Balance control method and system for dichlorosilane in polysilicon production

A technology of dichlorosilane and balance control, applied in the direction of halosilane, chemical instruments and methods, silicon compounds, etc., can solve problems such as unreasonable control of dichlorodihydrogen silicon, abnormal increase of polysilicon products, fluctuation of system parameters, etc., to achieve Guaranteed processing and utilization, reduced safety risks, and low equipment failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment also provides a system used in the balance control method of dichlorosilane in polysilicon production, including:

[0054] A chemical vapor deposition reactor, used for preparing polysilicon by chemical vapor deposition reaction;

[0055] The desorption tower is connected with the chemical vapor deposition reactor, and the tail gas for preparing polysilicon in the chemical vapor deposition reactor flows into the desorption tower, and the desorption tower is used for decomposing hydrogen chloride, and hydrogen chloride is obtained at the top of the desorption tower;

[0056] The first tail gas condensate separation tower is connected with the tower still of the analysis tower, the first tail gas condensate separation tower is used for rectification, and silicon tetrachloride is obtained in the tower still of the first tail gas condensate separation tower;

[0057] The second tail gas condensate separation tower is connected to the top of the first tail ga...

Embodiment 2

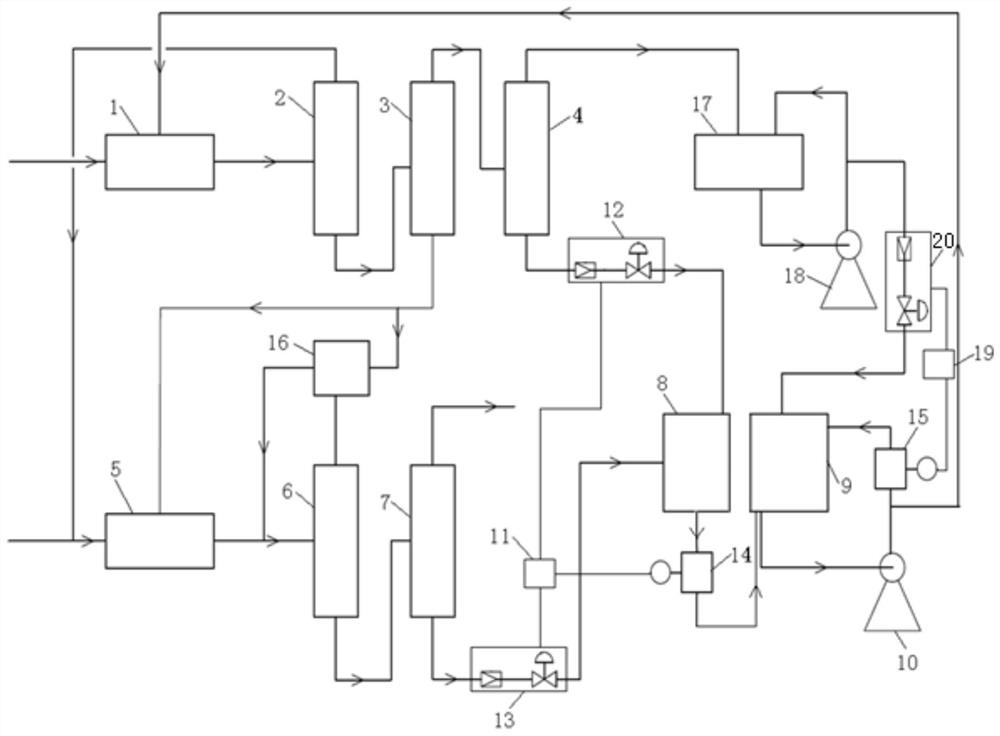

[0076] Such as figure 1 As shown, the present embodiment provides a system for the above-mentioned balance control method of dichlorosilane in polysilicon production, including:

[0077] Chemical vapor deposition reactor 1, used for preparing polysilicon by chemical vapor deposition reaction;

[0078] The analysis tower 2 is connected with the chemical vapor deposition reactor 1, and the tail gas for preparing polysilicon in the chemical vapor deposition reactor 1 flows in the analysis tower 2, and the analysis tower 2 is used for analyzing hydrogen chloride, and hydrogen chloride is obtained at the top of the analysis tower 2;

[0079] The first tail gas condensate separation tower 3 is connected with the tower still of the analysis tower 2, and the first tail gas condensate separation tower 3 is used for rectification, and silicon tetrachloride is obtained in the tower still of the first tail gas condensate separation tower 3;

[0080] The second tail gas condensate separat...

Embodiment 3

[0119] This embodiment provides a method for controlling the balance of dichlorosilane in polysilicon production using the system in Embodiment 2. The difference from the method in Embodiment 2 is:

[0120] The first preset molar percentage content of dichlorodihydrosilane is 8.3%; the second preset molar percentage content of dichlorodihydrosilane is 3.8%.

[0121] The temperature of the chemical vapor deposition reaction is 100°C and the pressure is 0.45MPa;

[0122] The temperature in the desorption tower is 122°C and the pressure is 0.9MPa;

[0123] The temperature in the first tail gas condensate separation tower is 135°C and the pressure is 0.78MPa;

[0124] The temperature of the second tail gas condensate separation tower is 84.5°C and the pressure is 0.45MPa.

[0125] The temperature of the cold hydrogenation reaction is 450°C and the pressure is 2.5MPa;

[0126] The temperature in the trichlorosilane separation tower is 62.5°C and the pressure is 0.23MPa;

[0127...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com