatment method

A treatment method and surface friction technology, applied in grinding machines, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of small amount of surface treatment, rough surface of beryllium plate, low material utilization rate, etc., to improve the accuracy of thickness and size , The thickness of the beryllium plate is controllable, and the effect of improving the surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

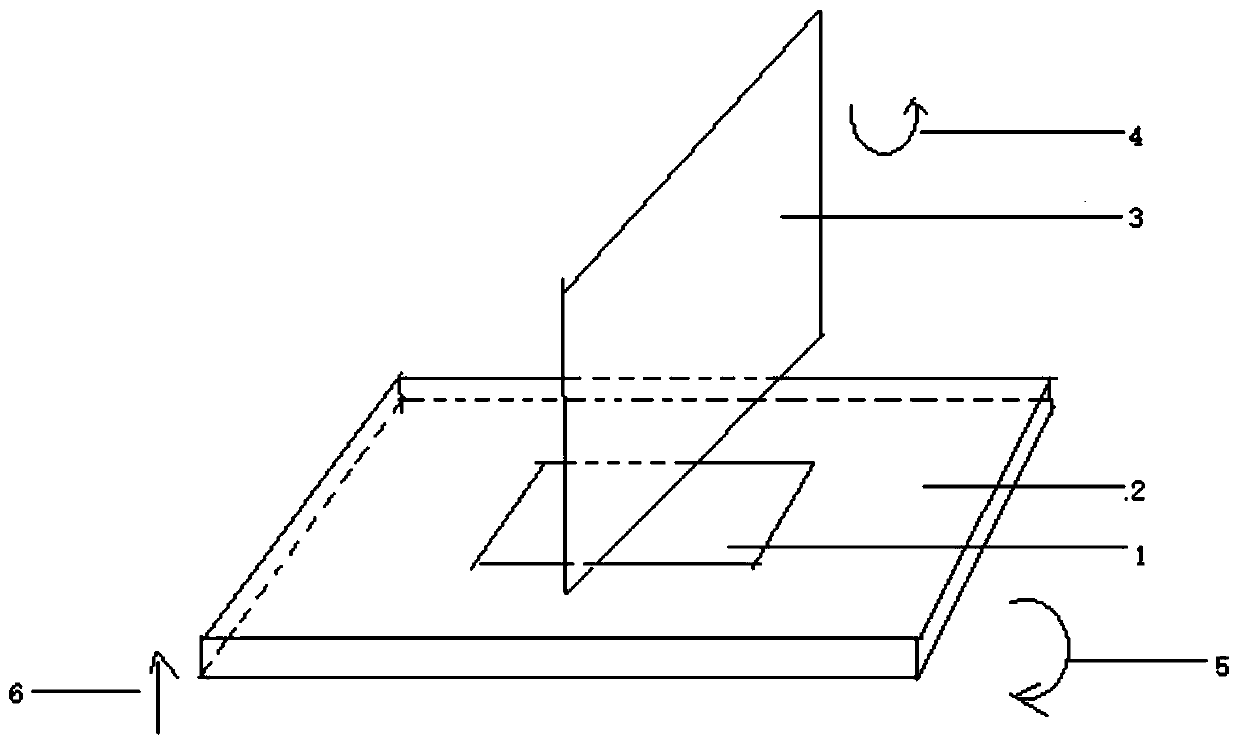

[0035] Step 1, select the beryllium plate 1 to be processed and the abrasive belt 3 driven by the motor according to the running direction 4; and place the beryllium plate 1 horizontally on the conveyor belt 2, refer to figure 1 . Among them, the size of the beryllium plate is 120mm in length, 20mm in width and 0.5mm in thickness; the model of the abrasive belt is 200 mesh.

[0036] Step 2, the abrasive belt 3 is vertically suspended on the horizontal plane of the conveyor belt 1, refer to figure 1 Carry out initial adjustment to the gap between the horizontal plane of the conveyor belt 1 and the abrasive belt 3 (the conveyor belt 2 will rise according to the adjustment direction 6, reduce the horizontal plane of the conveyor belt 2 and the gap between the abrasive belt 3) and pass the initial adjustment The conveyor belt 3 runs the horizontally placed beryllium plate to a fixed position according to the transmission direction 5 for positioning and fixing, refer to figure 2...

Embodiment 2

[0049] Step 1, select the beryllium plate 1 to be processed and the abrasive belt 3 driven by the motor according to the running direction 4; and place the beryllium plate 1 horizontally on the conveyor belt 2, refer to figure 1 . Among them, the size of the beryllium plate is 160mm in length, 60mm in width and 0.1mm in thickness; the model of the abrasive belt is 400 mesh.

[0050] Step 2, the abrasive belt 3 is vertically suspended on the horizontal plane of the conveyor belt 1, refer to figure 1 Carry out initial adjustment to the gap between the horizontal plane of the conveyor belt 1 and the abrasive belt 3 (the conveyor belt 2 will rise according to the adjustment direction 6, reduce the horizontal plane of the conveyor belt 2 and the gap between the abrasive belt 3) and pass the initial adjustment The conveyor belt 3 runs the horizontally placed beryllium plate 1 to a fixed position according to the transmission direction 5 for positioning and fixing, refer to figure...

Embodiment 3

[0063] Step 1, select the beryllium plate 1 to be processed and the abrasive belt 3 driven by the motor according to the running direction 4; and place the beryllium plate 1 horizontally on the conveyor belt 2, refer to figure 1 . Among them, the size of the beryllium plate is 200mm in length, 100mm in width and 2.0mm in thickness; the model of the abrasive belt is 500 mesh.

[0064] Step 2, the abrasive belt 3 is vertically suspended on the horizontal plane of the conveyor belt 1, refer to figure 1 After the initial adjustment of the gap between the horizontal plane of the conveyor belt 1 and the abrasive belt 3 (that is, the conveyor belt 2 rises according to the adjustment direction 6, and the gap between the horizontal plane of the conveyor belt 2 and the abrasive belt 3 is reduced) The conveyor belt 3 runs the horizontally placed beryllium plate 1 to a fixed position according to the transmission direction 5 for positioning and fixing, refer to figure 2 . Wherein, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com