A waste heat recovery power generation heat exchanger

A heat exchanger and waste heat recovery technology, which is applied in the direction of heat exchanger fixing, heat exchanger sealing device, heat exchange equipment, etc., can solve the problem of single waste heat extraction method, and achieve the effect of good sealing and improving heat exchange efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

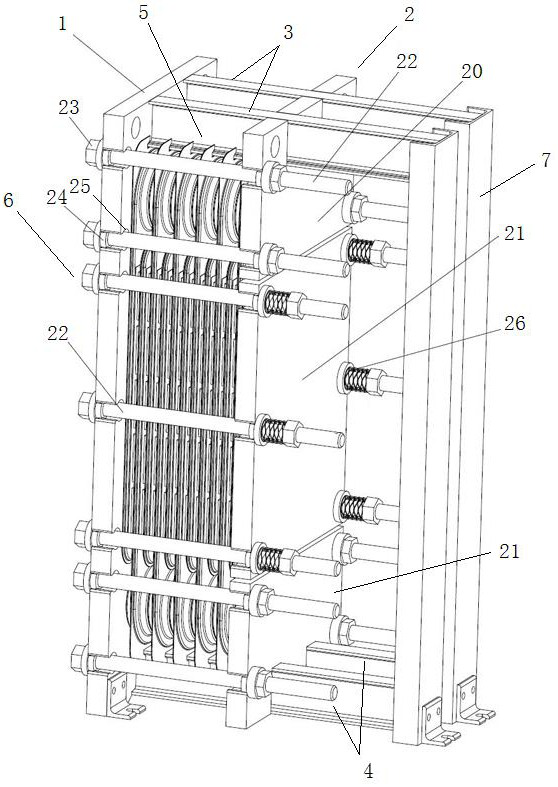

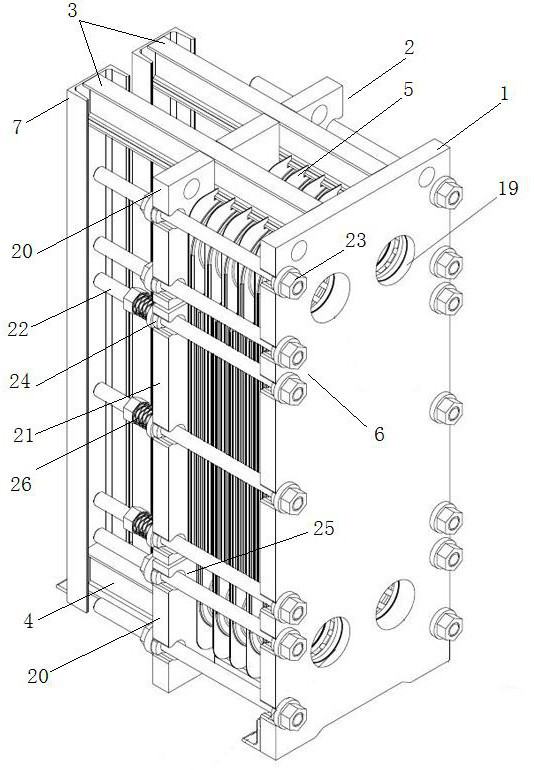

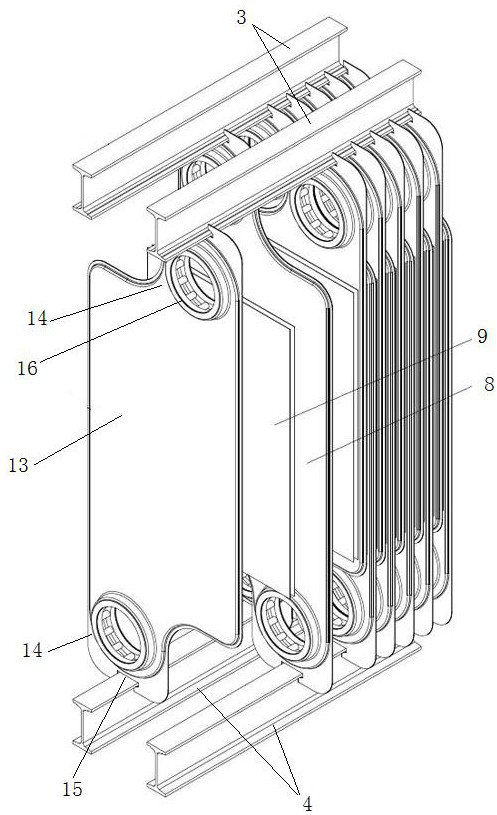

[0019] The waste heat recovery generating heat exchanger of the present invention is provided by providing two different temperatures of fluid (heat and cold) heat exchanger, and the thermoelectric module is placed between the two heat exchange sheets, and the heat flow is passed through the Selbeck effect. The temperature difference between the two sides of the module is converted to a potential difference, thereby generating electrical energy. Such a heat exchanger can extract electricity in the waste heat of internal combustion engine, industrial waste heat.

[0020] The invention will now be explained in more detail by depicting and referring to the accompanying drawings.

[0021] The waste heat recovery power generation heat exchanger includes a fixed clamping plate 1, a movable clamping plate 2, two upper beam 3, two lower beams 4, plate beam 5, clamping device 6, a column 7, the upper beam 3 is connected to the upper end of the upper portion of the active clamping plate 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com