Photo KT plate and preparing method and application of photo KT plate

A photo and board core technology, applied in the field of photo KT board and its preparation, can solve the problems of inability to use UV printers, affecting yield and efficiency, poor stiffness of KT boards, etc. , Improve the effect of stiffness and flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

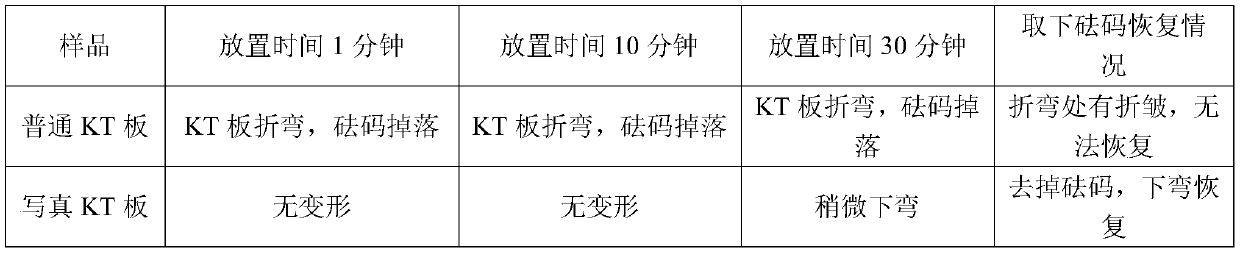

Examples

Embodiment 1

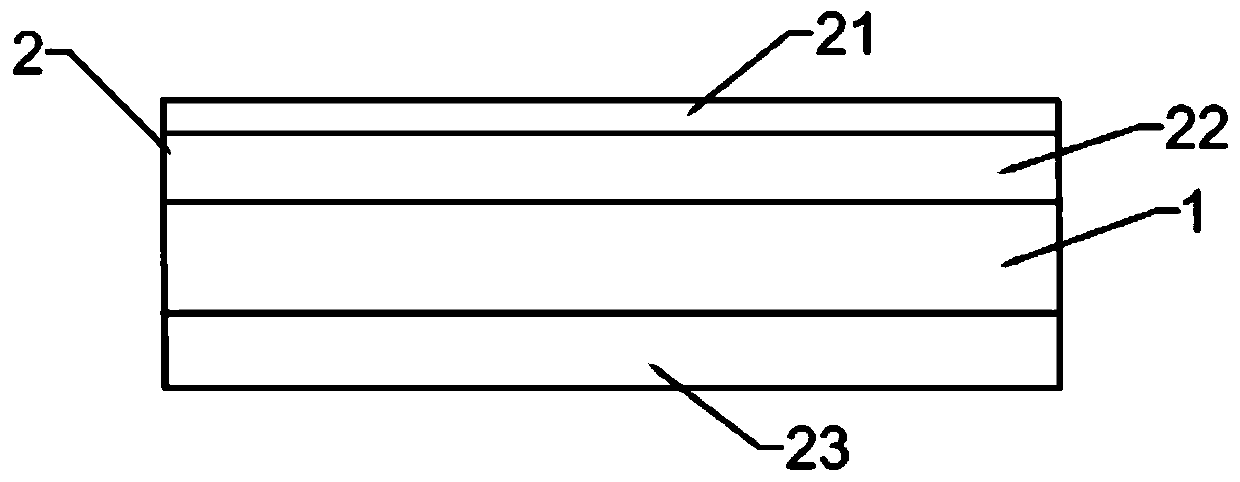

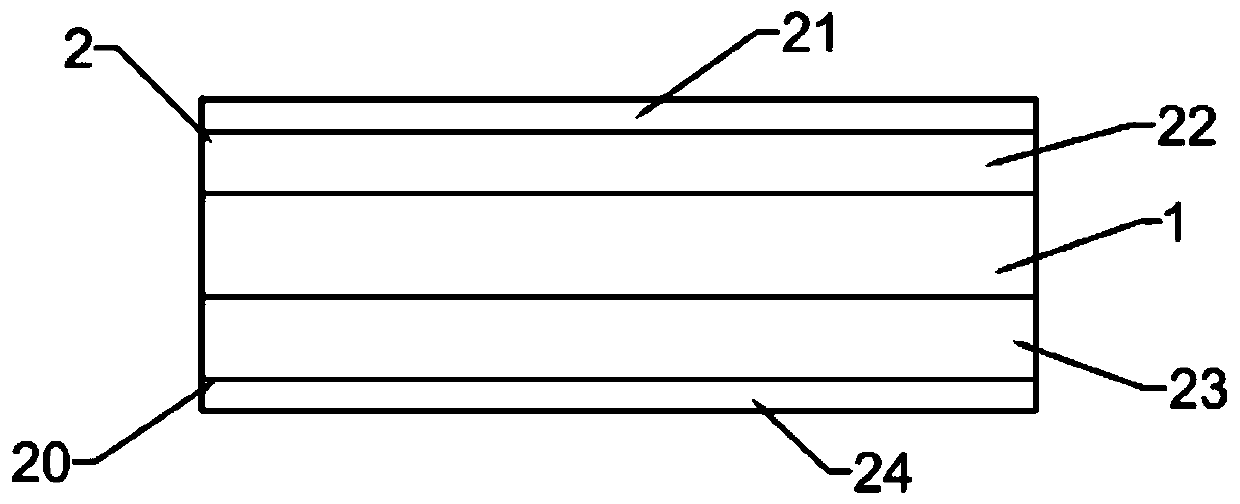

[0033] A kind of photo KT board, comprises plate core layer 1, first material layer 2 and second material layer 20, as figure 1 As shown, the first material layer 2 and the second material layer 20 are respectively heated and pressed on the upper and lower surfaces of the core layer 1 by ethylene-vinyl acetate copolymer;

[0034] Among them, the ethylene-ethyl acetate copolymer used is the adhesive, which is an environmentally friendly hot-melt adhesive, which can effectively prevent the remaining small molecular components and solvents from corroding the surface layer, resulting in the phenomenon of board layer wrapping;

[0035] The first material layer 2 comprises a first white film layer 21 and a first dragon cardboard layer 22, the first white film layer 21 is heated and pressed on the upper surface of the first dragon cardboard layer 22 by ethylene-vinyl acetate copolymer, and The first dragon cardboard layer 22 is arranged close to the board core layer 1;

[0036] The ...

Embodiment 2

[0047] A kind of photo KT board, comprises plate core layer 1, first material layer 2 and second material layer 20, as figure 1 As shown, the first material layer 2 and the second material layer 20 are respectively laminated on the upper and lower surfaces of the core layer 1 by ethylene-vinyl acetate copolymer;

[0048] Among them, the ethylene-ethyl acetate copolymer used is the adhesive, which is an environmentally friendly hot-melt adhesive, which can effectively prevent the remaining small molecular components and solvents from corroding the surface layer, resulting in the phenomenon of board layer wrapping;

[0049] The first material layer 2 comprises a first white film layer 21 and a first dragon cardboard layer 22, the first white film layer 21 is pressed on the upper surface of the first dragon cardboard layer 22 by ethylene-vinyl acetate copolymer, and the second Yilong cardboard layer 22 is set close to the board core layer 1;

[0050] The second material layer 20...

Embodiment 3

[0061] A kind of photo KT board, comprises plate core layer 1, first material layer 2 and second material layer 20, as figure 1 As shown, the first material layer 2 and the second material layer 20 are respectively laminated on the upper and lower surfaces of the core layer 1 by ethylene-vinyl acetate copolymer;

[0062] Among them, the ethylene-ethyl acetate copolymer used is the adhesive, which is an environmentally friendly hot-melt adhesive, which can effectively prevent the remaining small molecular components and solvents from corroding the surface layer, resulting in the phenomenon of board layer wrapping;

[0063] The first material layer 2 comprises a first white film layer 21 and a first dragon cardboard layer 22, the first white film layer 21 is pressed on the upper surface of the first dragon cardboard layer 22 by ethylene-vinyl acetate copolymer, and the second Yilong cardboard layer 22 is set close to the board core layer 1;

[0064] The second material layer 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com